Melt filter element for spandex production

A technology of melt filter element and spandex, which is applied in filament forming treatment, textile and papermaking, fiber treatment, etc. It can solve the problem that the pore size uniformity and processing resistance performance are difficult to meet the use requirements, the regeneration process is complicated, and the operator is harmful, etc. problems, achieve better filtering effect, uniform pore size, and easy detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

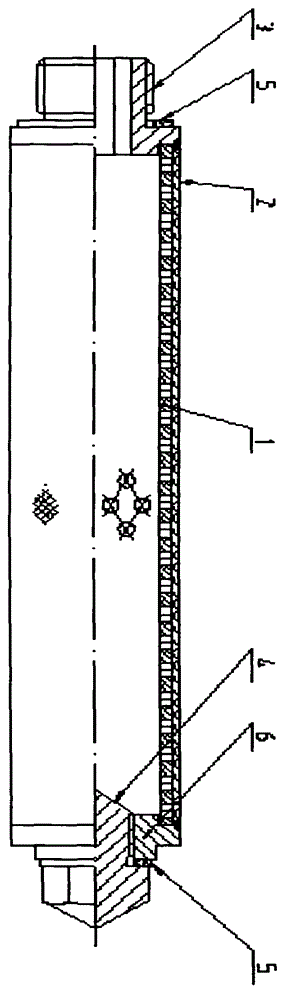

[0029] Such as Figure 1-2 As shown in , a melt filter used in the production of spandex includes a support frame 1, a filter cartridge 2 and a connector.

[0030] Wherein the support frame 1 is made of a stainless steel punched plate, specifically, the stainless steel plate is punched and then rolled into a cylinder, and the two edges are welded together to form a hollow cylinder. It can also be processed by directly punching holes on the steel pipe.

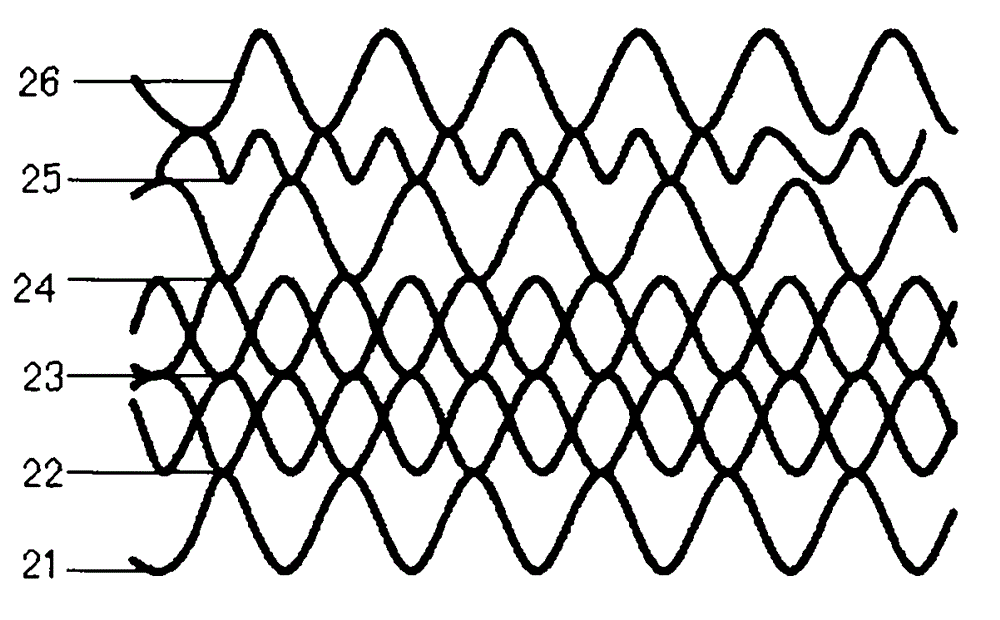

[0031] The filter cartridge 2 is a hollow cylinder made of stainless steel sintered mesh processed by vacuum sintering of multi-layer stainless steel mesh. The stainless steel sintered wire mesh includes at least a five-layer structure of a protective layer 26, a control layer 25, a dispersion layer 24, a skeleton layer 23 and a skeleton layer 22 from outside to inside. More preferably, a diffusion layer 21 is added inside the skeleton layer. The control layer 25 preferably adopts a reverse weaving net, especially a reverse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com