High-voltage gas circuit breaker

A high-voltage circuit breaker, high-voltage gas technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of high processing cost, increase airflow resistance, erosion, etc., to improve airflow blocking ability, The effect of improving airflow and long electrical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

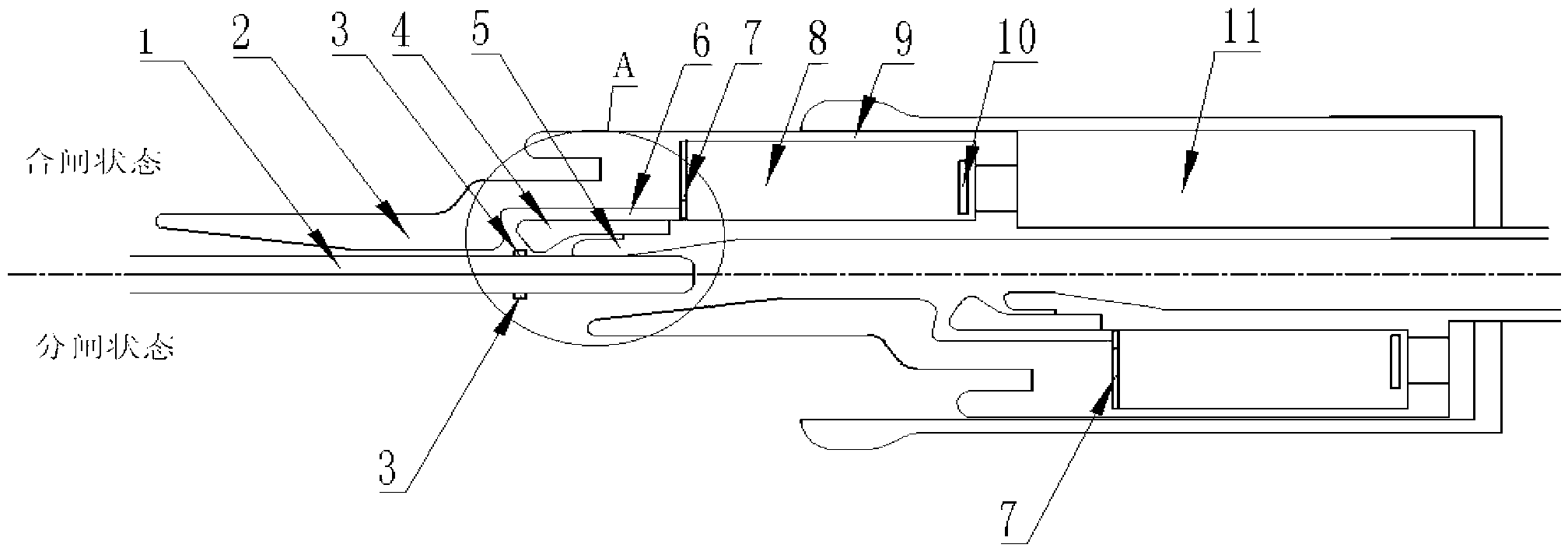

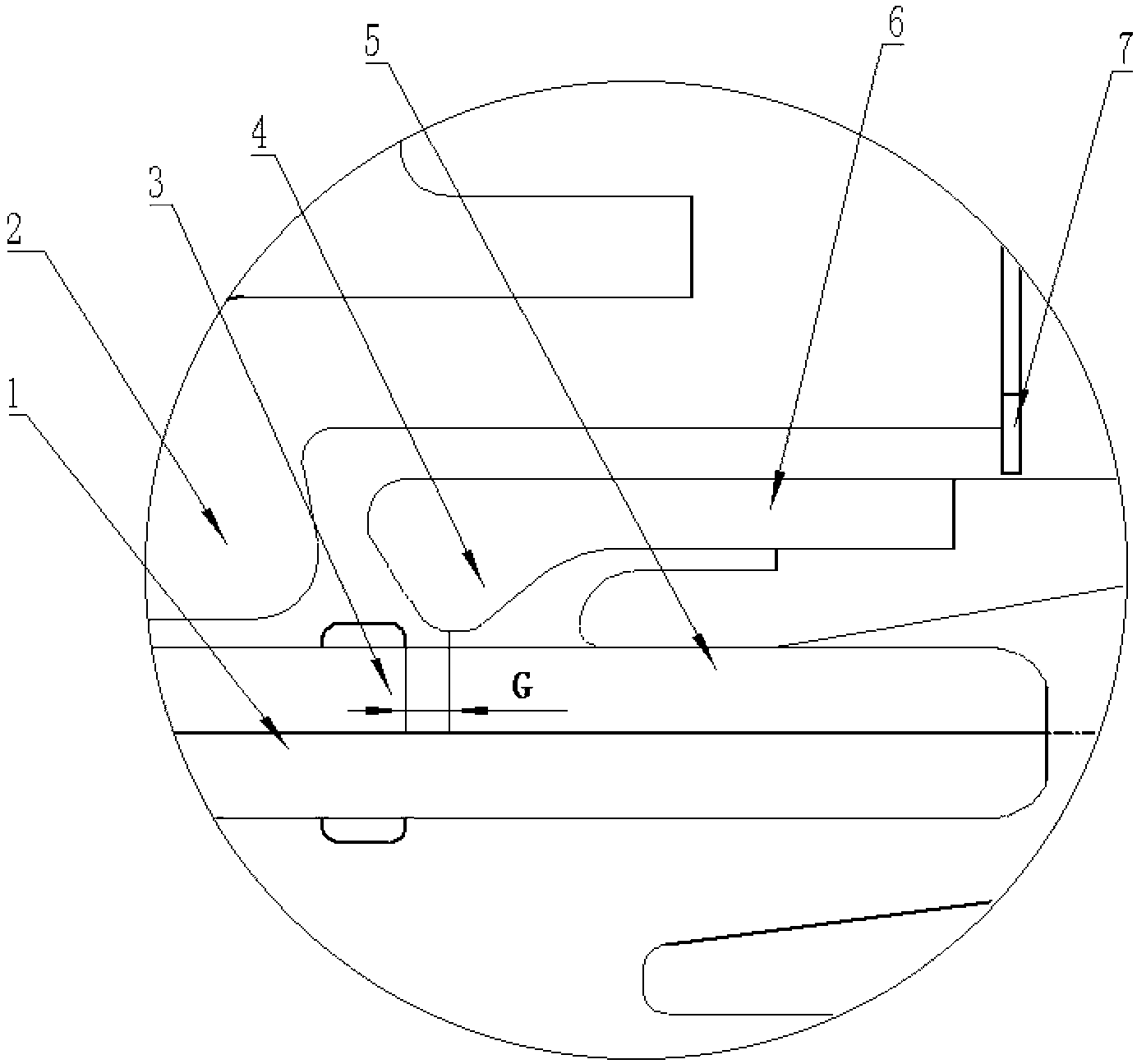

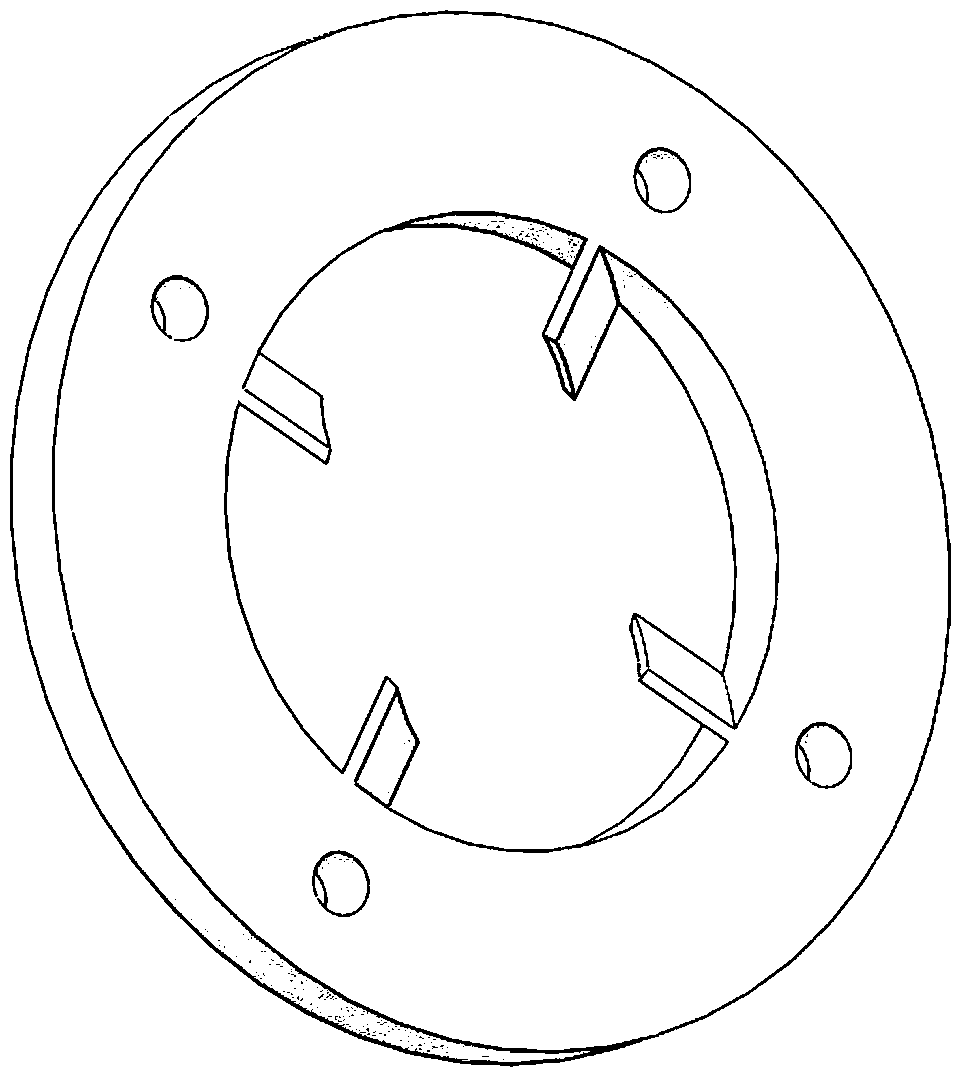

[0023] like figure 1 As shown, this embodiment includes: static arc contact 1, main nozzle 2, auxiliary nozzle 4, moving arc contact 5, blocking ring 3, vortex generator 7 and piston 9, wherein: main nozzle 2, auxiliary nozzle 4, The moving arc contact 5 and the vortex generator 7 are respectively fixedly connected with the piston 9 to form the moving part of the arc extinguishing chamber and face the static arc contact 1. The moving part of the arc extinguishing chamber is driven by the circuit breaker mechanism to realize the breaking process. The main nozzle 2 A heating channel 6 is formed between the auxiliary nozzle 4 .

[0024] The inner diameter range of the throat of the main nozzle 2 is 20mm-80mm; the inner diameter of the throat of the main nozzle 2 is preferably 36mm,

[0025] The outer diameter range of the static arc contact 1 is 16mm-76mm; preferably 26mm,

[0026] The gap between the static arc contact 1 and the throat inner wall of the main nozzle 2 is 5mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com