Resistance random access memory based on vanadium oxide/zinc oxide laminated structure and preparation method thereof

A technology of resistive memory and stacked structure, which is applied in the field of microelectronics to achieve the effect of improving consistency and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

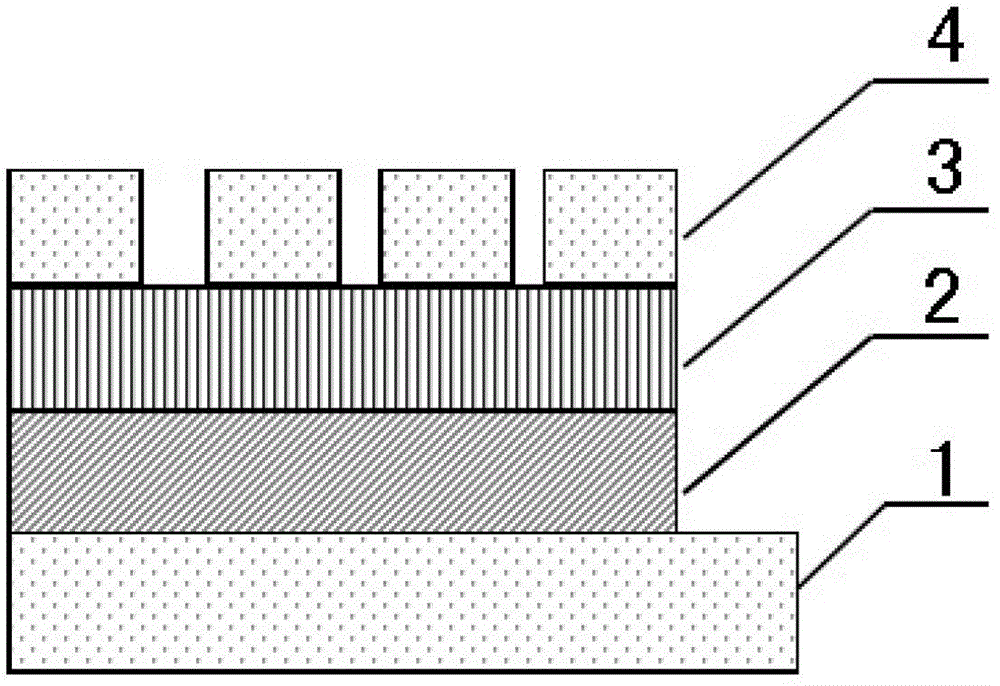

[0029] A resistive variable memory based on a vanadium oxide / zinc oxide stack structure, such as figure 1 As shown, it is composed of a lower electrode 1, a resistive layer and an upper electrode 4. The resistive layer is a laminated structure composed of a vanadium oxide dielectric layer 2 and a zinc oxide dielectric layer 3. The composition of zinc oxide is ZnO 1-x , where x is 0.1, the thickness of the zinc oxide dielectric layer is 30nm; the composition of vanadium oxide is VO y , wherein y is 0.15, the thickness of the vanadium oxide dielectric layer is 30nm; the lower electrode is Pt, the thickness is 50nm, and the upper electrode is W, the thickness is 50nm.

[0030] The preparation method of the resistive memory, the steps are as follows:

[0031] 1) Si wafers are used as substrates, and SiO is prepared on silicon substrates by thermal oxidation using an oxidation diffusion furnace. 2 Insulation;

[0032] 2) On SiO 2 A 10nm thick Ti adhesion layer was prepared on t...

Embodiment 2

[0040]A resistive variable memory based on a vanadium oxide / zinc oxide laminated structure, the structure is basically the same as that of Embodiment 1, except that W is the lower electrode with a thickness of 50nm, and TiN is the upper electrode with a thickness of 100nm.

[0041] The preparation method of the resistive memory, the steps are as follows:

[0042] 1), 2) are the same as embodiment 1;

[0043] 3) On the Ti adhesion layer, deposit a tungsten lower electrode with a thickness of 50nm by DC magnetron sputtering. The process parameters of DC magnetron sputtering: the target is a φ60mm metal tungsten target, the target intercept is 6.5cm, and the working pressure is 0.5 Pa, Ar flow rate is 20sccm, sputtering power is 50W;

[0044] 4) Deposit a vanadium oxide film with a thickness of 30nm on the lower electrode by radio frequency sputtering. The sputtering process conditions are: the target is a φ60mm vanadium oxide ceramic target, the target intercept is 6.5cm, and t...

Embodiment 3

[0050] A resistive variable memory based on a vanadium oxide / zinc oxide stack structure, the structure is basically the same as that of embodiment 1, the difference is that W is the bottom electrode, W is the top electrode, and the thickness is 50nm.

[0051] The preparation method of the RRAM, the steps and the preparation process of the W electrode are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com