Packaging structure without external pin

A technology of packaging structure and external pins, which is applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of excessively long hanging parts of pins, increased cost, shaking and deformation, and avoid electrical performance The effect of reducing, shortening length and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

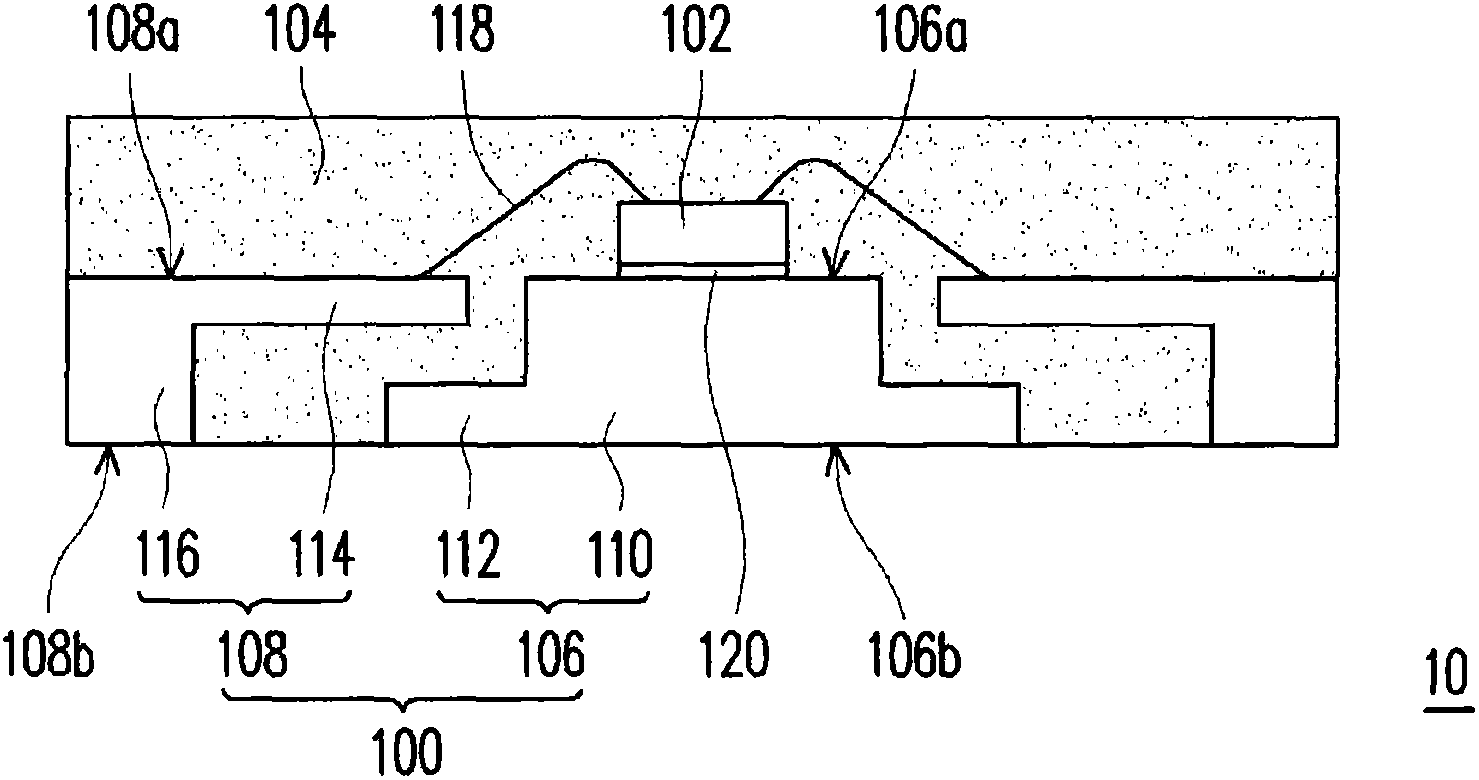

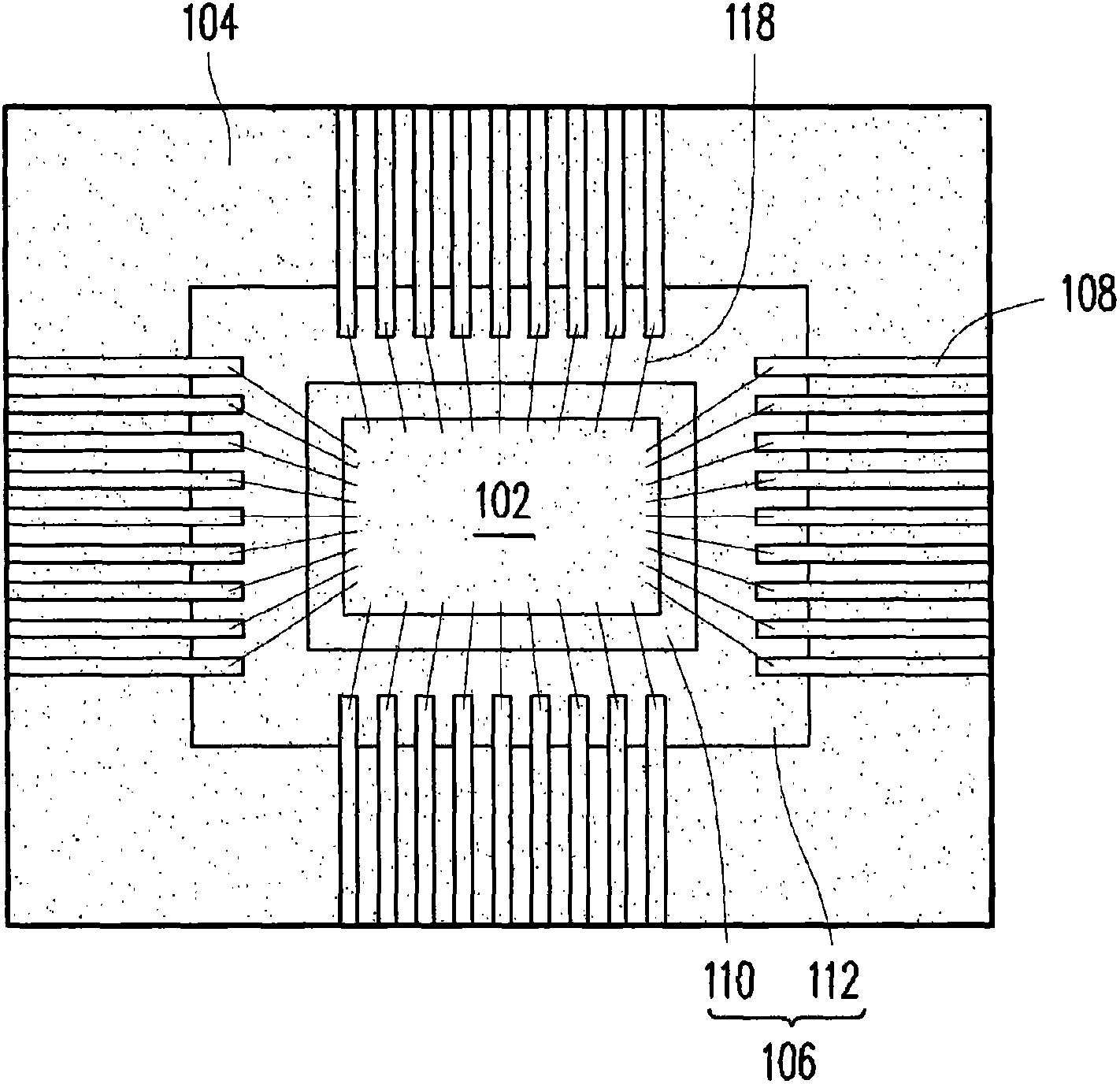

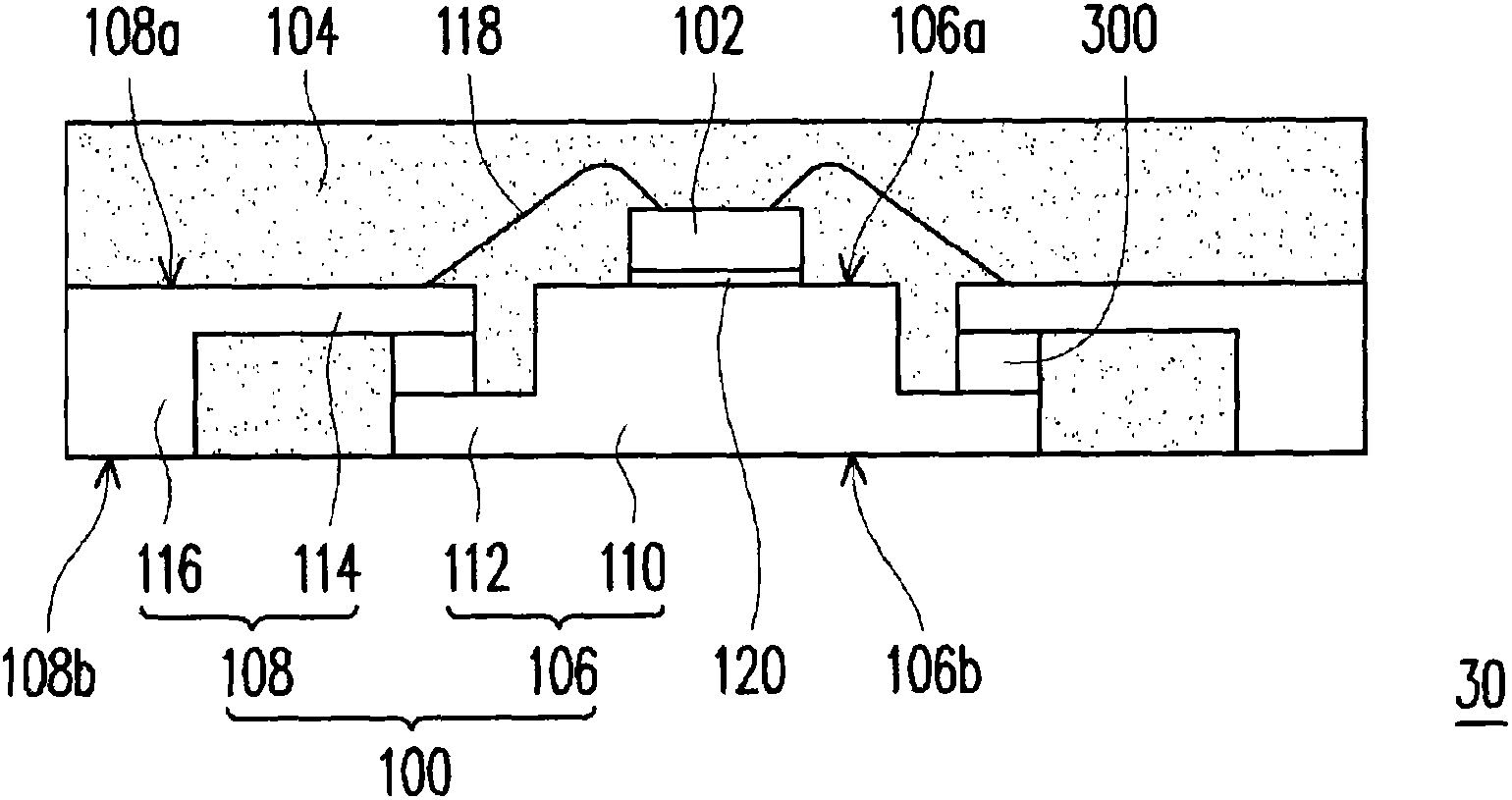

[0018] figure 1 It is a schematic cross-sectional view of a leadless package structure according to an embodiment of the present invention. figure 2 for figure 1 The schematic diagram of the top view of the package structure without external pins. exist figure 2 In , the number of pins is only for illustration, and is not intended to limit the present invention. Please refer to figure 1 and figure 2 , the leadless package structure 10 of this embodiment includes a lead frame 100 , a chip 102 and an encapsulant 104 . The lead frame 100 includes a die paddle 106 and a plurality of pins 108 . The die paddle 106 has a top surface 106a and a bottom surface 106b. In addition, the die holder 106 includes a die bonding portion 110 and a peripheral portion 112 . The peripheral portion 112 connects to and surrounds the die bonding portion 110 . The chip bonding portion 110 is used for disposing the chip 102 thereon.

[0019] In this embodiment, the top surface 106 a of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com