Method for preparing fullerene nano micron material loaded with transition metal and product of fullerene nano micron material

A transition metal and fullerene technology, applied in the field of preparation of fullerene nano-micron materials, can solve the problems of long growth period of nanotubes, difficult large-scale preparation, long growth period, etc. good environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Weigh 0.005g of C60 and place it in a glass bottle with a purity of 99.9%. For a commercially available product, take 5ml of carbon disulfide with a pipette and add it to the glass bottle, sonicate for 30 minutes, filter, and store at 0-5°C.

[0033] 2. Weigh a certain amount of nickel nitrate, add it to isopropanol to prepare a Ni-containing isopropanol solution, and store it at 0-5°C.

[0034] 3. Slowly add the Ni-isopropanol solution in step 2 to the solution prepared in step 1 at a ratio of 6:1 by volume, let it stand at 5°C for 5 minutes, then sonicate for 1 minute, and place it in an incubator at 8°C Constant temperature growth.

[0035] 4. Characterization

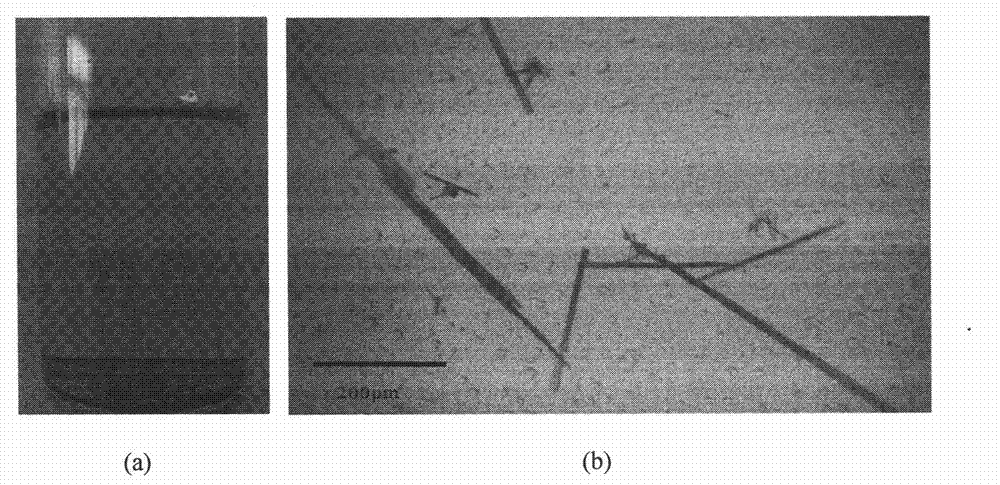

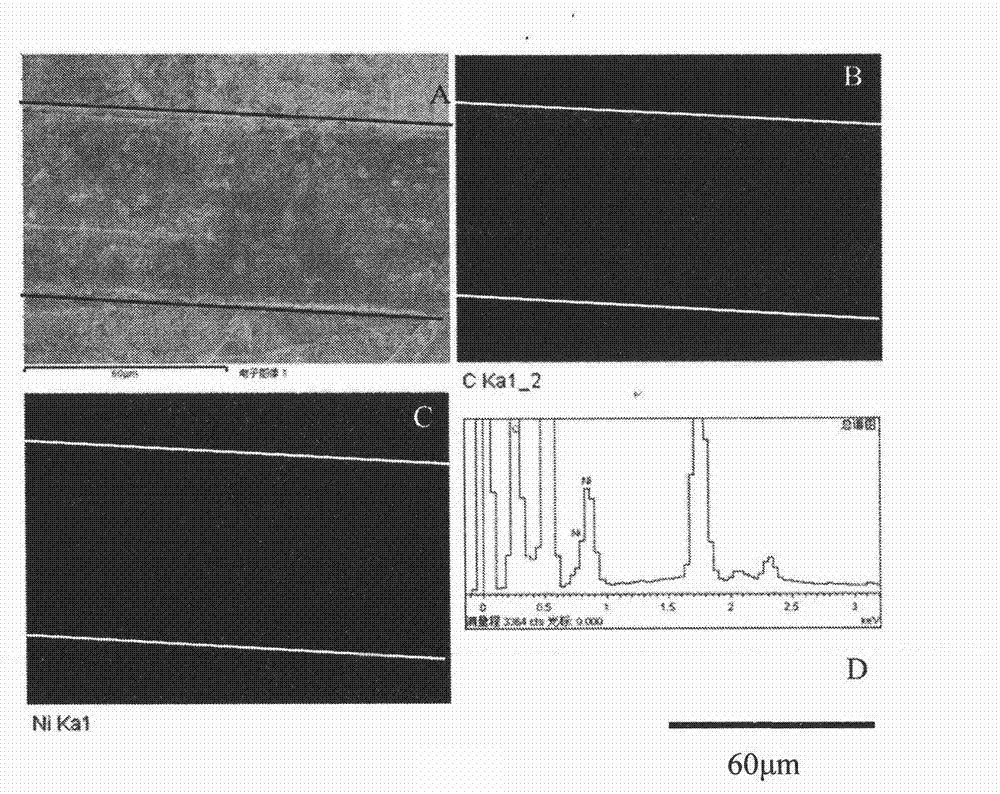

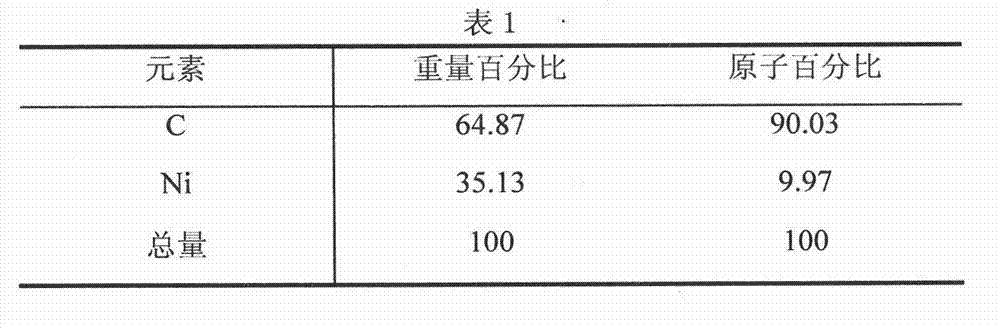

[0036] The loaded transition metals prepared by polarizing optical microscopy (POM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), energy dispersive spectrometer (EDS) Characterization of the morphology, structure and elemental composition of fullerene-like nano-micro-materi...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that in step 1: take 0.01g C 60 , with a purity of 99.9%, a commercially available product, ground to a metallic luster with an agate mortar, making C 60 Spread evenly on the inner surface of the mortar, add carbon disulfide to the mortar several times with a pipette to make C 60 Dissolve the powder and wash the mortar, and the resulting C 60 -The solution of carbon disulfide is transferred to a glass bottle, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0043] The difference between Example 3 and Example 1 is that in step 1: after ultrasonication for 30 min, irradiate with self-light for 30-60 min in an ice-water bath at 5°C, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com