Vertical spiral-type buried pipe construction method for GRHP (ground source heat pump)

A construction method and technology of ground source heat pump, which are applied in infrastructure engineering, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. The problems of shallow pipe burial depth, etc., achieve the effect of small footprint, reduced construction cost and land resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

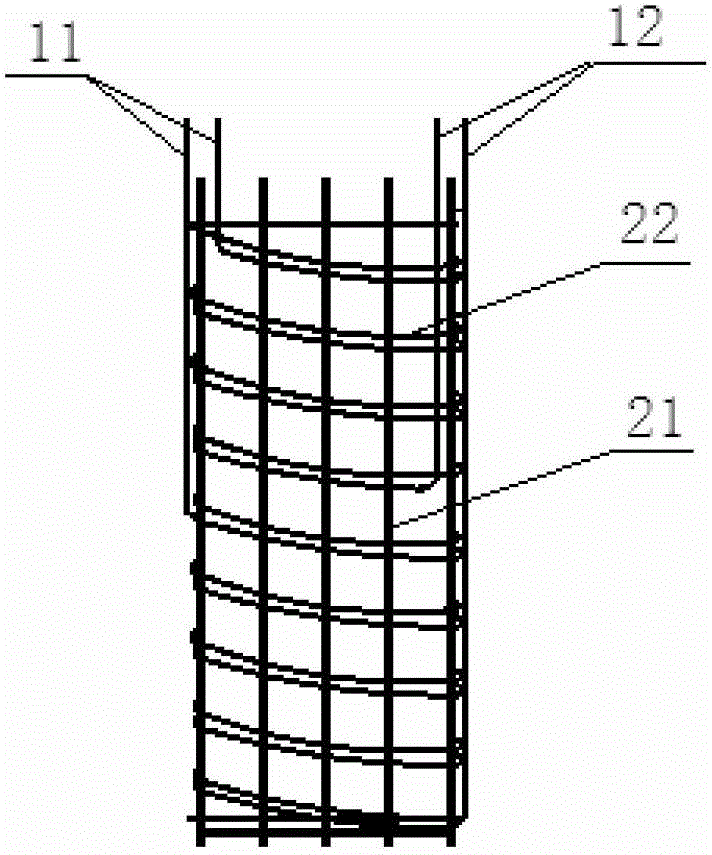

[0032] The construction method of the vertical spiral buried pipe of the ground source heat pump provided in this embodiment includes the following steps:

[0033] (1) Repairing structural piles: Check whether the structural piles of the building itself meet the requirements: the allowable deviation of the diameter of the structural piles is +10mm, and the allowable deviation of the verticality of the structural piles is less than 3‰ of the length of the hole piles. Repair the hole piles that do not meet the requirements. Meet the requirements. Specifically, in this project, the depth or diameter of 45 structural piles did not meet the requirements for buried pipes, so they were discarded; the other 125 structural piles can be used as heat exchange piles, so the 125 structural piles are also used as heat exchange piles. Used to bury PE coils. Of the 125 structural piles and heat exchange piles, the verticality of 13 structural piles and heat exchange piles did not meet the re...

Embodiment 2

[0044] The construction method of the vertical spiral buried pipe of the ground source heat pump provided in this embodiment includes the following steps:

[0045] (1) Excavate heat exchange piles: Excavate heat exchange piles according to design specifications, and the diameter of heat exchange piles is 2 meters. The heat exchange pile excavation technology is very mature and will not be repeated here.

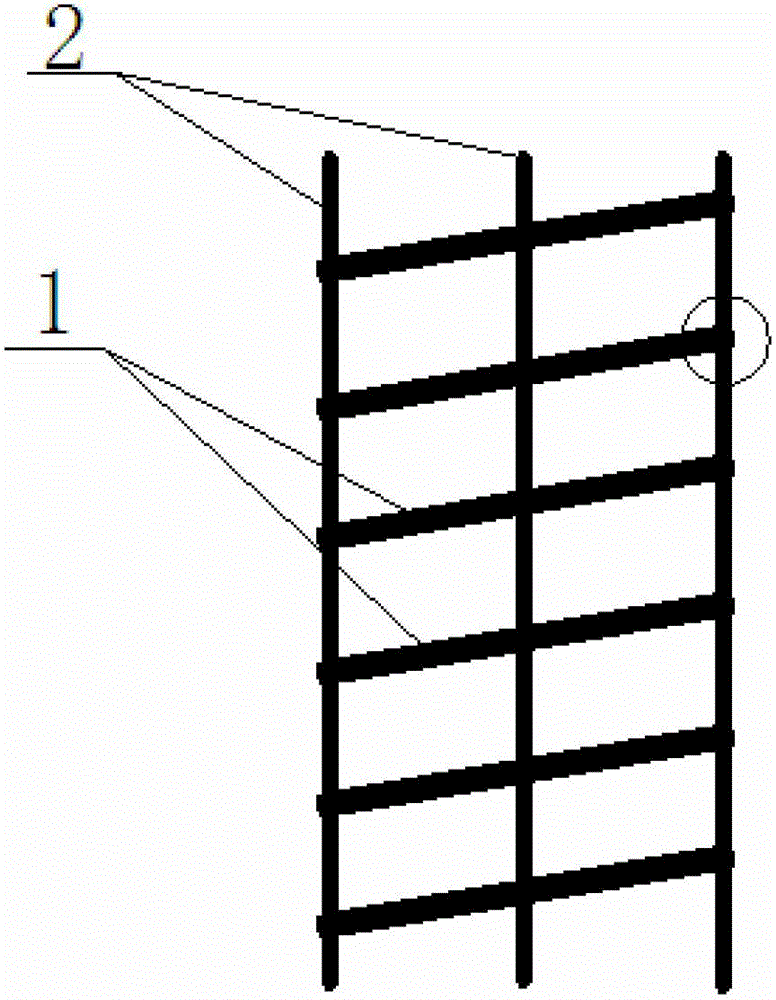

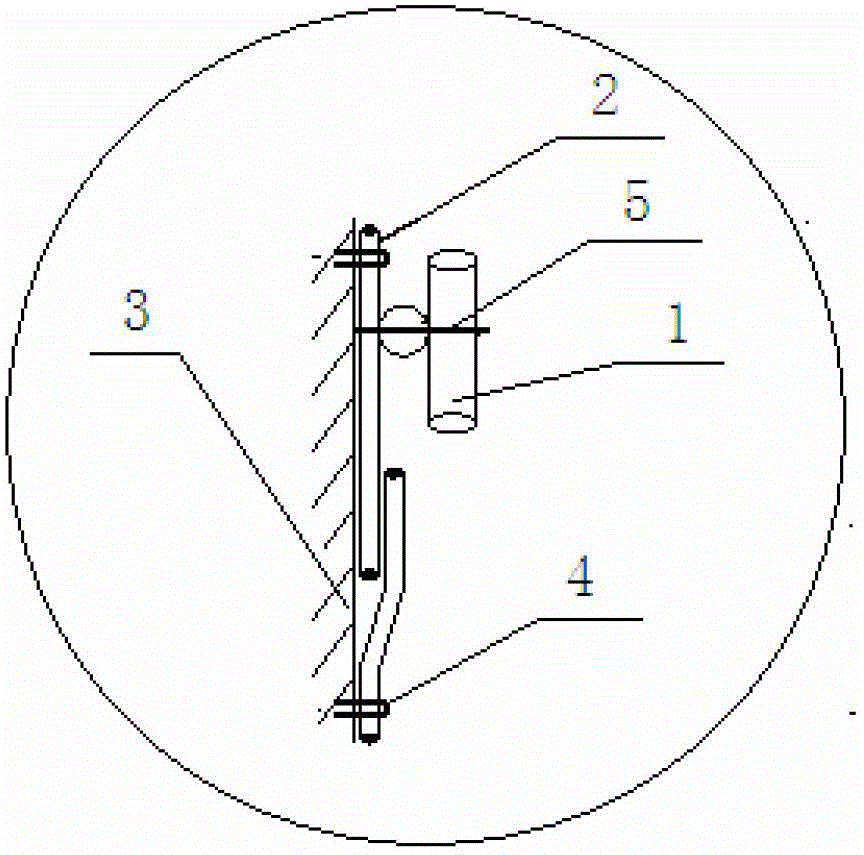

[0046] (2) Make steel bar support: bury Φ12 steel bars 2 around the retaining wall of the hole pile as the steel bar support. The spacing of the clamps 4 is not greater than 2000mm. In the process of embedding Φ12 steel bar 2, if the heat exchange pile is deep and a Φ12 steel bar 2 cannot extend from the bottom of the pile to the pile mouth, it should be connected by lap joint, and the lap length should not be less than 15 times the diameter of Φ12 steel bar 2 times, in the same section, the overlapping area of Φ12 steel bars should not exceed 50%, refer to image 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com