Multi-shell-structure quantum dot composite particle, and high-fluorescent-brightness quantum dot probe and preparation method thereof

A technology of composite particles and quantum dots, which is applied in the direction of chemical instruments and methods, luminescent materials, material inspection products, etc., can solve the problem of affecting the accuracy and repeatability of the detection response of the substance to be tested, severe impact, unstable physical and chemical properties, etc. problems, achieve good biological adaptability and stability, good effect, and improve the effect of fluorescence brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1.1 The CdTe quantum dots were synthesized by the aqueous phase method. First synthesize the NaHTe required for the preparation of CdTe quantum dots: combine Te powder with NaBH 4 Mix according to the molar ratio of 1:10, add 2ml of water, heat in a water bath at 60 degrees Celsius under nitrogen protection and stir until the solution turns lavender. 0.4 mmol of CdCl 2 2.5H 2 O was dissolved in 25 mL of water, 0.6 mmol of thioglycolic acid (TGA) was added, stirred, and then 1M NaOH solution was added until the pH value of the solution was adjusted to 11.2. The solution was deoxygenated with nitrogen for 30 minutes, then injected into the NaHTe solution prepared above, and heated to reflux at 100 degrees Celsius for 10 minutes to obtain water-soluble green-emitting CdTe quantum dots (particle size: 1.5 nm, wavelength: 520 nm).

[0053] 1.2 Add 0.5 mmol of CdCl 2 2.5H 2 Dissolve O in 10 mL of water, add 0.75 mmol TGA, that is, the molar ratio of mercapto compound to ...

Embodiment 2

[0061] 2.1 CdTe quantum dots were synthesized by the aqueous phase method. First synthesize the NaHTe required for the preparation of CdTe quantum dots: combine Te powder with NaBH 4 Mix according to the molar ratio of 1:10, add 2ml of water, heat in a water bath at 60 degrees Celsius under nitrogen protection and stir until the solution turns lavender. 0.4 mmol of CdCl 2 2.5H 2 O was dissolved in 25 mL of water, 0.6 mmol of mercaptoethanol was added, stirred, and then 1M NaOH solution was added until the pH value of the solution was adjusted to 11.2. The solution was deoxygenated with nitrogen for 30 minutes, then injected into the NaHTe solution prepared above, and heated to reflux at 100 degrees Celsius for 4 hours to obtain water-soluble yellow fluorescent CdTe quantum dots (particle size: 3.2 nm, wavelength: 580 nm) .

[0062] 2.2 Add 0.5 mmol of CdCl 2 2.5H 2 Dissolve O in 10 mL of water, add 1 mmol TGA, that is, the molar ratio of mercapto compound to cation is 2:...

Embodiment 3

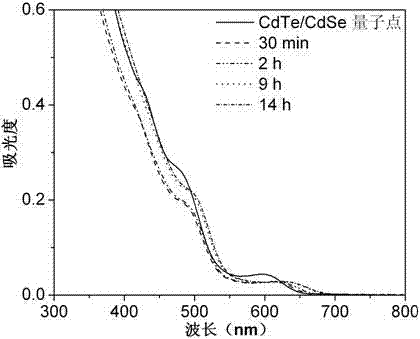

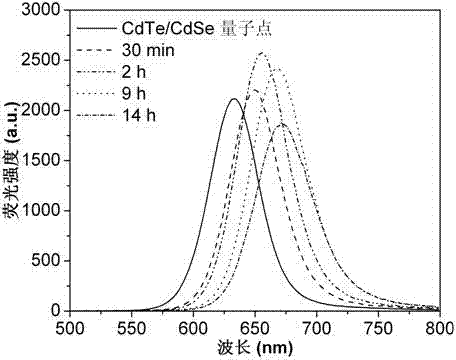

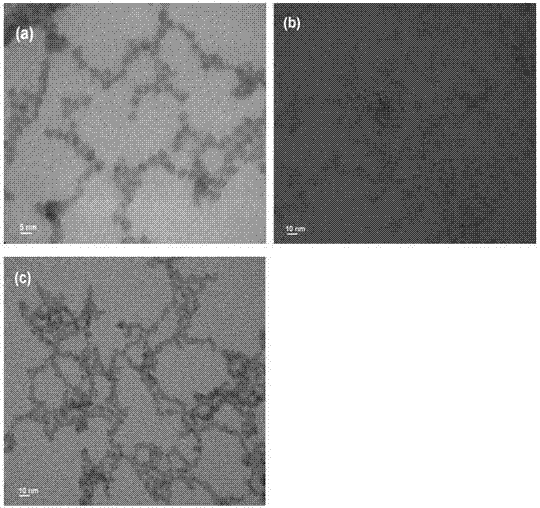

[0070] 3.1 The CdTe quantum dots were synthesized by the aqueous phase method. First synthesize the NaHTe required for the preparation of CdTe quantum dots: combine Te powder with NaBH 4 Mix according to the molar ratio of 1:10, add 2ml of water, heat in a water bath at 60 degrees Celsius under nitrogen protection and stir until the solution turns lavender. 0.4 mmol of CdCl 2 2.5H 2 O was dissolved in 25 mL of water, 0.6 mmol of thioglycolic acid (TGA) was added, stirred, and then 1M NaOH solution was added until the pH value of the solution was adjusted to 11.2. The solution was deoxygenated with nitrogen for 30 minutes, then injected into the NaHTe solution prepared above, and heated to reflux at 100 degrees Celsius for 18 hours to obtain water-soluble red fluorescent CdTe quantum dots (particle size: 3.48 nm, wavelength: 620 nm) ,like image 3 shown in (a). fluorescence spectrum at Figure 4 middle.

[0071] 3.2 Add 0.5 mmol of CdCl 2 2.5H 2 Dissolve O in 10 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com