tie rod guide

A technology of guides and tie rods, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems that the embedded pipe cannot fully guarantee the proper position, reduce the anti-corrosion effect of the cable body, scratches, scratches, etc. Economic benefits, good social benefits, and the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

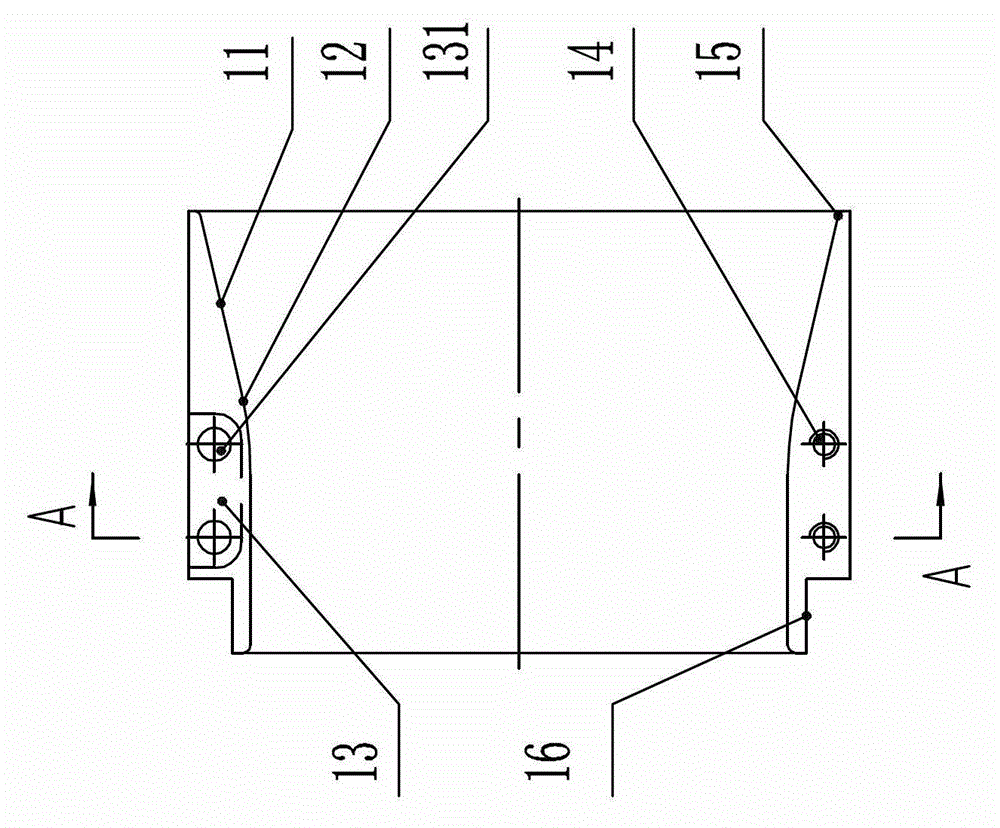

[0041] A tie rod guide composed of two semicircular arc-shaped shells, the tie rod guide is composed of two semicircular arc-shaped shells 11 to form an integral circular shell (see figure 2 ), both ends of the two semicircular arc-shaped shells are connected into one body by bolts;

[0042] Open a notch 13 at the interface on one side of each shell, and open two through holes 131 on it, and open two screw holes at the position corresponding to the through hole on the notch 13 on the other shell that needs to be connected 14. Bolts pass through the through holes and screw holes on the two shells, so as to connect the two shells into one body (see Figure 3-1~Figure 3-2 ); Figure 3-2 Indicates that the two shells of the tie rod guide are connected by bolts, Figure 3-1 A schematic diagram showing the structure of a shell of the tie rod guide.

Embodiment 2

[0044] A tie rod guide composed of two semicircular arc-shaped casings, the tie rod guide is composed of two semicircular arc-shaped casings 11 to form an integral circular ring-shaped casing, and one side of the two semicircular arc-shaped casings passes through Hinge 23 is integrated (referring to Figure 5-2 ), the connection on the other side is through buckle 22 (see Figure 5-1 ), bolts (see Figure 6-1 ) or connecting blocks and bolts with bolt holes welded on the ring housing (see Figure 10-2 ) connected into one.

Embodiment 3

[0046] A tie rod guide composed of two semicircular arc-shaped shells, the tie rod guide is composed of two semicircular arc-shaped shells to form an integral circular shell (see figure 2), one side of the two semicircular arc-shaped shells is fastened by bolts (see Figure 6-1 ), the connection on the other side is through a buckle (see Figure 5-1 ) or a connection block with bolt holes welded on the ring shell and bolted together (see Figure 10-2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com