Jaw bone density measuring device and jaw bone density measuring method for oral computed tomography (CT) system

A measuring device and dental technology, applied in the field of medical devices, can solve problems such as incomplete reflection of bone density, incapability of quantitative analysis of bone density, increased radiation dose of patients, etc., and achieve low maintenance costs, convenient application, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

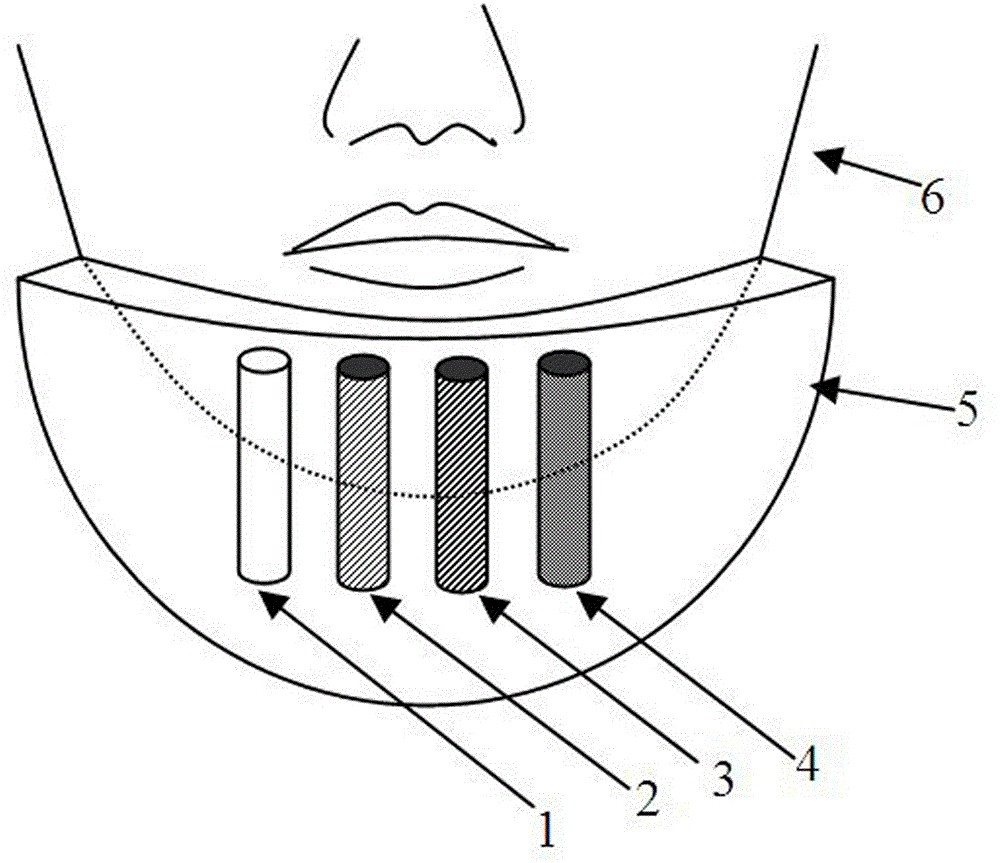

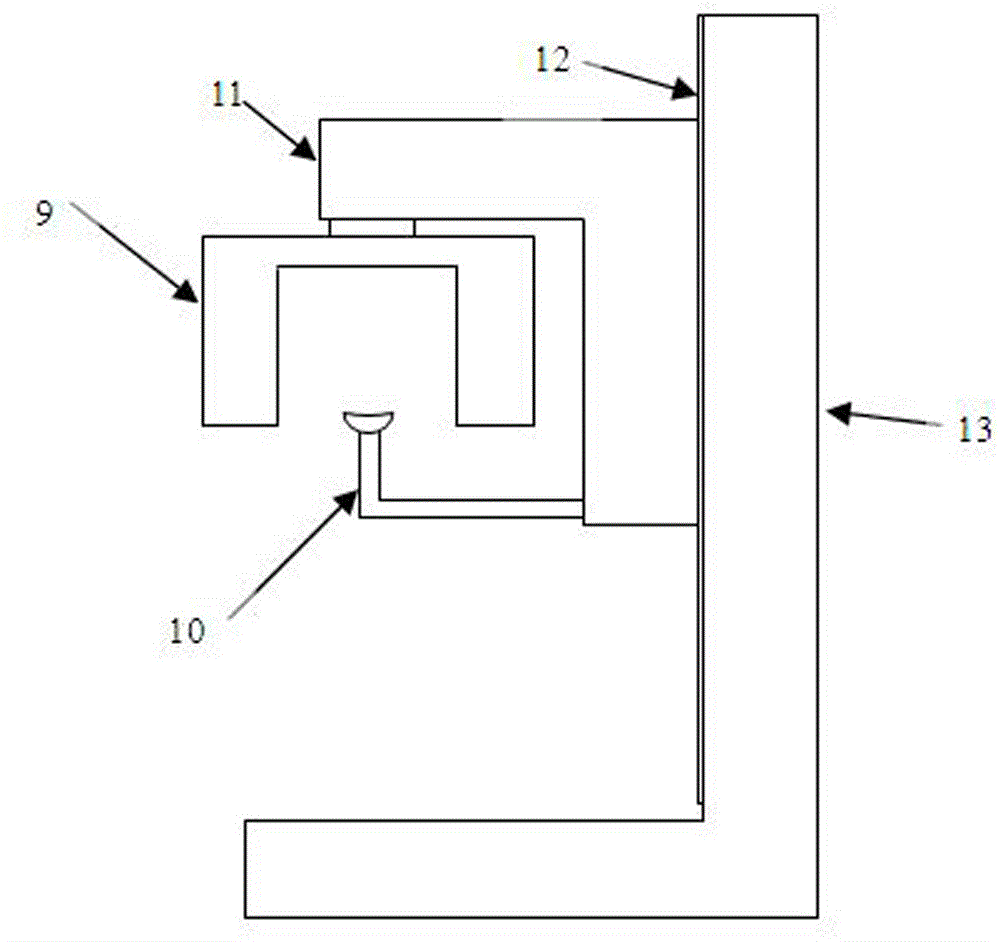

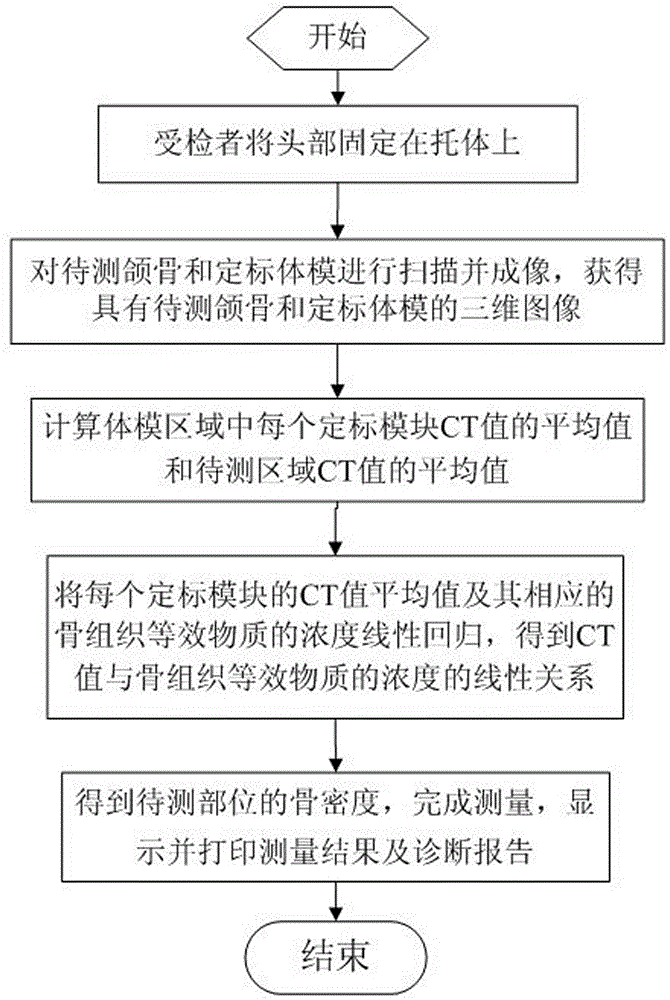

[0049] Such as figure 1 As shown, in this embodiment, there are 4 calibration modules, and the bone tissue equivalent substance selection and bone mineral Ca in each calibration module 10 (PO 4 ) 6 (OH) 2 The atomic number 16.62 is similar to the atomic number 15.83 K 2 HPO 4 As a bone tissue equivalent, formulate K 2 HPO 4 Concentrations were 0 mg / cm 3 , 100 mg / cm 3 , 200 mg / cm 3 , 300 mg / cm 3 K 2 HPO 4 The aqueous solution is sealed and filled in four calibration modules 1, 2, 3, and 4 respectively. In this embodiment, a liquid calibration module that meets the above conditions is used, and a solid calibration module can also be used under other specific implementation conditions.

[0050] Due to the high density of the teeth and jaws themselves, the dynamic range of their CT values in the CT image is large, so in this embodiment, the K of the mixture in each calibration phantom 2 HPO 4 The concentration selection span is large in order to obtain accurate me...

Embodiment 2

[0063] In this embodiment, there are 3 calibration modules, and the bone tissue equivalent material selection and bone mineral Ca in each calibration module 10 (PO 4 ) 6 (OH) 2 The atomic number 16.62 is similar to the atomic number 15.83 K 2 HPO 4 As a bone tissue equivalent, formulate K 2 HPO 4 Concentrations were 50 mg / cm 3 , 150 mg / cm 3 , 250 mg / cm 3 K 2 HPO 4 The aqueous solution is sealed and filled in the four calibration modules 1, 2, and 3 respectively. In this embodiment, a liquid calibration module that meets the above conditions is used, and a solid calibration module can also be used under other specific implementation conditions.

[0064]The method for measuring jaw bone density using the device for measuring jaw bone density used in an oral CT system is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com