Heat preservation plate in cross air blow device

A thermal insulation board and side air blowing technology, which is applied in the field of chemical fiber spinning, can solve problems such as increased frictional resistance between silk and air, shortened outlet deformation zone, and easy heat dissipation of fibers, so as to solve the problem of excessive wool, reduce broken ends, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

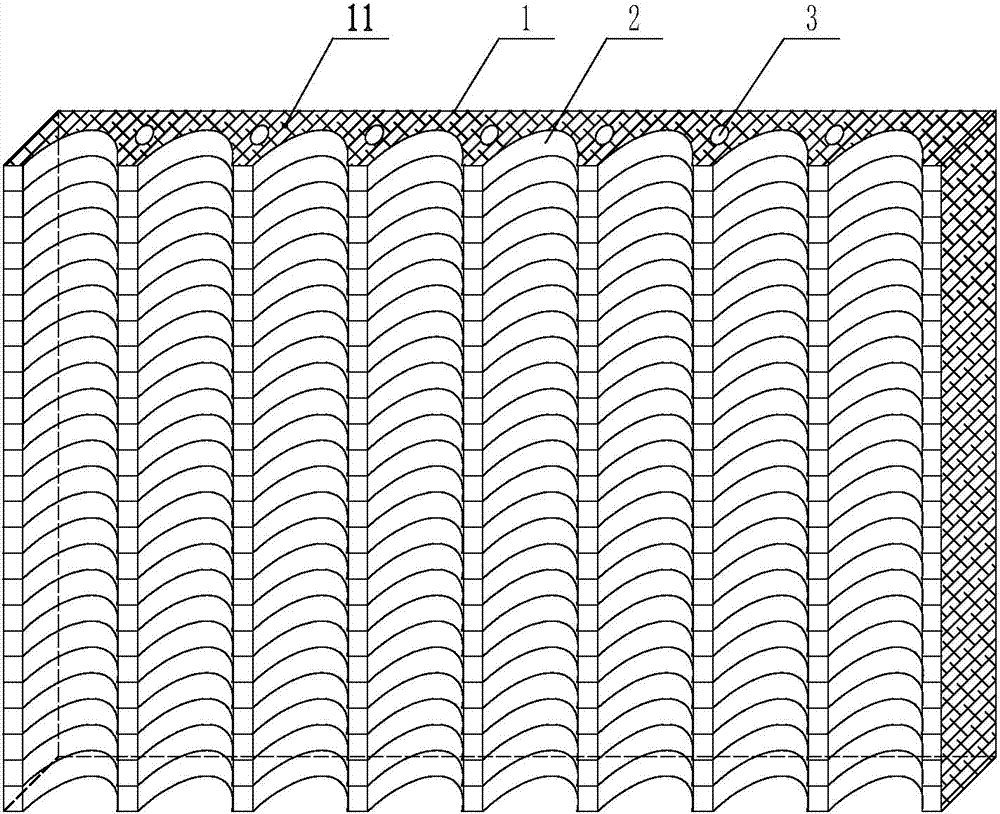

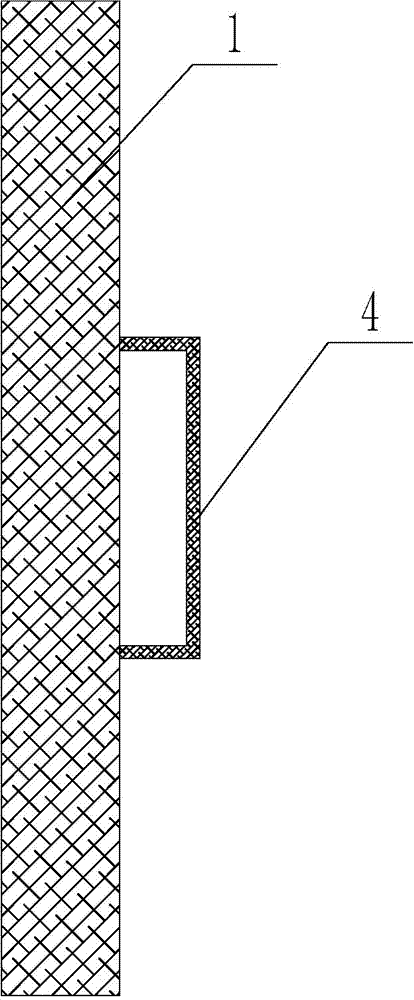

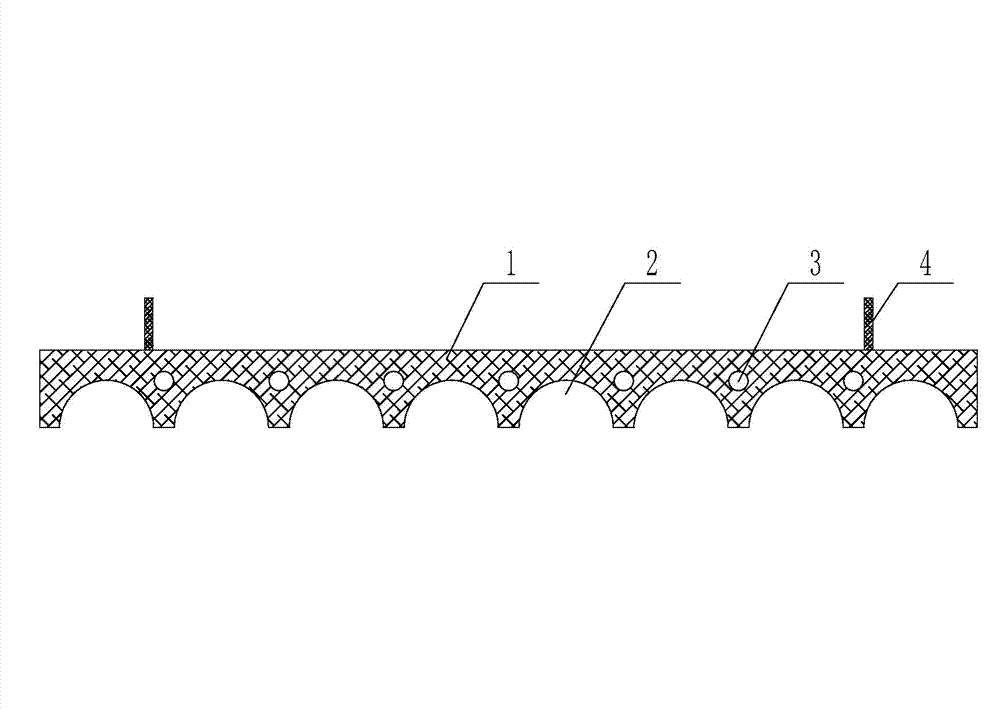

[0012] The insulation board in the side blowing device of the present invention will be described in further detail below through specific examples.

[0013] Such as figure 1 , figure 2 , image 3 As shown, the thermal insulation board in the side blowing device includes a thermal insulation board body 1, the length of the thermal insulation board body 1 matches the width of the side blower device, and the height of the thermal insulation board body 1 is established according to the needs of the production situation. There are several grooves 2 arranged in the body 1, the cross section of the grooves 2 is semicircular, the size of the grooves 2 matches the diameter of the spinnerets, and the number of the grooves 2 corresponds to the number of the spinnerets.

[0014] The thermal insulation board body 1 is formed by stacking several small thermal insulation boards 11, each small thermal insulation board 11 is provided with a connection hole 3 at a corresponding position on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com