Composite electromagnetic shielding material and method for manufacturing same

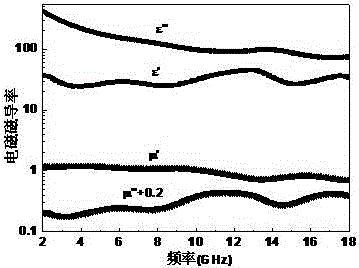

A shielding material and composite electromagnetic technology, which is applied in the field of electromagnetic pollution prevention and microwave anechoic chambers, can solve the problems of difficult uniform dispersion, high cost and low output of carbon nanomaterials, and achieve the effects of easy dispersion, high production efficiency and large electrical loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

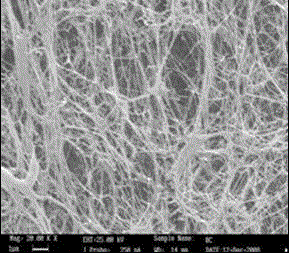

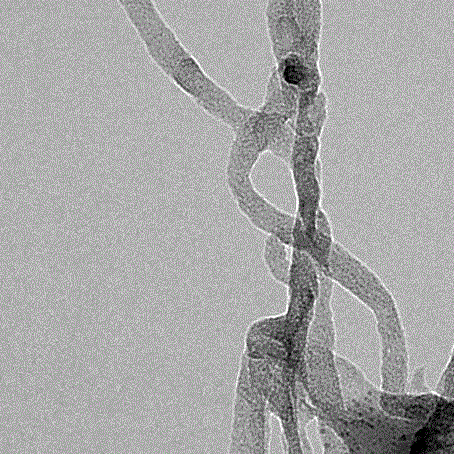

[0038] A composite electromagnetic shielding material, which is composed of carbonized bacterial cellulose and matrix material paraffin;

[0039] The preparation method of the composite electromagnetic shielding material comprises the following steps:

[0040] a. Bacterial cellulose is obtained by static shallow plate culture, which is the same as the prior art;

[0041] b. Carbonized bacterial cellulose: the process parameters are: the carbonization temperature of bacterial cellulose is 800-1600 ℃, the background vacuum pressure is 10 -2 ~10 4 Pa, the holding time is 0.5 h ~ 4 h;

[0042] C, get the paraffin wax with the equal volume of carbonized bacterial cellulose;

[0043] d. Mix carbonized bacterial cellulose and paraffin wax at a volume ratio of 1:1, heat the mixture to 90 ℃ ~ 92 ℃, stir mechanically for 30 ~ 50 minutes, and then ultrasonically mix in a water bath at 85 ℃ ~ 90 ℃ for 20 ~ 50 minutes After cooling.

Embodiment 2

[0045] A composite electromagnetic shielding material, which is composed of carbonized bacterial cellulose and epoxy resin as a matrix material;

[0046] The preparation method of the composite electromagnetic shielding material comprises the following steps:

[0047] a. Bacterial cellulose is obtained by static shallow plate culture, which is the same as the prior art;

[0048] b. Carbonized bacterial cellulose: the process parameters are: the carbonization temperature of bacterial cellulose is 800-1600 ℃, the background vacuum pressure is 10 -2 ~10 4 Pa, the holding time is 0.5 h ~ 4 h;

[0049] C, get the epoxy resin of equal volume with the carbonized bacterial cellulose;

[0050] d. Mix the carbonized bacterial cellulose and epoxy resin at a volume ratio of 1:1, stir the mixture mechanically for 30-50 minutes, and let it stand for 1 day to naturally cure.

Embodiment 3

[0052] A carbonized bacterial cellulose electromagnetic shielding material, which is composed of a carbonized bacterial cellulose and a matrix material silicon dioxide;

[0053] The preparation method of the carbonized bacterial cellulose electromagnetic shielding material comprises the following steps:

[0054] a. Bacterial cellulose is obtained by static shallow plate culture, which is the same as the prior art;

[0055] b. Carbonized bacterial cellulose: the process parameters are: the carbonization temperature of bacterial cellulose is 800-1600 ℃, the background vacuum pressure is 10 -2 ~10 4 Pa, the holding time is 0.5 h ~ 4 h;

[0056] c, get silicon dioxide equal to the volume of carbonized bacterial cellulose;

[0057] d. Mix the carbonized bacterial cellulose and silicon dioxide at a volume ratio of 1:1, stir the mixture mechanically for 60 minutes and then solidify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com