Multi-angle air-blowing device

A blowing device, multi-angle technology, applied in the cleaning method, cleaning method and utensil, chemical instrument and method using gas flow, etc. The effect of avoiding residues and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

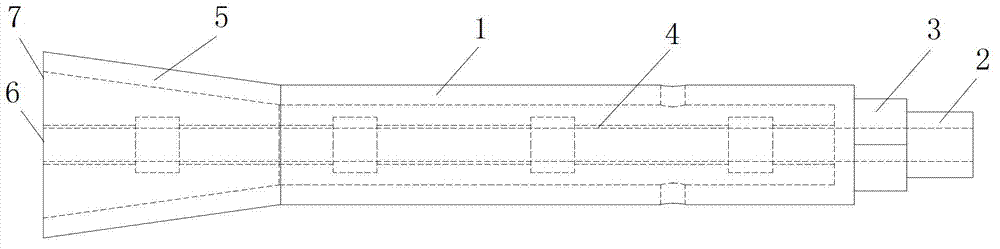

[0011] Such as figure 1 As shown, a multi-angle blowing device includes a long pipe 1, a short pipe 2, a joint 3 and a hose 4, the tail end of the long pipe 1 is connected with the front end of the short pipe 2 through the joint 3, and the long pipe 1 is provided with a hose 4, the tail end of the hose 4 extends into the short pipe 2 through the joint 3, the tail end of the short pipe 2 is connected to the air compressor, and the front end of the long pipe 1 is designed The hose 4 extends into the horn-shaped opening 5, and the front end surface 6 of the hose 4 and the opening surface 7 of the horn-shaped opening 5 are located in the same plane.

[0012] To sum up, in the present invention, the front end of the long tube 1 is designed as a trumpet-shaped opening 5 , and the hose 4 extends into the trumpet-shaped opening 5 . When the air compressor blows air to the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com