Top punching die for lamp shade

A technology for punching dies and lampshades, applied in the field of punching dies, can solve problems such as inconvenient positioning, high labor intensity, and low precision, reduce production costs and labor intensity, avoid inaccurate side hole positions, and improve product quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

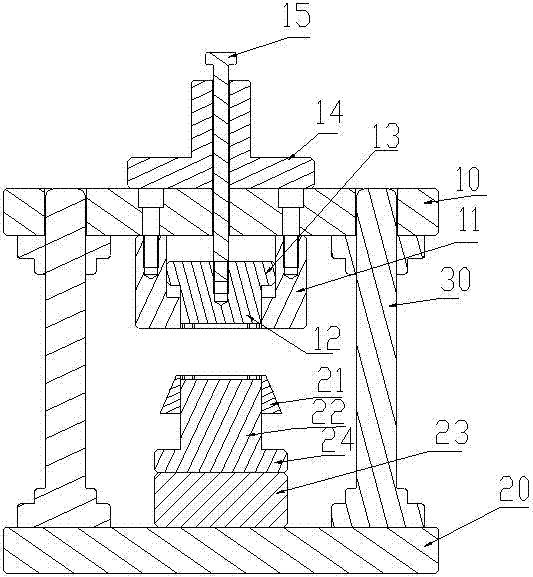

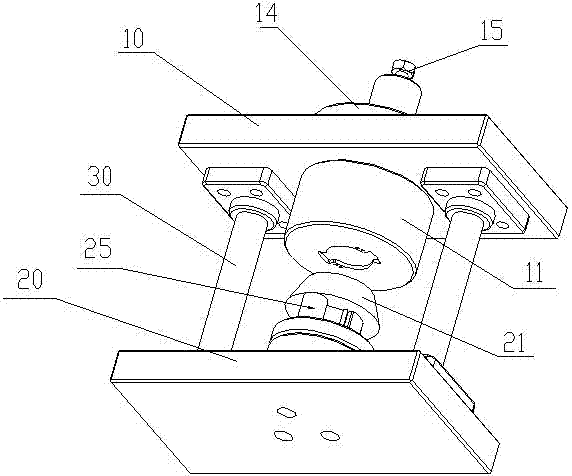

[0018] see figure 1 and figure 2 , the present embodiment is a lampshade top punching die, which includes an upper template 10 and a lower template 20 and a guide column 30 connecting the upper and lower templates, a die 11 is installed on the lower surface of the upper template 10, and the die 11 is installed There is a discharge plate 12, the discharge plate 12 is set in the die 11 through the discharge fixed plate 13, and a limit stopper for limiting the discharge fixed plate 13 is arranged in the die 11, so as to limit the discharge plate 12 of the shedding. A mold handle 14 is installed on the upper surface of the upper template 10, and a knockout rod 15 connected to the discharge plate 12 is installed on the mold handle 14, and the knocko...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com