Casting polypropylene film for coating metal substrate and preparation method thereof

A technology for casting polypropylene and metal substrates, which is applied in the direction of metal layered products, chemical instruments and methods, coatings, etc., can solve the problems of low printing strength, surface film breakage, and high equipment requirements, and achieve a simple and scientific preparation method , small molecular orientation, high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

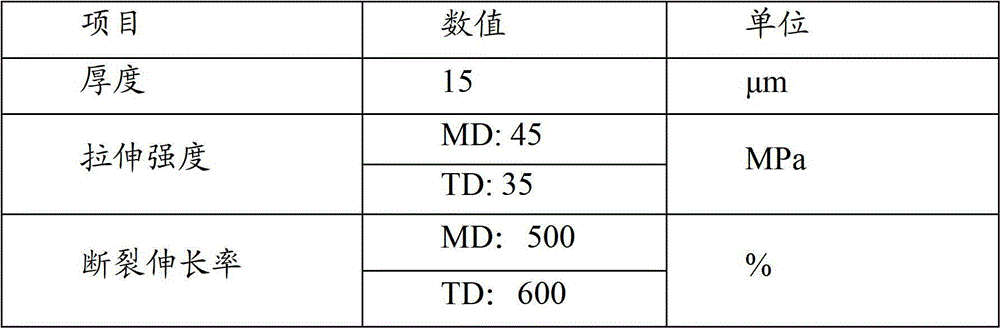

Embodiment 1

[0028] Raw material formula of cast polypropylene film:

[0029] Polypropylene modified resin: maleic anhydride modified polypropylene resin (the molar content of maleic anhydride in the modified polypropylene resin is 5%), intrinsic viscosity 0.7dL / g;

[0030] Polypropylene resin: polypropylene chips, intrinsic viscosity 0.7dL / g.

[0031] Process method:

[0032] (1) Put the above-mentioned polypropylene modified resin and polypropylene chips into different barrels, melt them through different screw extruders, and then pass through a multi-channel co-extrusion head (for example, a co-extrusion with three channels The melt of polypropylene modified resin and polypropylene resin is extruded from the die of the extruder head), the temperature of the screw extruder and the die is controlled between 190-230°C, and the temperature of the barrel can be gradually increased from 180°C Raise to 320°C;

[0033] (2) The melt is cast by casting rolls, and the cooled film primary produc...

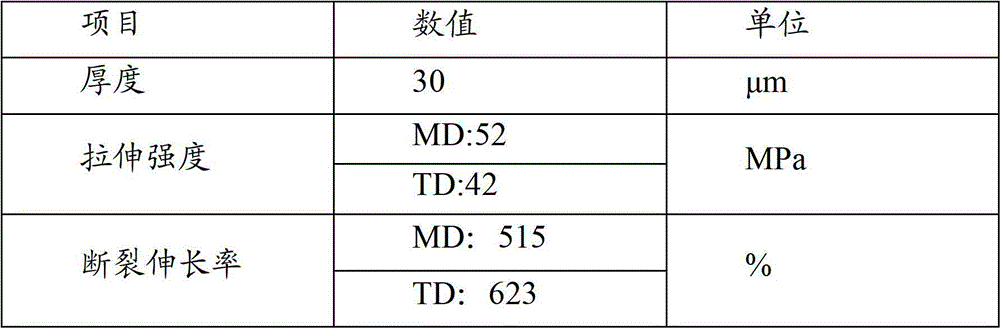

Embodiment 2

[0044] Raw material formula of cast polypropylene film:

[0045] Polypropylene modified resin: maleic anhydride modified polypropylene resin (the molar content of maleic anhydride in the modified polypropylene resin is 12%), intrinsic viscosity 0.8dL / g;

[0046] Polypropylene resin: polypropylene chips, intrinsic viscosity 0.8dL / g.

[0047] Process method:

[0048] (1) Put the above-mentioned maleic anhydride-modified polypropylene resin and polypropylene chips into different barrels, melt them through different screw extruders, and then extrude polypropylene through the die of the multi-channel co-extrusion head The melt of modified resin and polypropylene resin, the temperature of the screw extruder and the die is controlled between 190-230°C, and the temperature of the barrel can be gradually increased from 180°C to 320°C;

[0049] (2) The melt is cast by casting rolls, and the cooled film primary product is obtained after the cooling rolls are cooled. The temperature of ...

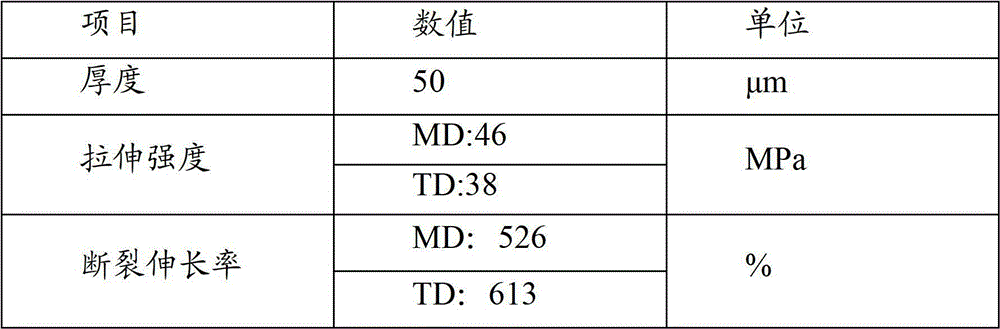

Embodiment 3

[0054] Raw material formula of cast polypropylene film:

[0055] Polypropylene modified resin layer: maleic anhydride modified polypropylene resin (the molar content of maleic anhydride in the modified polypropylene resin is 20%), intrinsic viscosity 0.85dL / g;

[0056] Polypropylene resin: polypropylene chips, intrinsic viscosity 0.85dL / g

[0057] Process method: (1) Put the above-mentioned maleic anhydride modified polypropylene resin and polypropylene chips into different barrels, melt them through different screw extruders, and then extrude them through the die mouth of the multi-channel co-extrusion head The melt of polypropylene modified resin and polypropylene resin is produced, the temperature of the screw extruder and the die is controlled between 190-230°C, and the temperature of the barrel can be gradually increased from 180°C to 320°C;

[0058] (2) The melt is cast by casting rolls, and the cooled film primary product is obtained after the cooling rolls are cooled....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com