Mechanical spiral door bolt mechanism for safe box and cabinet

A safe and mechanical technology, applied in door/window accessories, building structure, handle connection, etc., can solve the problems of troublesome operation and assembly, many parts, etc., and achieve the effect of increasing processing cost, small size and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

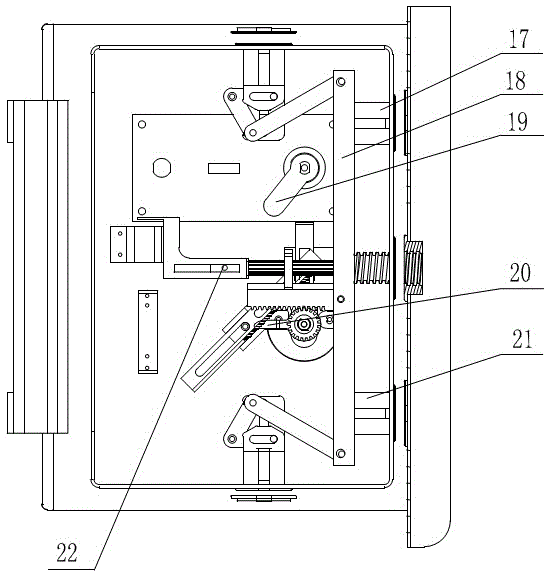

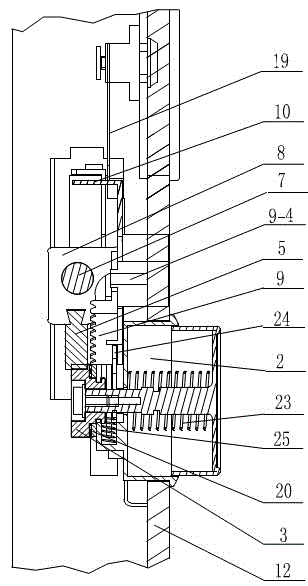

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] The rack is a double-groove rack 9, its section is ∟ shape, two waist holes are arranged on the horizontal plane, and upper and lower limit nails 9-2, 9-4 are respectively inserted in the upper and lower waist holes of the double-slot rack. There is a breach 9-3 in the middle of the two vertical junction surfaces, and helical teeth 9-1 are arranged on the upper surface of the vertical surfaces.

[0014] There is a groove in the middle of the upper surface of the rack seat 1, and the upper and lower limit nails are fixed on the groove. The double-groove rack 9 moves in the groove, and the upper and lower limit nails will not fall out. The rack seat 1 is welded obliquely It is fixed on the door panel 12 on the side of the handle base 2-2, and the inclined installation angle of the rack seat matches the inclination angle of the upper helical tooth 9-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com