Pretreatment method for silylation and silylation method comprising same

A monosilane and pretreatment technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as peeling, particles in the layer, and failure of resist patterns, and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The system for silylation includes: a heating system, a processing chamber, a silylating agent input port, a nitrogen gas input port, an exhaust port, a vacuum system, and a control module.

[0028] Turn on the heating system, control the constant temperature of the processing chamber at 125°C, put the wafer to be processed into the processing chamber, blow in nitrogen, and control the flow rate to 10,000 milliliters / minute (ml / min). After 10s, the mixed gas of HMDS and nitrogen is introduced. The volume ratio of HMDS and nitrogen is: 45:55. After the control flow is 15s, the mixed gas is stopped and the nitrogen is continued. The control flow is 2000 ml / min (ml / min ), and exhaust from the exhaust port.

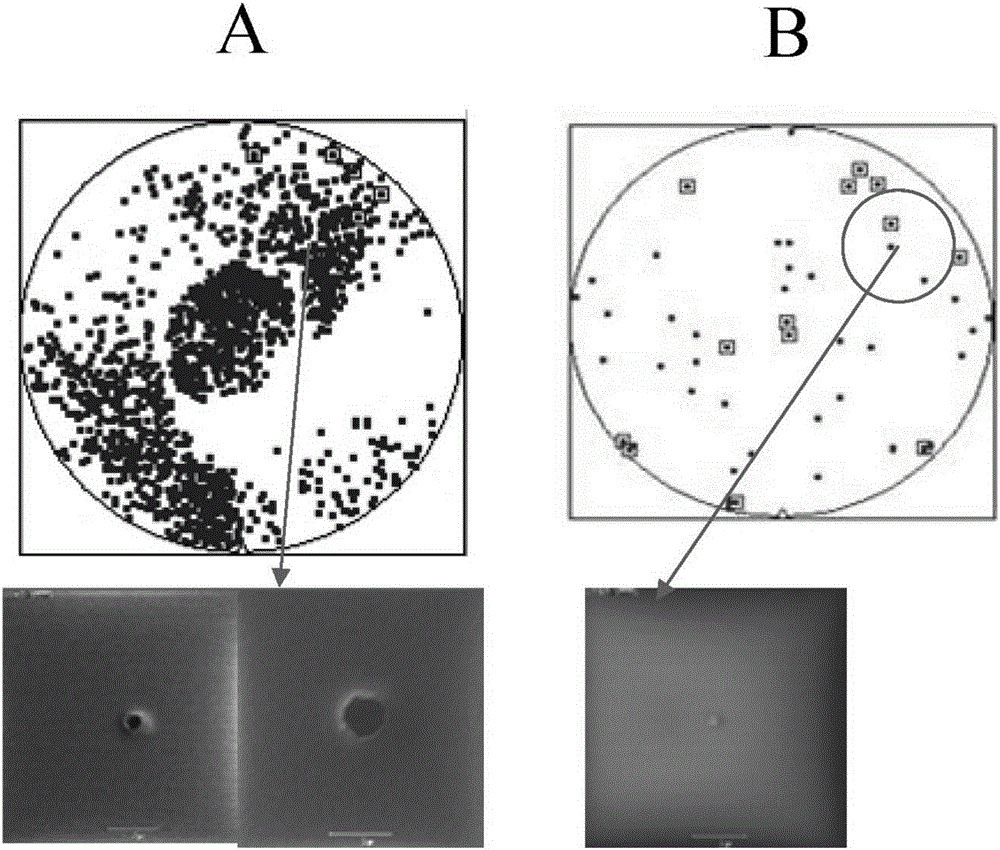

[0029] The whole process is controlled by the control module, and the processing chamber temperature is kept constant during the process. After the pretreatment, the wafers were subjected to a general silylation treatment, and the obtained wafers were subjected to a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com