Underlay-board-equipped input device

An input device and pad technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc. rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0105] (making pads)

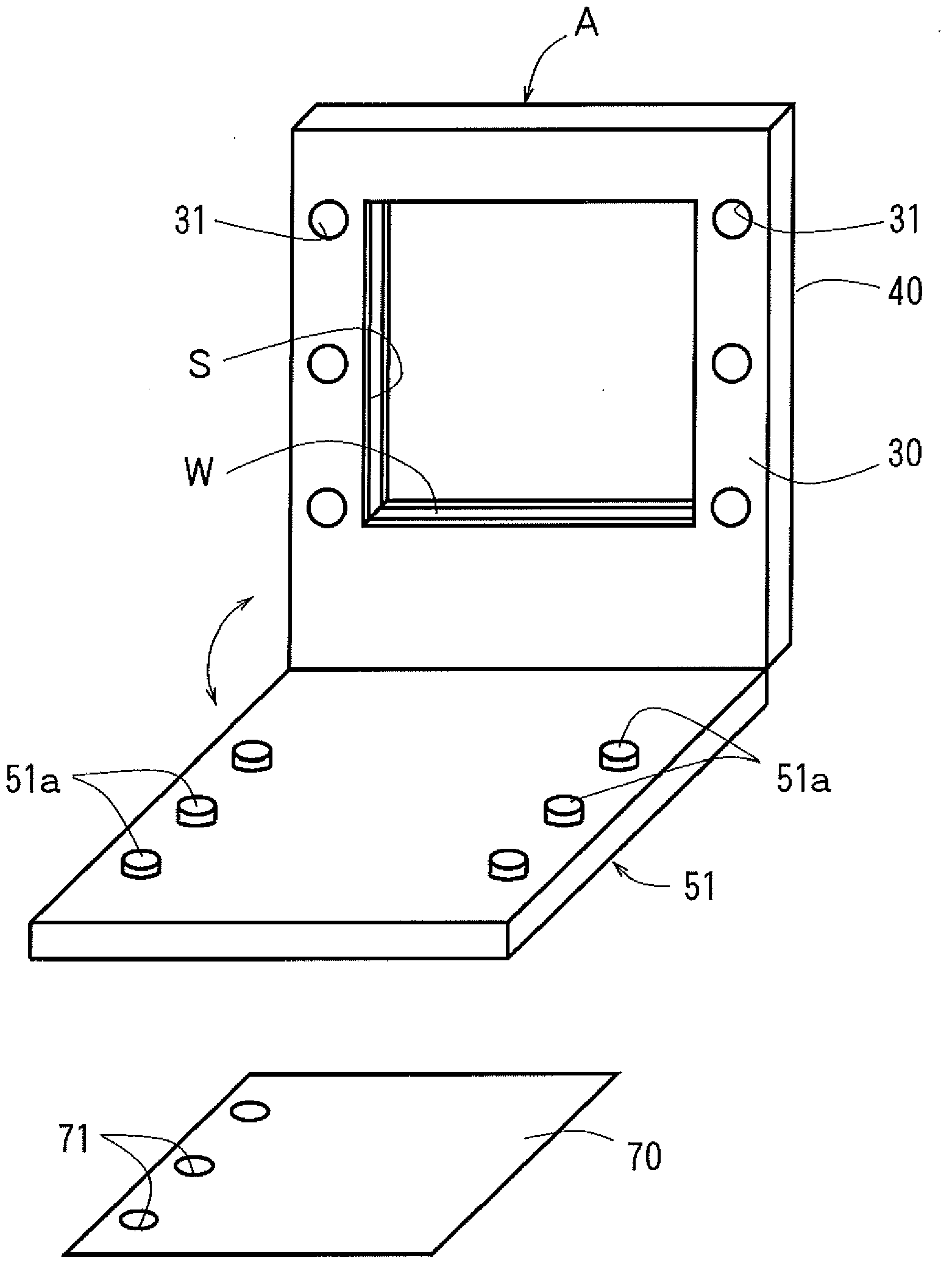

[0106] An aluminum plate was prepared as a material for forming the backing plate, and the aluminum plate was cut to produce figure 1 Shown is a backing plate formed with a plurality of cylindrical protrusions. The outer diameter of the protrusion is 5 mm, and the height is 5 mm.

[0107] (Material for forming the lower cladding layer)

[0108] Component A: 75 parts by weight of epoxy resin containing alicyclic skeleton (produced by Daicel Chemical Industry, Japan, EHPE3150).

[0109] Component B: 25 parts by weight of epoxy group-containing acrylic polymer (manufactured by NOF (NOF Corporation), MAIPNOIFG-0150M).

[0110] Component C: 4 parts by weight of a photoacid generator (manufactured by Sunafro Co., Ltd., CPI-200K).

[0111] The material for forming the under cladding layer was prepared by dissolving the above components A to C in cyclohexanone (solvent) together with 5 parts by weight of an ultraviolet absorber (manufactured by Chiba Japan C...

Embodiment 2)

[0133] (making an input device)

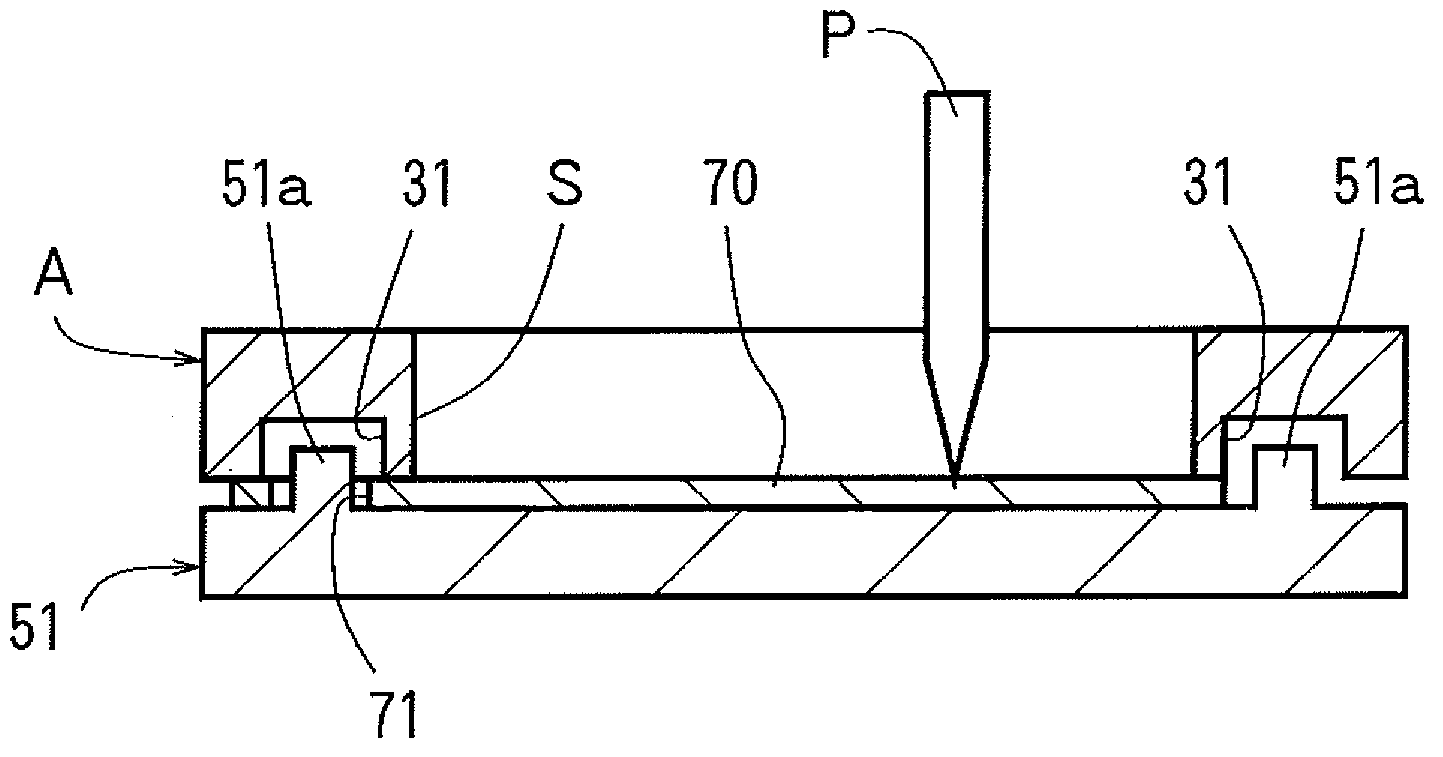

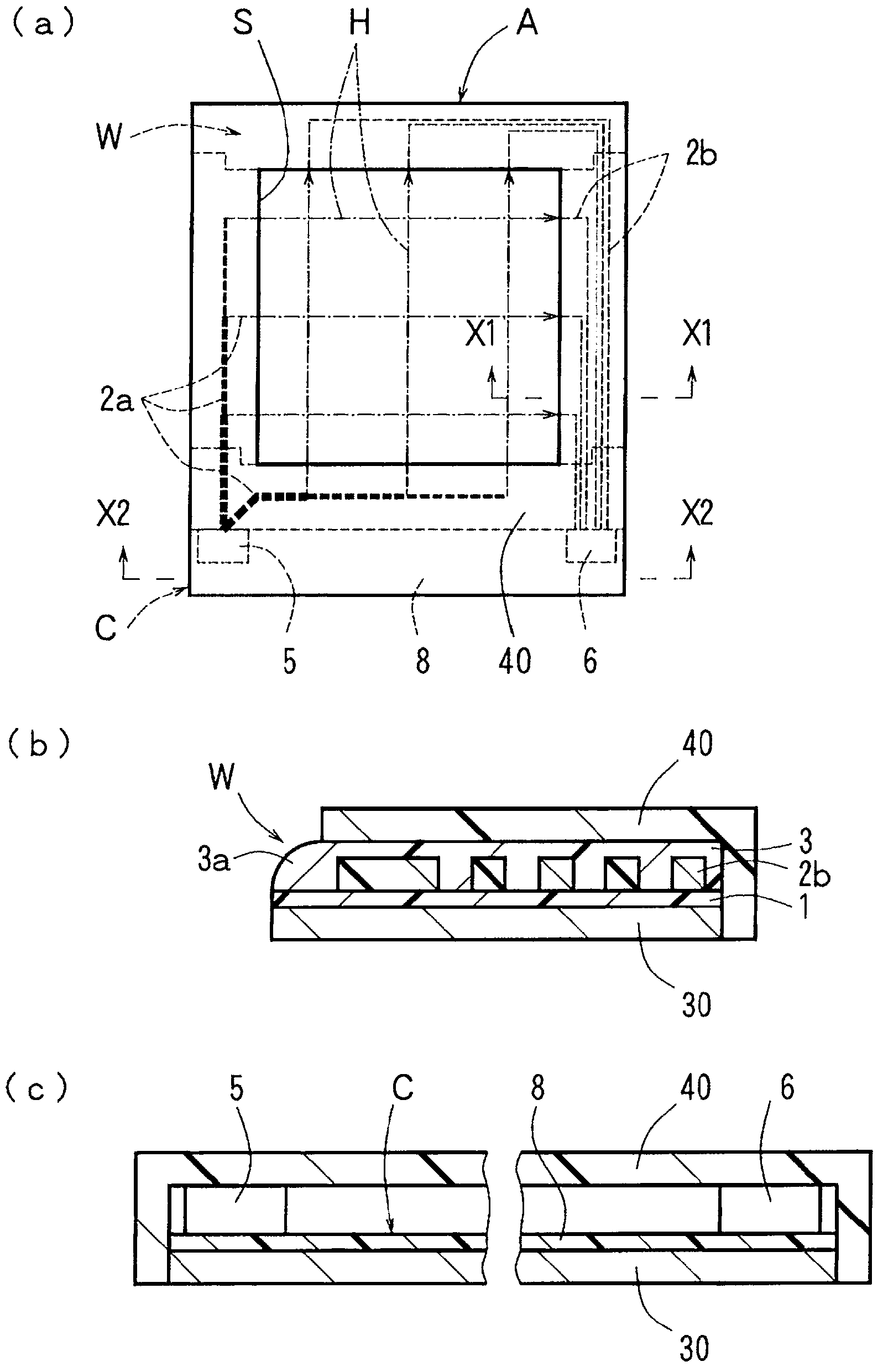

[0134] Form the same quadrangular frame-shaped holding plate as in the above-mentioned embodiment 1, and arrange a plurality of light-emitting diodes (produced by Sharp Corporation, GL4800E0000F) side by side on one of the opposite sides of the periphery of the hollow part for input. A plurality of photodiodes (manufactured by Sharp, PD411PI2E00P) are arranged side by side on the other of the two opposing sides of the periphery of the hollow portion. In addition, similarly to the above-mentioned Example 1, a CMOS driver CPU, a quartz resonator, a wireless module, two coin-shaped lithium batteries, etc. were mounted on a circuit board to manufacture a control part, and the control part was fixed on the above-mentioned holding plate. . Here, the aforementioned light-emitting diodes, photodiodes, and control components are covered with a rectangular frame-shaped stainless steel protection plate (thickness: 0.5mm) to obtain Figure 18 input devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com