Treatment method for sea water decalcification through equilibrium adsorption of centrifuge

A treatment method and centrifuge technology, applied in seawater treatment, ion exchange water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effects of solving equipment fouling, increasing water production ratio, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

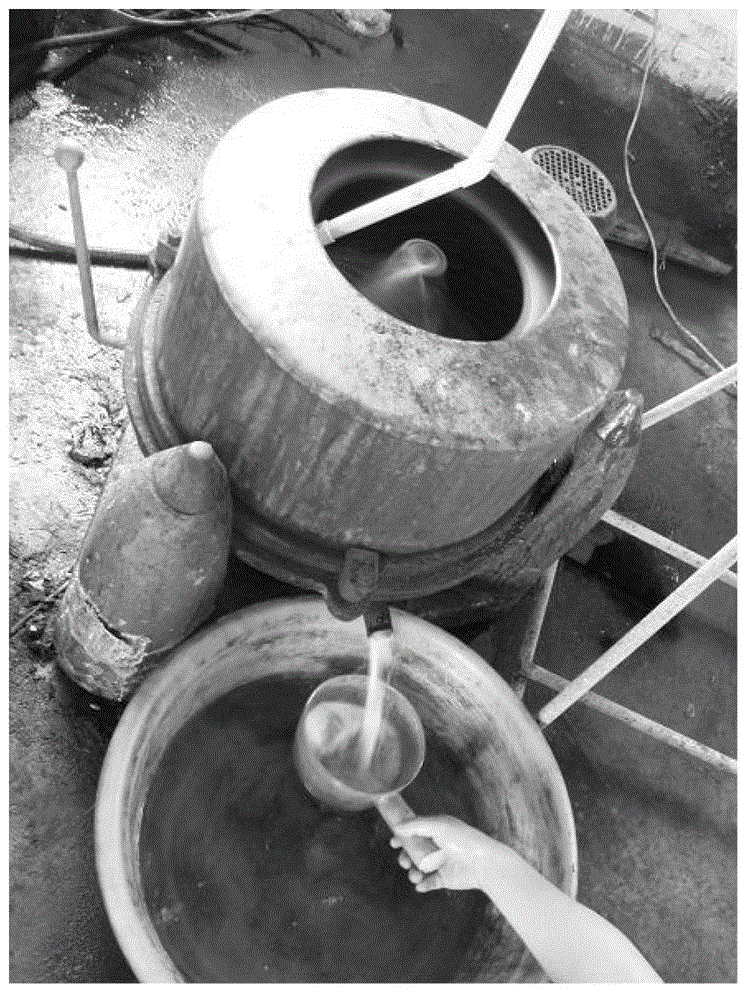

Image

Examples

Embodiment 1

[0037] 1. Centrifuge seawater decalcification test

[0038] A centrifuge equilibrium adsorption seawater decalcification processing method, the steps are as follows:

[0039] (1) Mix 12 kg of adsorption material with 30 kg of water to make a slurry;

[0040] (2) Let the slurry in step (1) stand for 5 minutes, settle the material, and then pour the upper layer of clear water to obtain the lower layer material-water mixture;

[0041] (3) The mixture is controlled by the pump to feed at a speed of 0.8 m 3 / h enters the centrifuge, centrifuges through the filter cake and flows out from the water outlet, and the obtained filtrate is decalcified seawater.

Embodiment 2

[0043] 1. Centrifuge seawater decalcification test

[0044] A centrifuge equilibrium adsorption seawater decalcification processing method, the steps are as follows:

[0045] (1) Mix 12 kg of adsorption material with 24 kg of water to make a slurry;

[0046] (2) Set aside the slurry in step (1) for 4 minutes to settle the material, then pour the upper layer of clear water to obtain the lower layer material-water mixture;

[0047] (3) The mixture is controlled by a pump to feed at a speed of 0.6 m 3 / h enters the centrifuge, centrifuges through the filter cake and flows out from the water outlet, and the obtained filtrate is decalcified seawater.

Embodiment 3

[0049] 1. Centrifuge seawater decalcification test

[0050] A centrifuge equilibrium adsorption seawater decalcification processing method, the steps are as follows:

[0051] (1) Mix 12 kg of adsorption material with 36 kg of water to make a slurry;

[0052] (2) Set aside the slurry in step (1) for 6 minutes to settle the material, then pour the upper layer of clear water to obtain the lower layer material-water mixture;

[0053] (3) The mixture is controlled by a pump to feed at a speed of 1 m 3 / h enters the centrifuge, centrifuges through the filter cake and flows out from the water outlet, and the obtained filtrate is decalcified seawater.

[0054] Result detection and data analysis:

[0055]After inspecting the seawater in a container with a depth (height) of 1.2 meters, the material was stirred for 5 minutes, and it was found that the material has basically sunk to the bottom, and most (> 85% or even more than 90%) of the seawater can be removed by pouring. Pour off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com