Rotary grinding operating platform

A worktable and rotary table technology, applied in the directions of grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity, low work efficiency, poor operation, etc., to ensure product quality, reduce labor intensity, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

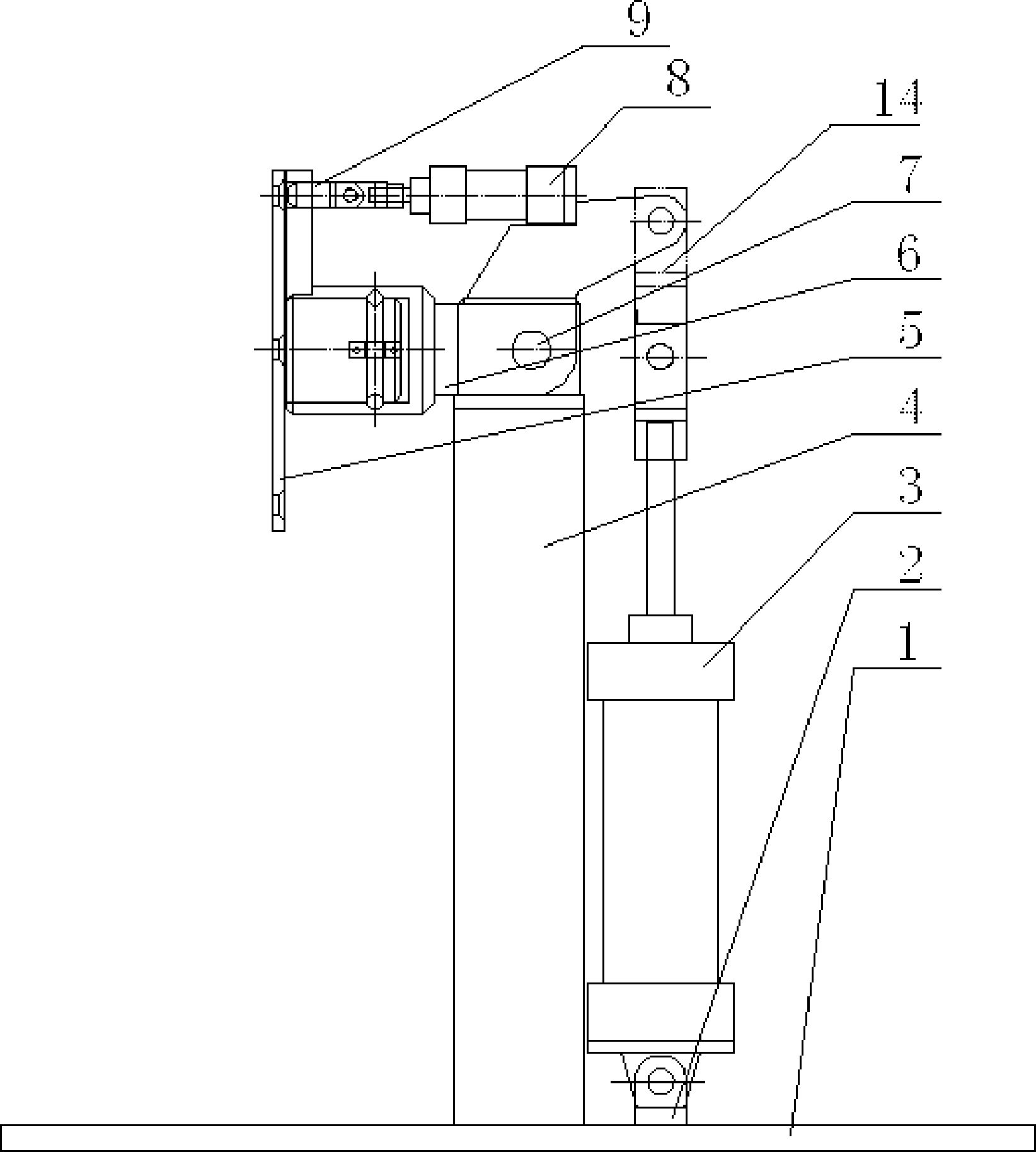

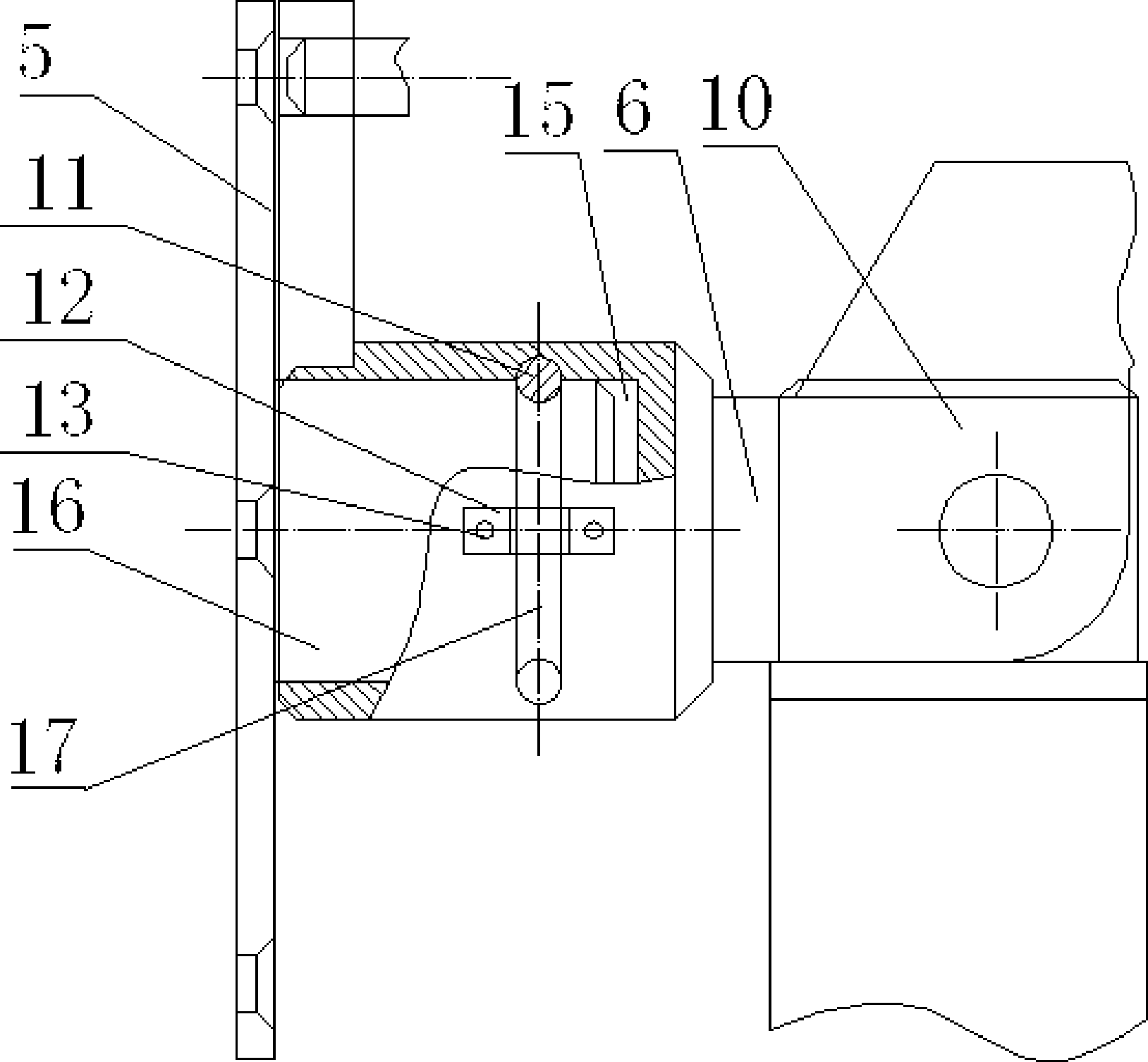

[0017] Such as figure 1 , figure 2 The rotary grinding workbench shown includes a base 1; the bottom end of the column 4 is fixed on the base 1, and the top of the column 4 has a U-shaped fork seat 10 for installing the rotating support 6, and the rotating support 6 is in the shape of "Z". ", the middle part of the rotating support 6 is provided with a hinge installation hole, which is hinged on the U-shaped fork seat 10 through the hinge shaft 7, and the cylinder base of the first cylinder 3 is fixed on the base 1 through the hinge ear 2 and the hinge The shaft is hinged to the base 1, the piston rod of the first cylinder 3 is connected to the first end of the connecting rod 14, the second end of the connecting rod 14 is hinged to the second end of the swivel support 6, and the expansion and contraction of the piston rod of the first cylinder 3 , the position of the rotary table 5 can be adjusted between the vertical direction and the horizontal direction, the first end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com