Treatment method of equilibrium adsorption seawater decalcification of plate-and-frame filter press

The technology of a plate and frame filter press and a treatment method is applied in seawater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effects of saving production costs, fast filtration, and sufficient response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

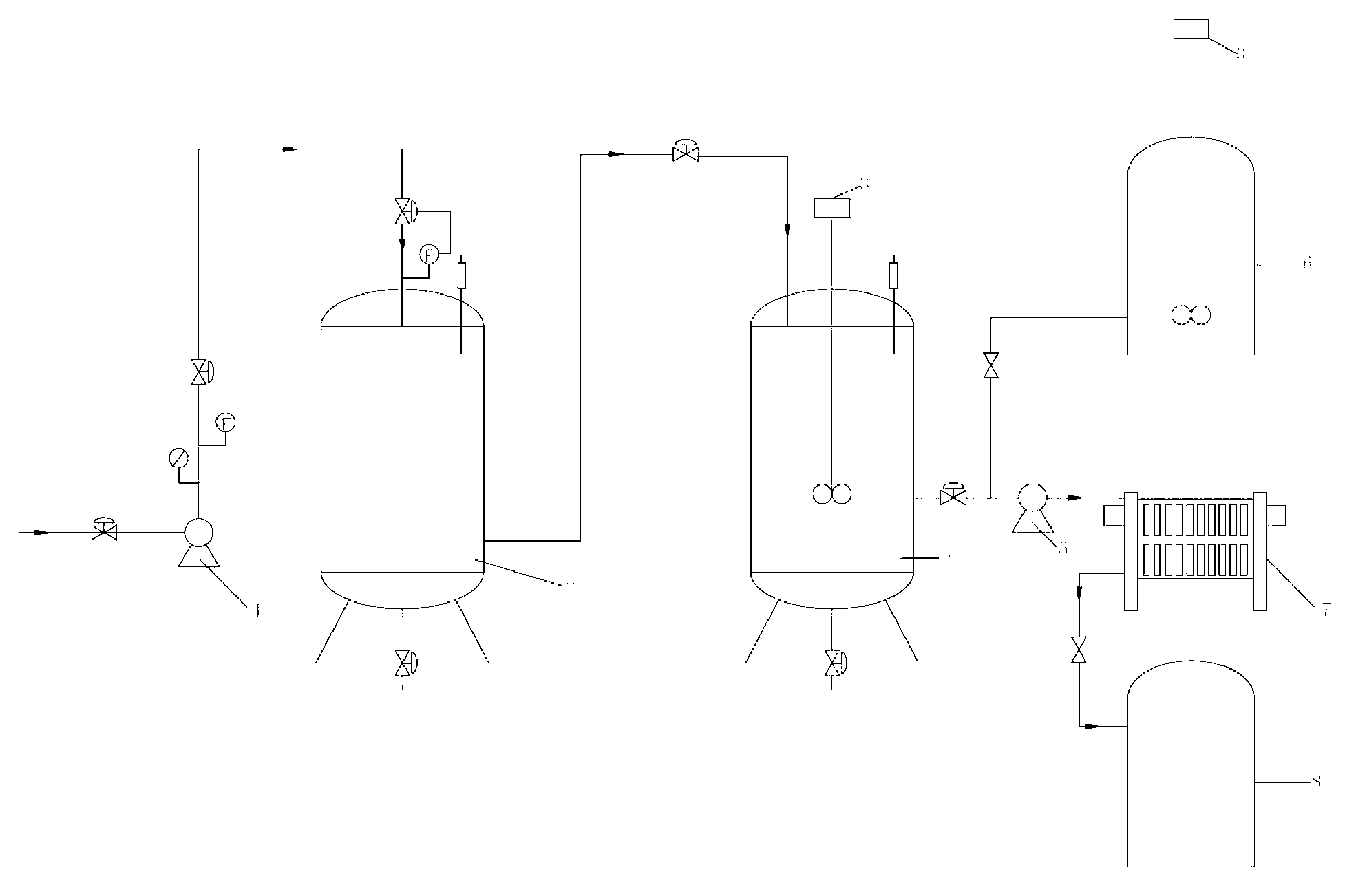

Image

Examples

Embodiment 1

[0038] A treatment method for balanced adsorption of seawater decalcification by a plate and frame filter press, the specific steps are as follows:

[0039] (1) Disperse 130 kg of powdered adsorption material with 260 kg of tap water to make a slurry;

[0040] (2) Add seawater to the slurry adsorbent material in step (1), the adsorbent material is to Ca 2+ The exchange capacity is 2mol-3mol / kg, stirring for 1 to 2 minutes to form a mixed slurry;

[0041] (3) Inject the mixed slurry into the plate-and-frame filter press, the adsorbent material remains in the filter press, and the obtained filtrate is decalcified seawater.

Embodiment 2

[0043] A treatment method for balanced adsorption of seawater decalcification by a plate and frame filter press, the specific steps are as follows:

[0044] (1) Disperse 260 kg of powdered adsorption material with 260 kg of tap water to make a slurry;

[0045] (2) Add seawater to the slurry adsorbent material in step (1), the adsorbent material is to Ca 2+ The exchange capacity is 2mol-3mol / kg, stirring for 10 minutes to form a mixed slurry;

[0046] (3) Inject the mixed slurry into the plate-and-frame filter press, the adsorbent material remains in the filter press, and the obtained filtrate is decalcified seawater.

Embodiment 3

[0048] A treatment method for balanced adsorption of seawater decalcification by a plate and frame filter press, the specific steps are as follows:

[0049] (1) Disperse 180 kg of powdered adsorption material with 260 kg of tap water to make a slurry;

[0050] (2) Add seawater to the slurry adsorbent material in step (1), the adsorbent material is to Ca 2+ The exchange capacity is 2mol-3mol / kg, stirring for 5 minutes to form a mixed slurry;

[0051](3) Inject the mixed slurry into the plate-and-frame filter press, the adsorbent material remains in the filter press, and the obtained filtrate is decalcified seawater.

[0052] Decalcification experiment design and data analysis:

[0053] 1. Data analysis of laboratory test results

[0054] Our previous work showed that ion exchange can be completed in less than a minute under well-stirred and well-mixed equilibrium conditions. In this experiment, we used the method of adding material powder and stirring in seawater for 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com