One-dimensional photonic crystal optical micro-cavity based on waveguide comprising low-refractive-index cores

A technology of one-dimensional photonic crystal and low refractive index, which is applied in the field of one-dimensional photonic crystal optical microcavity, can solve the problem of large size of two-dimensional photonic crystal device, and achieve the effect of compact size, simple design structure, convenient and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

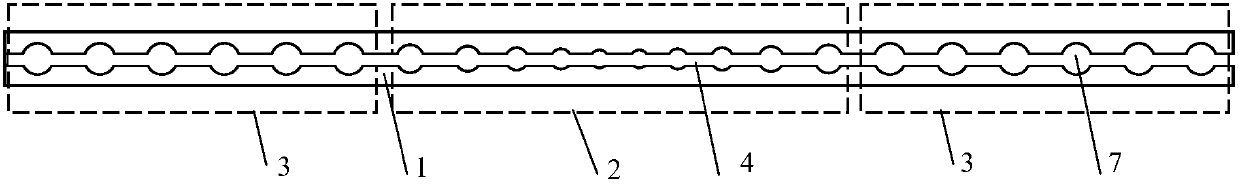

[0036] like figure 1 and Figure 7 As shown, the silicon-on-insulator (SOI) material with a top silicon thickness of 280 nm and a silicon oxide buried layer of 2 μm was used. The silicon strip waveguide with a width of 500 nm and a slit width of 100 nm and a one-dimensional periodic circular hole were fabricated by dry etching of silicon. In the periodic lattice constant area, the periodic lattice of the photonic crystal is a=480nm, and the radius r=0.28a. In the graded lattice constant area, the lattice constant decreases linearly from a to the minimum lattice constant a in the center of the microcavity through 5 times. 5 =320nm, the minimum hole radius is r 5 =0.28a 5 .

[0037] The optical microcavity in the above embodiment can support the extremely small mode volume V(~ ) and high Q (>10 3 ) , the fabrication of the entire device can be completed with only one etching.

Embodiment 2

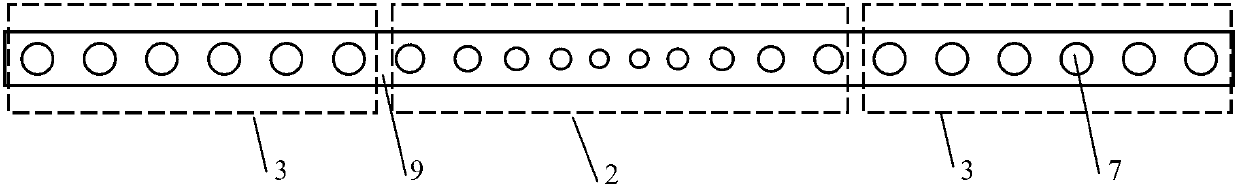

[0039] like figure 2 and Figure 8As shown, silicon-on-insulator layer with a thickness of 200nm on the top layer of silicon is selected as the material, and the horizontal slit is made by first depositing a layer of silicon dioxide with a thickness of 50nm on the silicon layer, and then depositing A silicon layer with a thickness of 200 nm is deposited or bonded on the silicon dioxide layer. After cleaning the wafer surface, perform deep ultraviolet lithography or electron beam direct writing lithography to obtain an etching mask, and dry-etch to produce silicon-silicon dioxide with a width of 500 nm and a slit width of 100 nm. —Strip waveguide with silicon three-layer structure and one-dimensional periodic circular holes. Finally, the silicon dioxide layer with low refractive index can be removed by wet etching to form an air bridge structure. In the periodic lattice constant area, the periodic lattice of the photonic crystal is a=480nm, and the radius r=0.28a. In the gra...

Embodiment 3

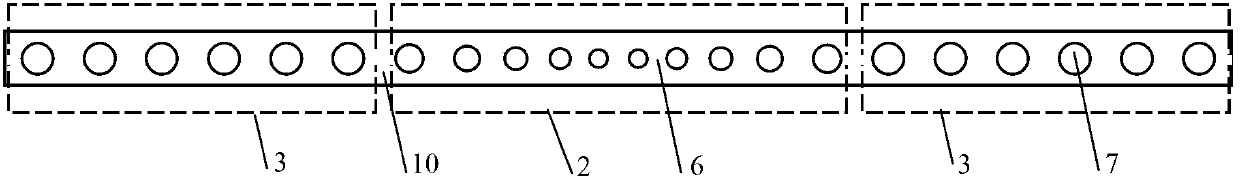

[0042] Such as image 3 and Figure 9 As shown, silicon on the insulating layer with a top silicon thickness of 250nm is selected as the material. After the wafer surface is cleaned, electron beam direct writing lithography is performed to obtain a silicon etching mask, and silicon dry etching is used to produce a 50mm wide nm, a rectangular groove with a height of 50 nm. A mask is used to deposit and fill silicon dioxide in the rectangular groove, and after a polishing process, a silicon layer with a thickness of 200 nm is deposited on the surface. After cleaning the wafer surface, perform deep ultraviolet lithography or electron beam direct writing lithography to obtain a silicon etching mask. Through silicon dry etching, a silicon strip waveguide with a width of 500 nm and a one-dimensional waveguide on the waveguide are fabricated. Periodic circular holes, and finally the silicon dioxide layer with low refractive index can be removed by wet etching to form a rectangular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com