Heat-preserving furnace for magnesium alloy die casting

A technology of holding furnace and magnesium alloy, applied in the field of industrial furnace, can solve the problem of unguaranteed product quality of die casting products, and achieve the effect of stable quality and temperature control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

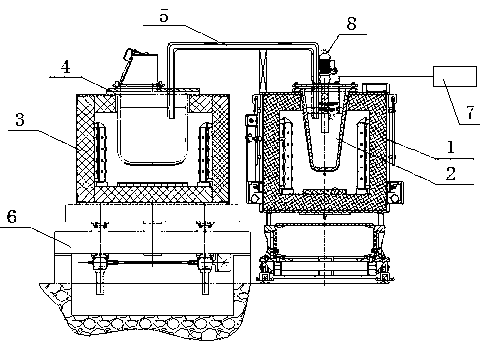

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] Such as figure 1 As shown, the holding furnace for magnesium alloy die-casting of the present invention includes a holding furnace body 1 with a first crucible 2 inside, and the holding furnace for magnesium alloy die-casting also includes an electric heating furnace 3, and a second crucible is arranged inside the electric heating furnace 3 4. The first crucible 2 and the second crucible 4 are connected through a siphon 5 . A temperature control device is provided in the siphon tube 5 to ensure that the temperature of the magnesium alloy liquid passing through the siphon tube does not change; a casting pump 8 is provided on the holding furnace body 1 to transfer the magnesium alloy liquid into the barrel of the die-casting machine; the electric heating furnace 3 There is a worm gear lifter 6 under it; in the first crucible 2 in the holding furnace body 1, a liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com