Integrated thin film temperature heat flow compound sensor and preparation method thereof

A composite sensor, thin film temperature technology, applied in thermometers, calorimeters, thermometers using electrical/magnetic components directly sensitive to heat, etc., can solve problems such as simultaneous measurement, and achieve the effect of improving processing workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

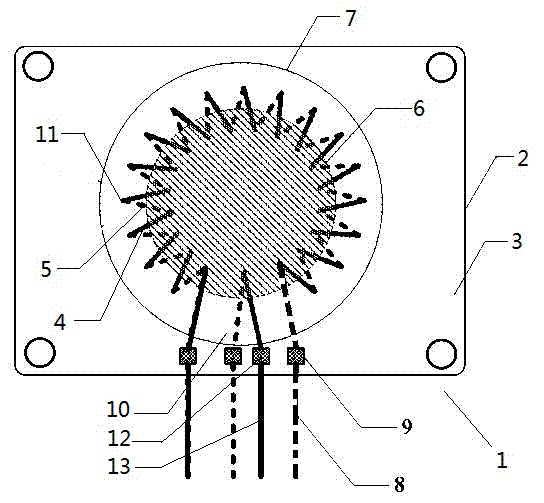

[0035] see figure 1 , the integrated thin film temperature and heat flow composite sensor 1 includes a substrate 2, a transition layer 3 disposed on the substrate 2, and a thin film thermocouple array disposed on the transition layer 3; the thin film thermocouple array consists of an independent thin film The thermocouple 10 is composed of two or more thin-film thermocouples 10 connected in series through an external junction 11. The thin-film thermocouple 10 includes an A electrode 4 and a B electrode 5; the junction of the A electrode 4 and the B electrode 5 is provided with a thick thermal barrier layer 6; a thin thermal barrier layer 7 is provided on the external junction 11 in the thin film thermocouple array and on the free end electrode of the independent thin film thermocouple 10; The pads 12 are connected to the respective corresponding A compensation wires 13, and the two external ends of the two or more series-connected thin film thermocouples 10 are respectively co...

Embodiment 2

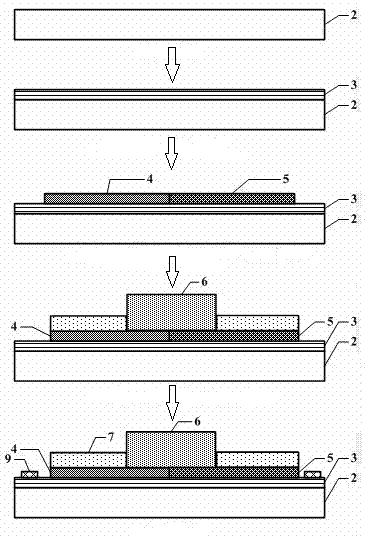

[0039] see figure 2 , the preparation method of the integrated film temperature heat flow composite sensor comprises the following steps:

[0040] (1) For Al with a diameter of 50mm to 150mm and a thickness of 0.5mm to 1mm 2 o 3 The substrate is cleaned to remove oil and impurities on the polished surface of the substrate;

[0041] (2) Set the substrate and the stainless steel mask of the R-type PtRh13-Pt thermocouple PtRh13 electrode together, and clamp it with a stainless steel fixture and put it on the planet carrier of the ion beam sputtering coating machine;

[0042] (3) Deposit Ta with a thickness of 0.05 μm to 0.1 μm by ion beam sputtering 2 o 5 Transition film and PtRh13 thermocouple thin film of 0.1 μm ~ 0.2 μm, remove the stainless steel mask;

[0043] (4) Set the substrate and the stainless steel mask of the R-type PtRh13-Pt thermocouple Pt electrode together, and clamp it with a stainless steel fixture and put it on the planet carrier of the ion beam sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com