Prehydration-type geosynthetic clay liner and preparation method thereof

A bentonite waterproof blanket and pre-hydration technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of poor anti-pollution effect, decreased anti-seepage effect, and long time required. Achieve the effect of increasing construction difficulty, facilitating promotion and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

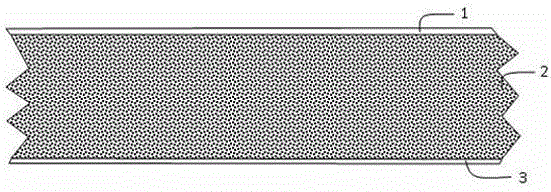

Image

Examples

Embodiment 1

[0030] ① The natural sodium-based bentonite raw ore is dried and crushed and passed through a 50-mesh sieve to make bentonite powder with an expansion index ≥ 24ml / 2g, a filtration loss of 12ml, and a water content of 10%;

[0031] ② Fully mix 8 parts of bentonite powder, 1 part of sodium polyacrylate, and 0.67 parts of sodium hydroxide, and send the mixture to the continuous stirring reactor through the feeder at a uniform speed, and spray 5 parts of water evenly on the surface of the mixture while conveying, Water is industrial water with a total cationic content of ≤300mg / l. Under the action of a high-speed, high-shear stirring gear, the mixture is stirred and sheared into a uniform mass with toughness. The speed is 90r / min, and the reaction time is 8min. .

[0032] ③Convey the uniform agglomerate to the vacuum screw extruder, vacuumize under the pressure of 2Mpa to remove excess air and moisture in the agglomerate, and increase the product density; Pushed into the annular...

Embodiment 2

[0035] ①The natural sodium-based bentonite raw ore is dried and crushed and passed through a 100-mesh sieve to make bentonite powder with an expansion index ≥ 24ml / 2g, a filtration loss of 18ml, and a water content of 15%;

[0036] ② Fully mix 10 parts of bentonite powder, 1 part of corn starch, and 0.83 parts of sodium carboxymethyl cellulose, and send the mixture to the continuous stirring reactor through the feeder at a uniform speed, and spray 6 parts of water evenly on the mixture while conveying On the surface, the water is tap water with a total cation content of ≤300mg / l. Under the action of a high-speed, high-shear stirring gear, the mixture is stirred and sheared into a uniform mass with toughness. The speed is 90r / min, and the reaction time is 12min.

[0037] ③Convey the uniform agglomerate to the vacuum screw extruder, vacuumize to remove excess air and moisture in the agglomerate, and increase the product density; the agglomerate after vacuuming is continuously pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| swell index | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com