Method for preparing thermoelectric film by using layer by layer self-assembly

A technology of layer-by-layer self-assembly and thermoelectric thin film, which is applied in the direction of coating, metal material coating process, solid-state chemical plating, etc., can solve the problems of preparing thermoelectric thin film that have not been applied, and achieve superior performance, rich variety, and simple method operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

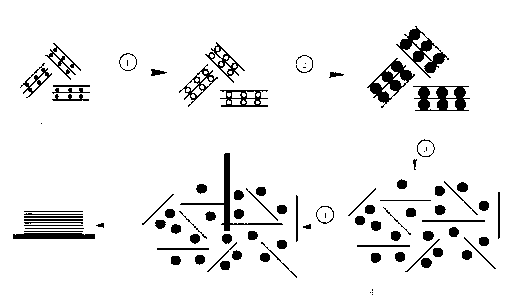

[0031] see figure 1 and figure 2 , a method for preparing a thermoelectric thin film by layer-by-layer self-assembly, comprising the steps of:

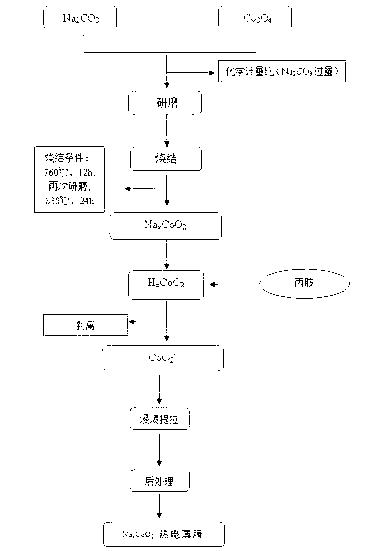

[0032] 1) Preparation of nanoflake suspensions of thermoelectric materials: first prepare the precursor materials of thermoelectric materials, namely Na x CoO 2 The synthesis of is specifically: take the stoichiometric ratio of Na 2 CO 3 and Co 3 o 4 , where Na 2 CO 3 Excessive 20% (to make up for the loss of Na at high temperature), sintering after uniform grinding, sintering conditions: 760°C, 12h, after taking out the first sintered sample, fully ground and then sintering again, sintering conditions: 830°C, 24h, Get the layered compound Na x CoO 2 ;

[0033] Proton exchange, that is, step ①: Weighing Na x CoO 2 , add 5M HCl for proton exchange, the time is 1d, after the end, centrifuge and dry to obtain the proton exchange product after acid exchange, see figure 1 ;

[0034] Ion exchange, that is, step ②: Take the p...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] see image 3 and Figure 4 A method for preparing a thermoelectric thin film by layer-by-layer self-assembly, comprising the steps of:

[0042] 1) Preparation of nanoflake suspensions of thermoelectric materials: first prepare the precursor materials of thermoelectric materials, namely Na x CoO 2 The synthesis of is identical with embodiment one;

[0043] Proton exchange, that is, step 1.: same as Example 1;

[0044] Ion exchange, i.e. step 2.: same as Example 1;

[0045] Stripping, that is, step 3.: same as Example 1;

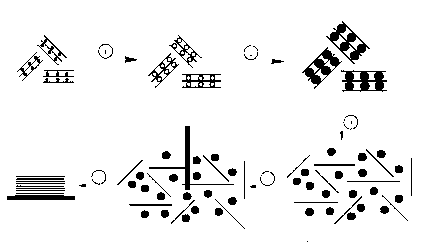

[0046] Ca 2+ Doping, that is, step ⑤: centrifuge the suspension of the stripped product in step ③, take the supernatant, and add Ca 2+ , to obtain a well-mixed Ca 2+ Doped with Na x CoO 2 solution, see image 3 ;

[0047] 2) Select the substrate, which is the same as in Embodiment 1;

[0048] 3) Self-assembly to form a thermoelectric film:

[0049] Self-as...

Embodiment 3

[0051] This embodiment is basically the same as the previous embodiment, and the special features are:

[0052] see Figure 5 and Figure 6 A method for preparing a thermoelectric thin film by layer-by-layer self-assembly, comprising the steps of:

[0053] 1) Preparation of nanoflake suspensions of thermoelectric materials: first prepare the precursor materials of thermoelectric materials, namely Na x CoO 2 The synthesis of is identical with embodiment one;

[0054] Proton exchange, that is, step 1.: same as Example 1;

[0055] Ion exchange, i.e. step 2.: same as Example 1;

[0056] Stripping, that is, step 3.: same as Example 1;

[0057] Ag + Doping, that is, step ⑦: centrifuge the suspension of the stripped product in step ③, take the supernatant, and add Ag + , to get a homogeneously mixed Ag + Doped with Na x CoO 2 solution, see Figure 5 ;

[0058] 2) Select the substrate, which is the same as in Embodiment 1;

[0059] 3) Self-assembly to form a thermoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com