Rotary atomizing painting device

一种旋转雾化、涂装的技术,应用在喷雾放电装置、喷射装置、静电喷射装置等方向,能够解决涂敷图案狭窄、涂装时间缩短、不能有效地实现涂敷图案扩大等问题,达到实现微粒化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, embodiments of the present invention will be described.

[0031] First, refer to Figure 1 to Figure 4 The overall configuration of the rotary atomization coating device according to the first embodiment of the present invention will be described. Additionally, the figure 1 The direction of the arrow X shown in , is defined as the spraying direction of the paint, that is, the front, and the following description will be made.

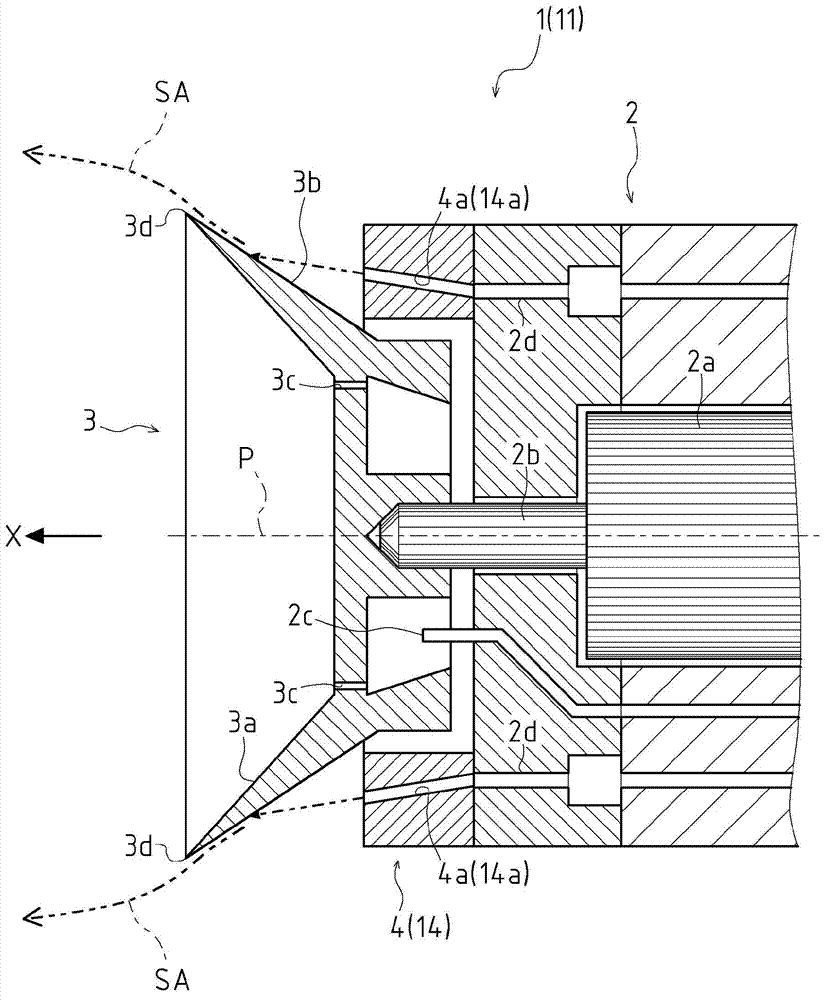

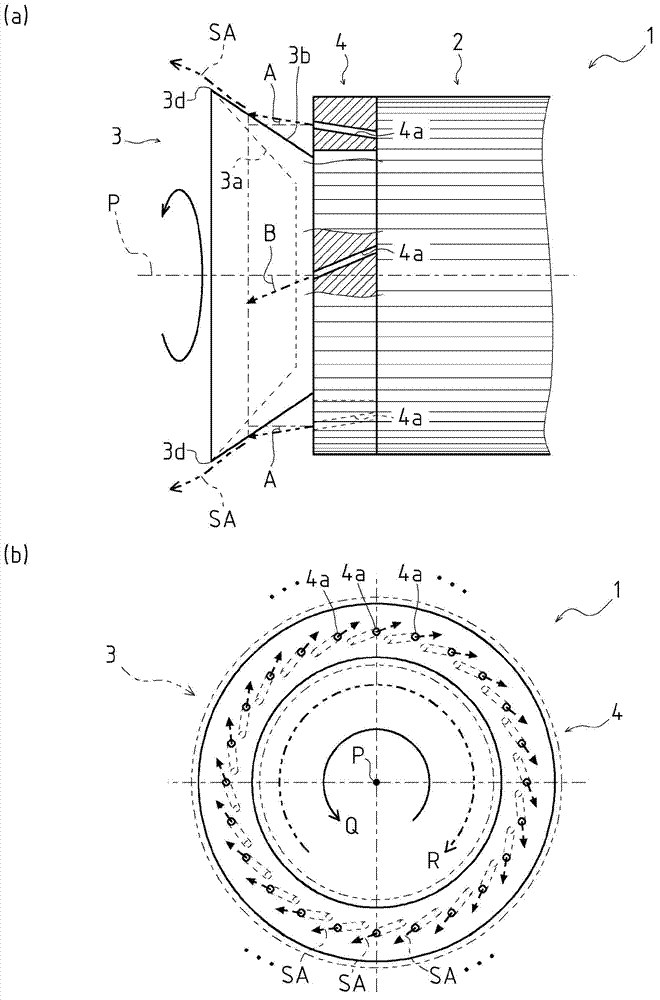

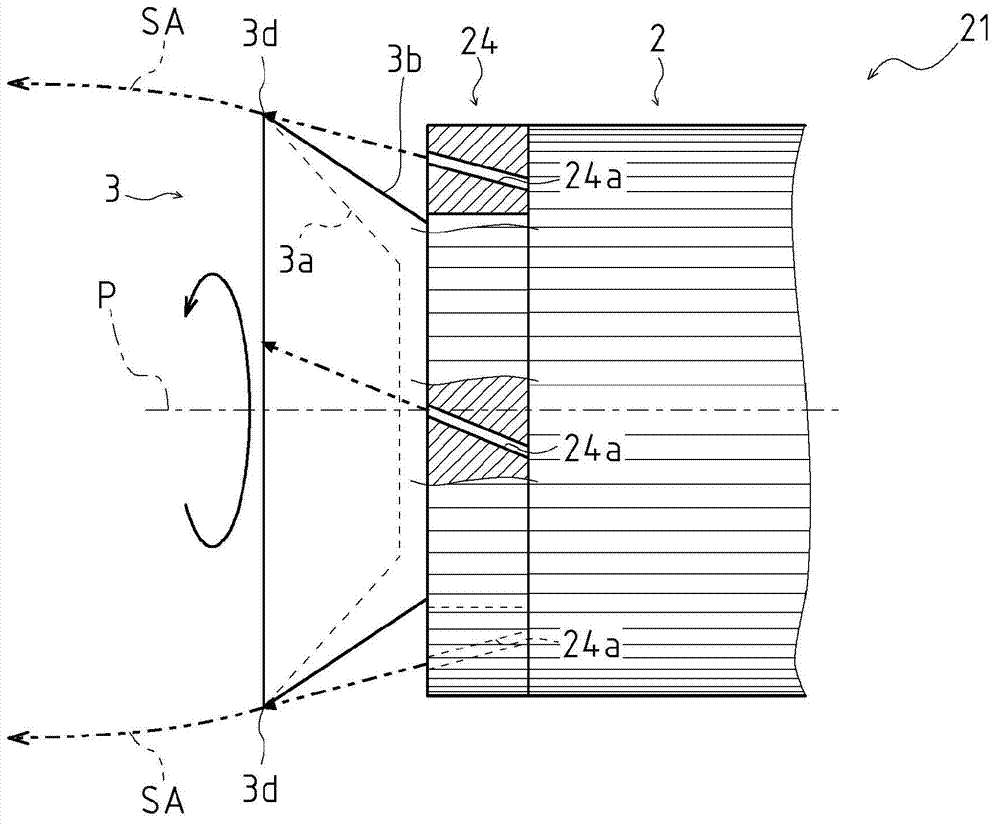

[0032] Such as figure 1 As shown, the coating gun 1 as the rotary atomization coating device according to the first embodiment of the present invention is a coating device for spraying atomized paint on an object to be coated used in electrostatic coating, and includes a gun main body 2 , rotary cup 3, forming air ring 4.

[0033] The gun body 2 is supported by a manipulator (not shown) for displacing the coating gun 1 in a desired position and posture, and is provided with a rotary cup 3 and / or a forming air ring 4, and an air motor 2a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com