Deep hole caving backfilling stoping method for artificially freezing stope roof

A filling mining method and artificial freezing technology, which is applied in ground mining, underground mining, special mining, etc., can solve the problems of restricting the use of high-efficiency mining methods, affecting the production capacity of ore blocks, and high mining and filling costs, so as to reduce mining costs , Large production capacity, the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

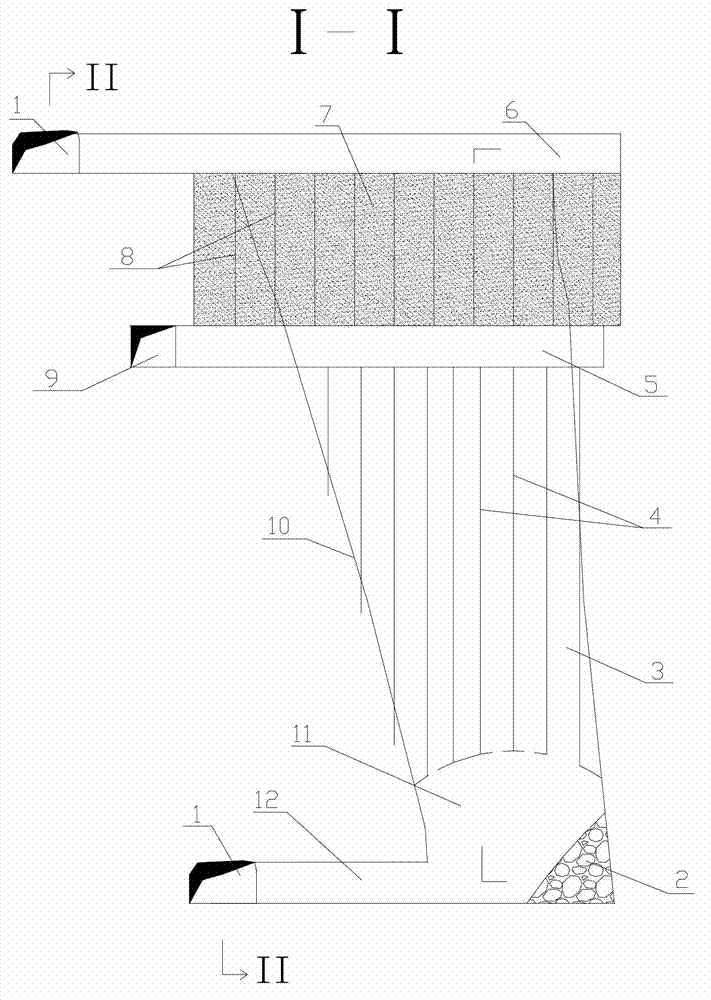

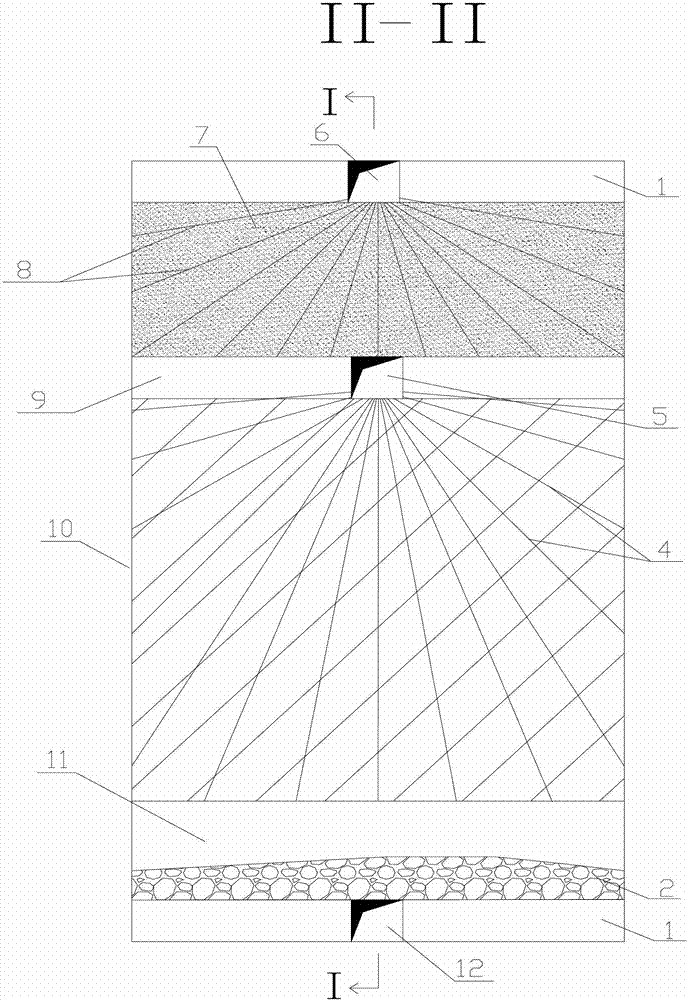

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] For the extremely unstable stope roof of the soft broken ore body with developed joints, fissures and water-conducting structures, the artificial freezing method is used to freeze the extremely unstable stope roof into a stable frozen body, and then use a large-scale method under the stable frozen roof. The mining process of large-diameter and deep hole collapse and subsequent filling, medium and deep hole collapse, filling the goaf at one time after the mining is completed, and finally thawing the frozen body.

[0015] see figure 1 and figure 2 , the vein-piercing roadway 6 is connected to the transport roadway 1 in the middle section, and within the stope boundary line 10, according to the structure size of the stope, first determine the technical requirements such as the freezing range and the strength of the frozen body, and carry out the freezing parameter des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com