Braid continuous mercerizing machine and processing method thereof

A mercerizing machine and fiber technology, used in yarn/thread/filament mercerization, continuous processing of textile materials, textiles and papermaking, etc., can solve the problem that fibers cannot be effectively mercerized, achieve gloss and strength improvement, and improve orientation. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

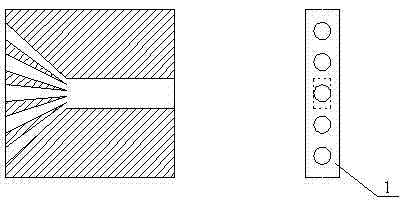

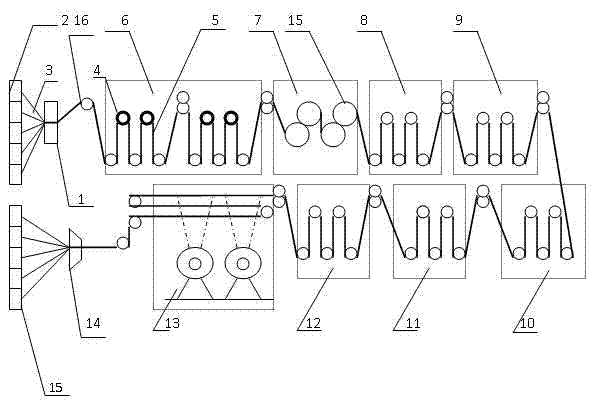

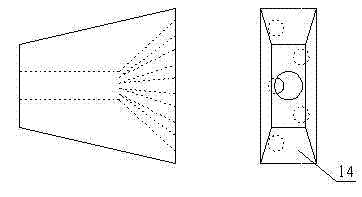

[0032] Such as figure 1 As shown, the structure of the fiber braid feeder is specifically a plate-shaped structure with holes at both ends, one end has a single long hole, and the other end has multiple round holes. After the holes meet, they form a single-strand fiber braid; as image 3 As shown, the structure of the bell-mouth lane divider is specifically in the shape of a truncated cone, with a single round hole at one end and multiple round holes at the other end. It is divided into independent fiber braids by the bell-mouth divider, which is convenient for the independent winding of the rear channel. Preferably, both the fiber braid feeder and the bell-mouth channel divider can be made of stainless steel.

[0033] attached figure 1 Among them, 5 fiber braids are inserted into the 5 round holes at the left end respectively, and after passing through the middle channel, they merge into a single fiber bundle, pass through the single long hole at the right end, and enter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com