Large-size full-color OLED (Organic Light-Emitting Diode) display

A large-scale, display technology, used in instruments, electrical solid-state devices, semiconductor devices, etc., can solve the problems of backward blue OLED materials, poor color stability, backwardness, etc., and achieve the size and size that can be easily realized, improve cost-effectiveness, and have good visual effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

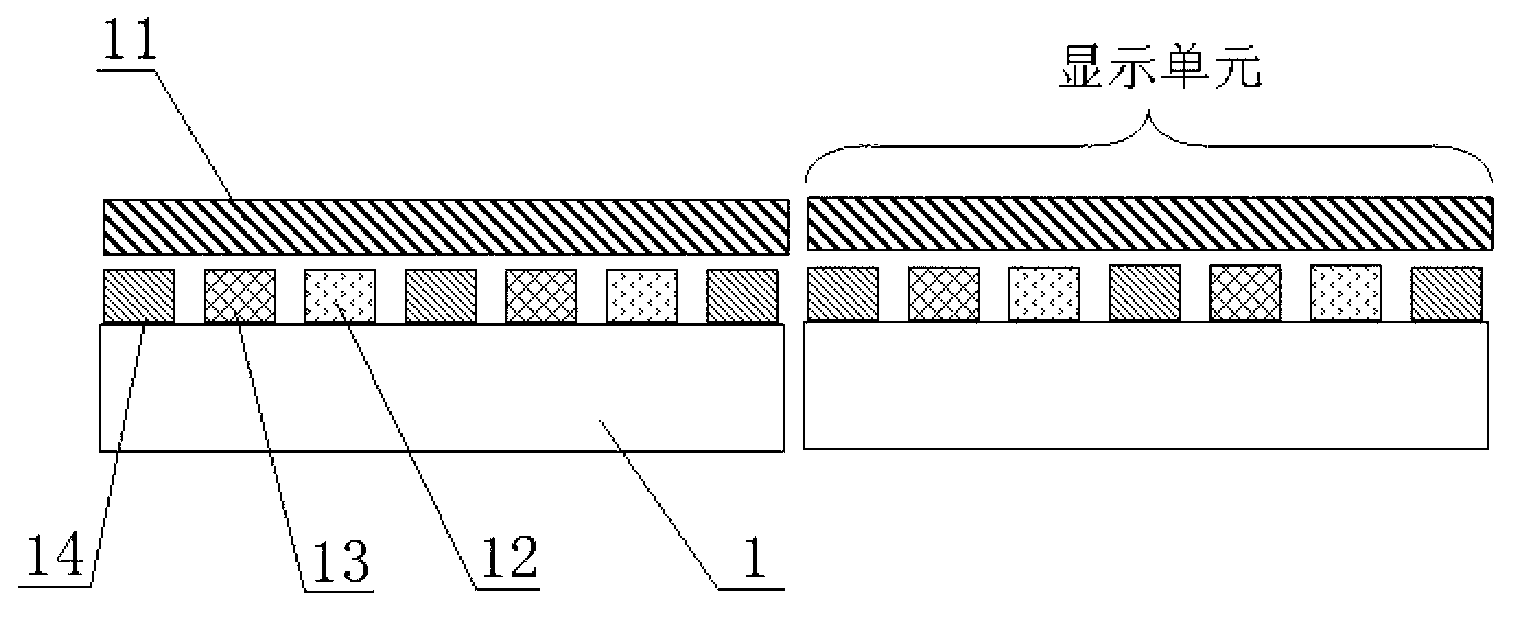

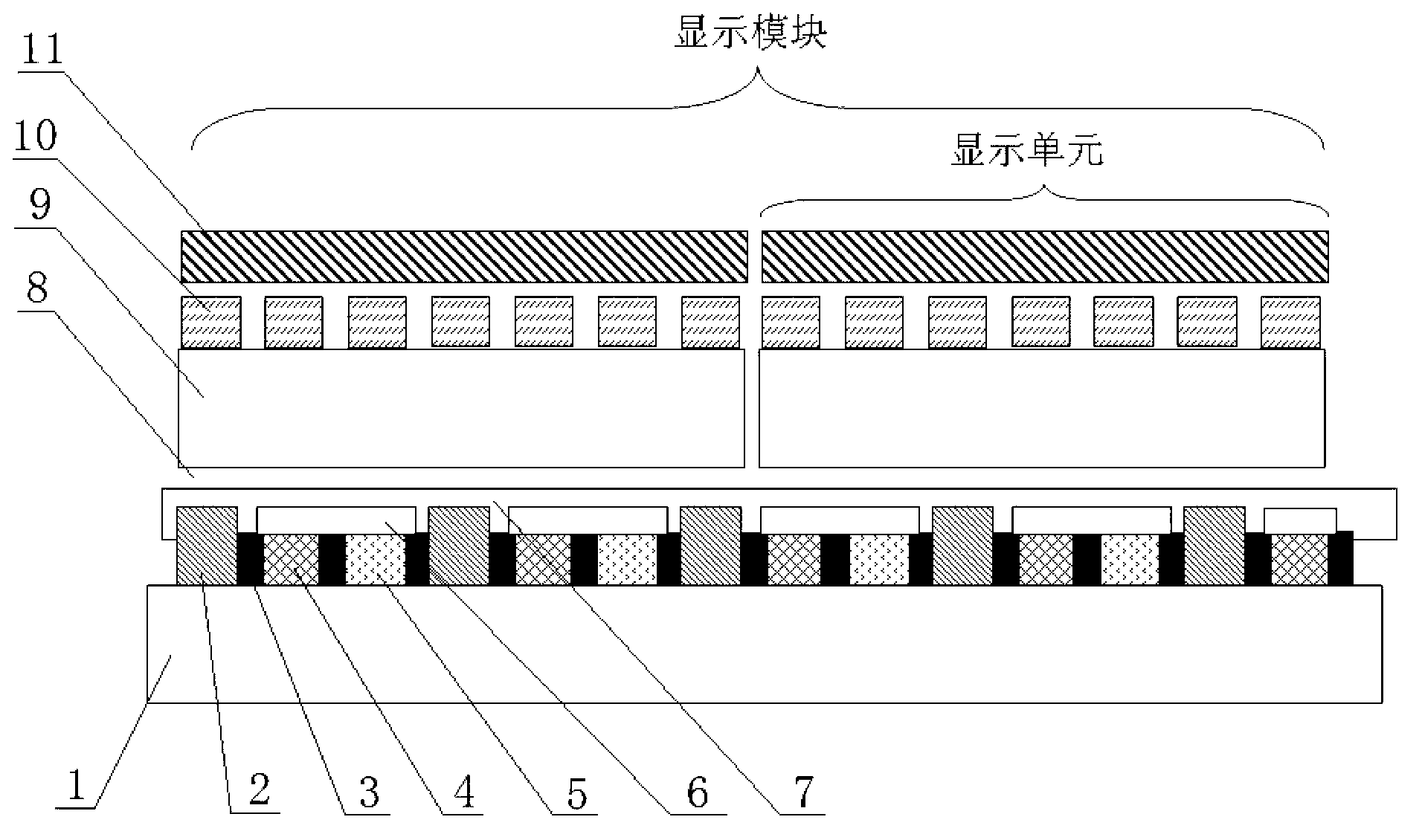

[0105] figure 2 Shown is the first structure of the large-size full-color OLED display of the present invention, which includes a complete color conversion substrate and a display module composed of a plurality of display units. The color conversion substrate includes a transparent substrate 1, and the transparent substrate One surface of 1 is covered with a red filter film layer 5, a green filter film layer 4 and a blue filter film layer 2, and a black matrix net is arranged between the filter film layers of various colors grid film layer 3; its innovative point is: the green filter film layer 4, the red filter film layer 5 and the black matrix grid film layer 3 between them are fully covered with the same green color transformation The green color conversion film layer 6 made of material; the display module is composed of a plurality of display units spliced together, and each display unit includes a light-transmitting substrate 9, a plurality of OLED light-emitting devic...

Embodiment 2

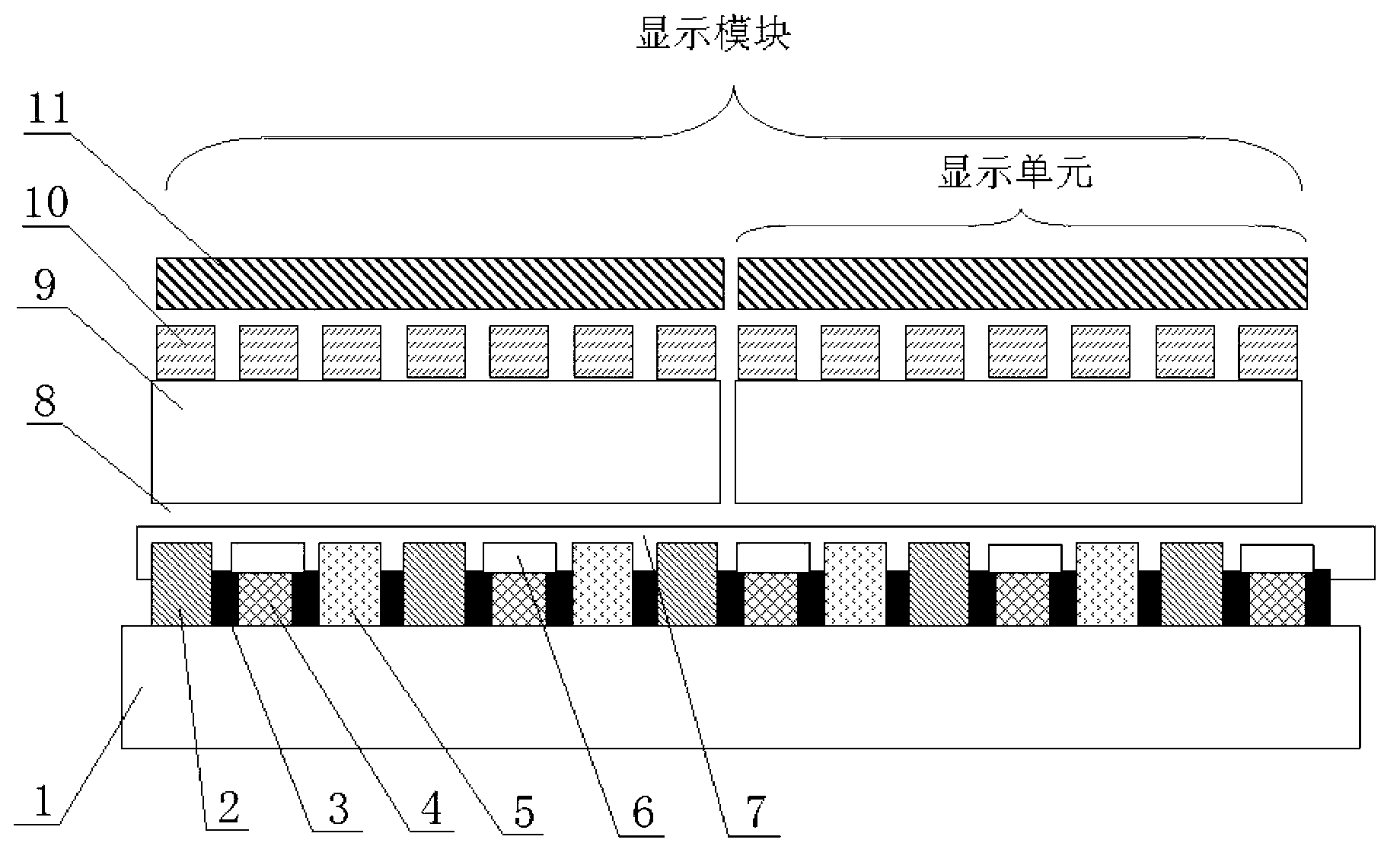

[0160] image 3 Shown is the second structural form of the large-size full-color OLED display of the present invention, which is the same as figure 2 The structural form shown in the difference is that the green color conversion film layer 6 does not continuously cover the red filter film layer 5, the green filter film layer 4 and the black matrix grid film layer 3 between them , but only covers the green filter film layer 4. This composition feature is only a difference in the selectivity of the process of the color change film layer, and does not affect the performance of the large-size full-color OLED display.

manufacture Embodiment 1

[0162] Manufacturing steps process:

[0163] 1. Production of color changing substrate:

[0164] (1) In the form of entrusted processing, the black matrix grid film layer 3, the red filter film layer 5, the green filter film layer 4 and the blue The filter glass of the filter film layer 2 has a specification size of 2.4 inches QVGA, in which the thickness of the red filter film layer 5 is 3 microns, the thickness of the green filter film layer 4 is 3 microns, and the blue film layer 4 has a thickness of 3 microns. The thickness of the filter film layer 2 is 6 microns, and the transmittances of the above-mentioned different color filter film layers are as follows: Figure 6 shown.

[0165] (2) According to figure 2 In the shown structure, the green color conversion film layer 6 is continued to be made on the above-mentioned light filter film glass. In the manufacturing example 1, the green color-changing film layer 6 is in the form of photoresist, specifically, the green c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com