Flexible shoulder joint motion sensor and measurement method thereof

A motion sensor and shoulder joint technology, applied in the field of sensors, can solve the problems of insufficient detection accuracy, inability to meet the needs of real-time control of shoulder movement, and lack of real-time performance of the inclination sensor, and achieve a simple fixation method, low power consumption, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

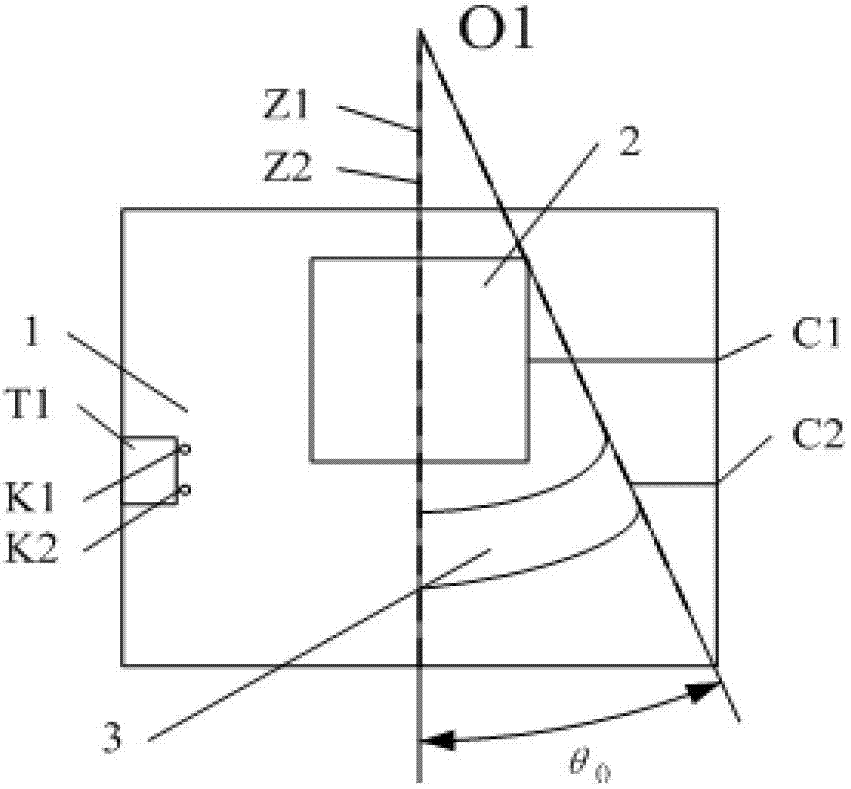

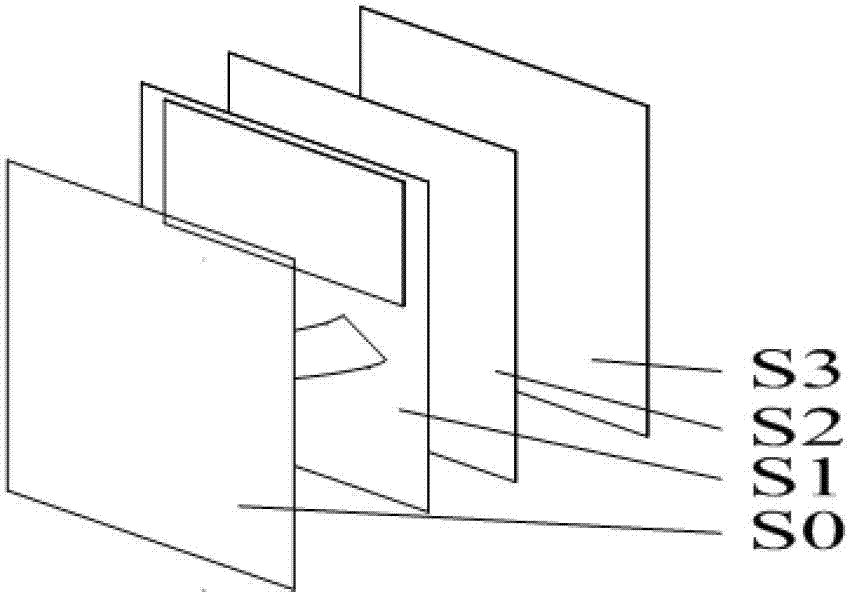

[0037] As shown in Figures 1 and 2, the sensor includes two identical sensing pole pieces, each sensing pole piece is a four-layer laminated structure, and the first layer is the first insulating layer S 0 , constitutes the first layer of capacitor dielectric, the first insulating layer S 0 Below is the capacitive plate layer S 1 , capacitor plate layer S 1 Below is the second insulating layer S 2 , the second insulating layer S 2 Below is the electrostatic shielding layer S 3 . Second insulating layer S 2 Constitute the conductive area and the shielding layer S 3 The capacitive dielectric, electrostatic shielding layer S 3 Effective shielding of static electricity on the human body is achieved through grounding. The capacitive plate layer includes a rectangular flexible substrate 1. On one surface of the rectangular flexible substrate 1, a rectangular conductive area 2 and an incomplete circular conductive area 3 (which can be processed by microelectronics technology)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com