Environment-friendly shield tail sealing grease, preparation method and application thereof

A shield tail sealing and environmentally friendly technology, applied in the direction of lubricating composition, etc., to achieve the effects of excellent pumpability, stable performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] The preferred embodiment of the environment-friendly shield tail sealing grease of the present invention is:

[0015] It includes the following components according to the mass ratio: 5-20 parts of base oil, 15-30 parts of viscosity index improver, 10-25 parts of lubricant, 4-10 parts of natural degradable fiber, 35-50 parts of filling granular material, Synthetic polymer 0.5-3 parts.

[0016] The base oil is any one or more of the following: 32# mechanical hydraulic oil, 46# mechanical hydraulic oil, 68# mechanical hydraulic oil, anti-wear hydraulic oil.

[0017] The viscosity index improver is any one or more of the following: T612, T613, T614, coumarone, rosin, C5 petroleum resin, C9 petroleum resin.

[0018] The lubricant is any one or more of the following: 2# lithium-based grease, 3# lithium-based grease, extreme pressure lithium-based grease.

[0019] The natural degradable fiber is any one or more of the following: fibers extracted from trees and fibers extrac...

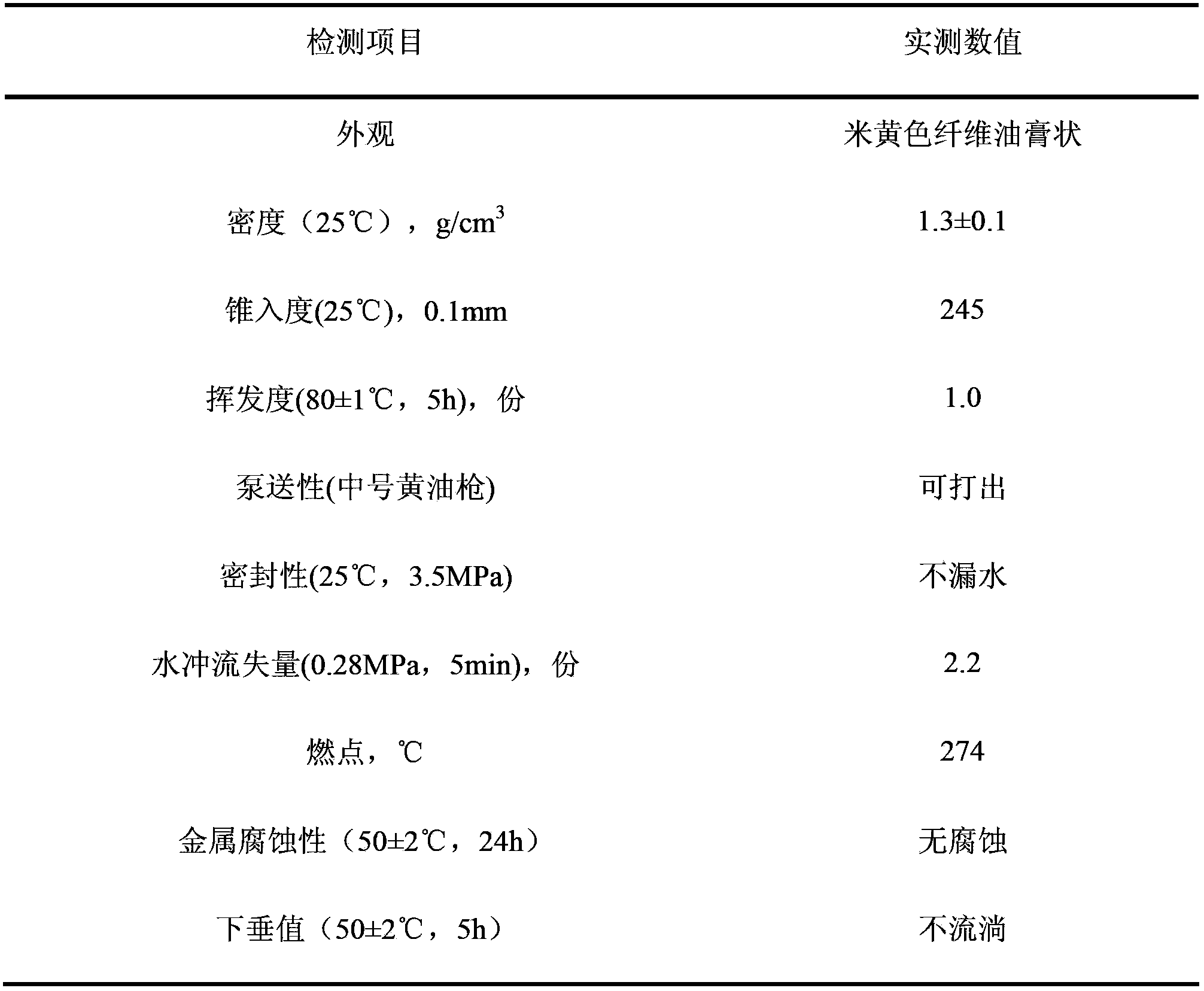

Embodiment 1

[0030] Add 30kg of 32# mechanical hydraulic oil, 50kg of viscosity index improver (m(T612): m(C5)=1~4), and 50kg of 3# lithium base grease into the kneader, and heat up to 60~90 while stirring and kneading. ℃, continue stirring and kneading for about 1~4h, then cool down to 30~50℃. Then add 107.5kg of light calcium carbonate (5:3:2 in batches) and stir at constant temperature for 5~10min, then add 10kg of natural degradable wood fiber and 2.5kg of synthetic polymer, and knead and stir at constant temperature for 1~3h to get Shield tail seal grease.

Embodiment 2

[0032] Add 30kg of 46# mechanical hydraulic oil, 55kg of viscosity index improver (m(T613):m(C9)=1~4), and 45kg of extreme pressure lithium base grease into the kneader, and heat up to 60~90 while stirring and kneading. ℃, continue stirring and kneading for about 1~4h, then cool down to 30~50℃. Then add 103.75kg of light calcium carbonate (5:3:2 in batches) and stir at constant temperature for 5~10min, then add 15kg of natural degradable cotton fiber and 1.25kg of synthetic polymer, and knead and stir at constant temperature for 1~3h. Get shield tail seal grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com