Box type bridge static loading test rack

A static load test and box-type technology, which is applied in the testing, measuring devices, instruments, etc. of machine/structural components, can solve the problems of inconvenient lifting and assembling on site, destroying the ecological environment, and consuming a lot of steel. The effect of improving the torque resistance and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

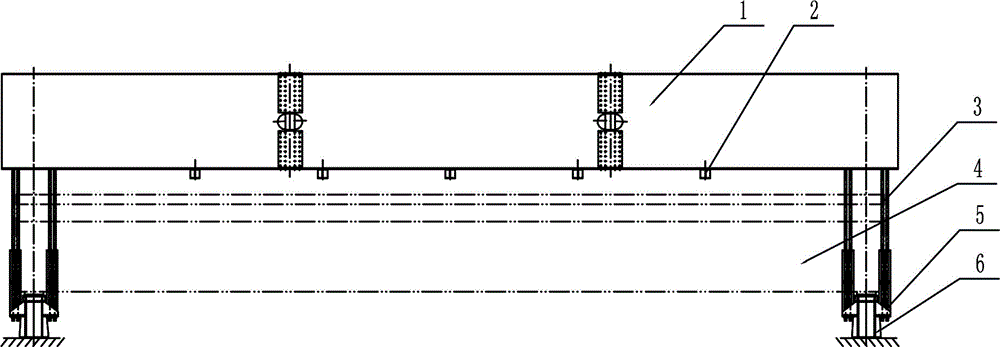

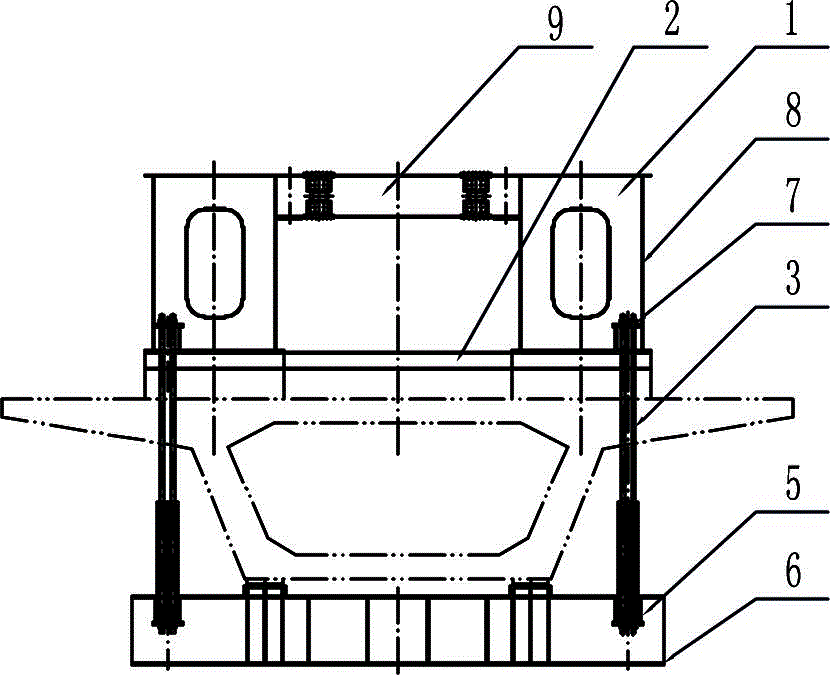

[0012] Such as figure 2 As shown, the box-type bridge static load test frame of the present invention comprises two box-type lower beams 6 and two box-type girders 1, and the ends of the two box-type girders are provided with connecting end frames 9, and the connecting ends The frame is connected with the main beam through bolts, the main beam tie rod fixing seats 7 are arranged at both ends of the main beam, the lower beam tie rod fixing seats 5 are arranged at both ends of the lower beam, and the main beam tie rod fixing seats and the lower cross beam tie rod fixing seats are passed through. There are double-ended threaded tie rods 3, which limit the maximum distance between the main beam and the lower beam through the nuts at both ends. Five loading beams 2 perpendicular to the direction of the main beam are also arranged on the lower end surface of the main beam. The length is not less than 8 distances between the outer box plates of the two girders.

[0013] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com