Production method of strong-solvent-resistant thermosetting organic fluorescent pigment

A technology for fluorescent pigments and production methods, applied in luminescent materials, chemical instruments and methods, inks, etc., can solve the problems of synthetic resin with many small molecules, low crosslinking degree, and short time, so as to promote hydroxylation and etherification Reaction, increase molecular cross-linking degree, improve the effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the production method of strong solvent-resistant thermosetting organic fluorescent pigment

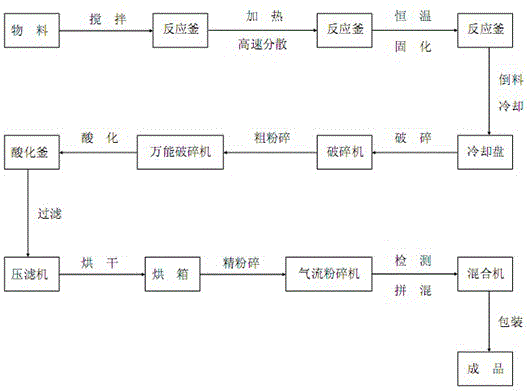

[0031] A kind of production method of strong solvent-resistant thermosetting organic fluorescent pigment, technological process is as follows figure 1 As shown, including: one-time feeding, mixing, high-speed dispersion;

[0032] Put 128 kg of p-toluenesulfonamide, 150 kg of liquid formaldehyde (30%), 40 kg of melamine, 5kg of fluorescent dyes, 0.3kg of liquid caustic soda and 2kg of additives into the reactor, and turn on the stirring for pre-dispersion;

[0033] Open the jacket steam valve and drain valve to raise the temperature of the material to 95°C;

[0034] When the temperature of the material rises to 95°C, empty the steam in the jacket, and keep the temperature of the material in the kettle constant for 100 minutes;

[0035] Heating up, the steam pressure is controlled at 6.0kgf / cm 2 Below, control the temperature of the material to not exceed 1...

Embodiment 2

[0048] Embodiment 2, the production method of strong solvent-resistant thermosetting organic fluorescent pigment

[0049] A method for producing a strong solvent-resistant thermosetting organic fluorescent pigment, comprising: one-time feeding, mixing, and high-speed dispersion;

[0050] Put 120kg of p-toluenesulfonamide, 150kg of liquid formaldehyde (30%), 45kg of melamine, 5kg of fluorescent dye, 0.3kg of liquid caustic soda and 2kg of additives into the reactor, and turn on the stirring for pre-dispersion;

[0051] Open the jacket steam valve and drain valve to raise the temperature of the material to 96°C;

[0052] When the temperature of the material rises to 96°C, empty the steam in the jacket, and keep the temperature of the material in the kettle constant for 100 minutes;

[0053] Heating up, the steam pressure is controlled at 6.0kgf / cm 2 Below, control the temperature of the material to not exceed 130°C, and react until the agitation stops and automatically t...

Embodiment 3

[0066] Embodiment 3, the production method of strong solvent resistant thermosetting organic fluorescent pigment

[0067] A method for producing a strong solvent-resistant thermosetting organic fluorescent pigment, comprising: one-time feeding, mixing, and high-speed dispersion;

[0068] Put 110kg of p-toluenesulfonamide, 150kg of liquid formaldehyde (30%), 51kg of melamine, 5kg of fluorescent dye, 0.3kg of liquid caustic soda and 2kg of additives into the reactor, and turn on the stirring for pre-dispersion;

[0069] Open the jacket steam valve and drain valve to raise the temperature of the material to 98°C;

[0070] When the temperature of the material rises to 98°C, empty the steam in the jacket, and keep the temperature of the material in the kettle constant for 100 minutes;

[0071] Heating up, the steam pressure is controlled at 6.0kgf / cm 2 Below, control the temperature of the material to not exceed 130°C, and react until the agitation stops and automatically t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com