Preparation method of (211) preferred orientation Mo film

A technology of preferred orientation and thin film, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of large difference in mechanical and optoelectronic properties of Mo thin film, and achieve large-area film uniformity and resistance. The effect of low rate and less internal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

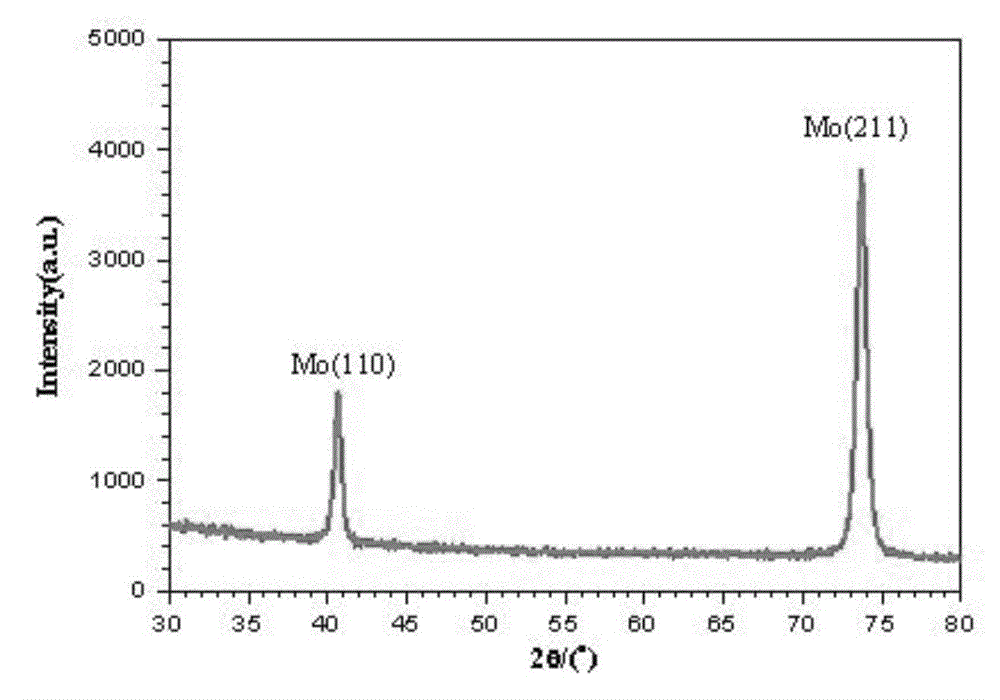

[0030] Example 1: An effective preparation method of a (211) preferentially oriented Mo thin film, the specific steps are:

[0031] (1) Clean the substrate:

[0032] The substrate (soda-lime glass, stainless steel or titanium alloy) was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min, then dried with nitrogen and placed in a sputtering vacuum chamber.

[0033] (2) Sputtering Mo film:

[0034] Install a high-purity Mo target (purity up to 99.99%) on the magnetron sputtering target gun, adjust the distance between the sputtering target gun and the substrate to be 50 mm, and pump the background vacuum to less than 3.0 × 10 -4 Pa, feed 99.995% high-purity argon to a pressure of 0.15 Pa, adjust the sputtering power to 5 W / cm 2 . After the glow stabilized, the target was pre-sputtered for 10 min to remove surface contamination, and then the film was deposited. The deposition was stopped after 20 min, and a Mo thin film with (211) preferred orientation...

Embodiment 2

[0037] Embodiment 2: An effective preparation method of a (211) preferentially oriented Mo thin film, the specific steps are:

[0038] (1) Clean the substrate:

[0039] The substrate (soda-lime glass, stainless steel or titanium alloy) was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min, then dried with nitrogen and placed in a sputtering vacuum chamber.

[0040] (2) Sputtering Mo film:

[0041] Install a high-purity Mo target (purity up to 99.99%) on the magnetron sputtering target gun, adjust the distance between the sputtering target gun and the substrate to be 50 mm, and pump the background vacuum to less than 3.0 × 10 -4 Pa, feed 99.995% high-purity argon to a pressure of 0.15 Pa, adjust the sputtering power to 5 W / cm 2 . After the glow stabilized, the target was pre-sputtered for 10 min to remove surface contamination, and then the film was deposited and stopped after 30 min to obtain a Mo film with (211) preferred orientation.

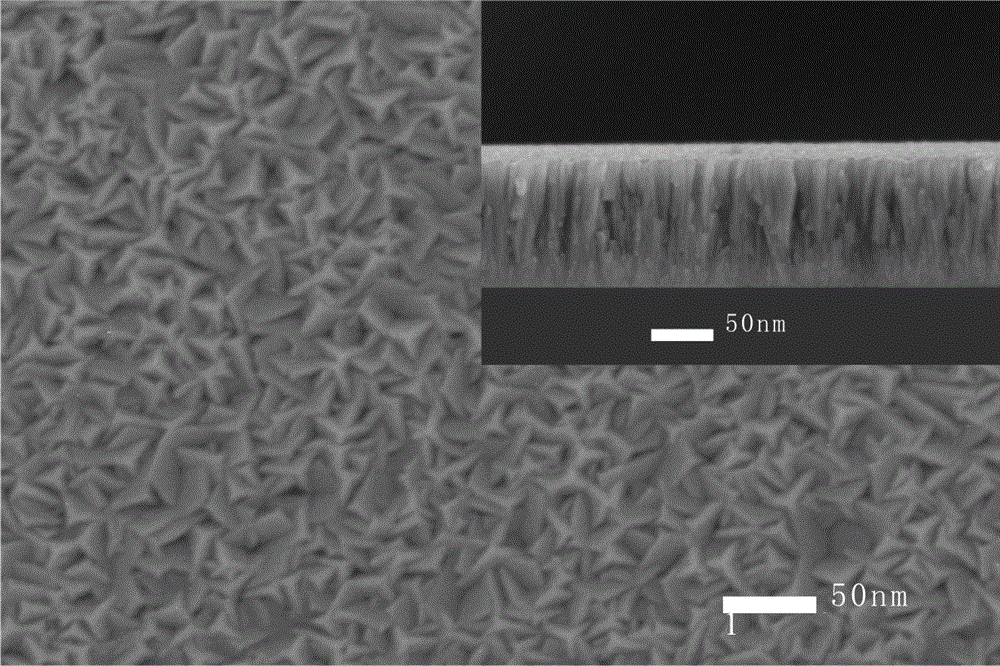

[0042] Th...

Embodiment 3

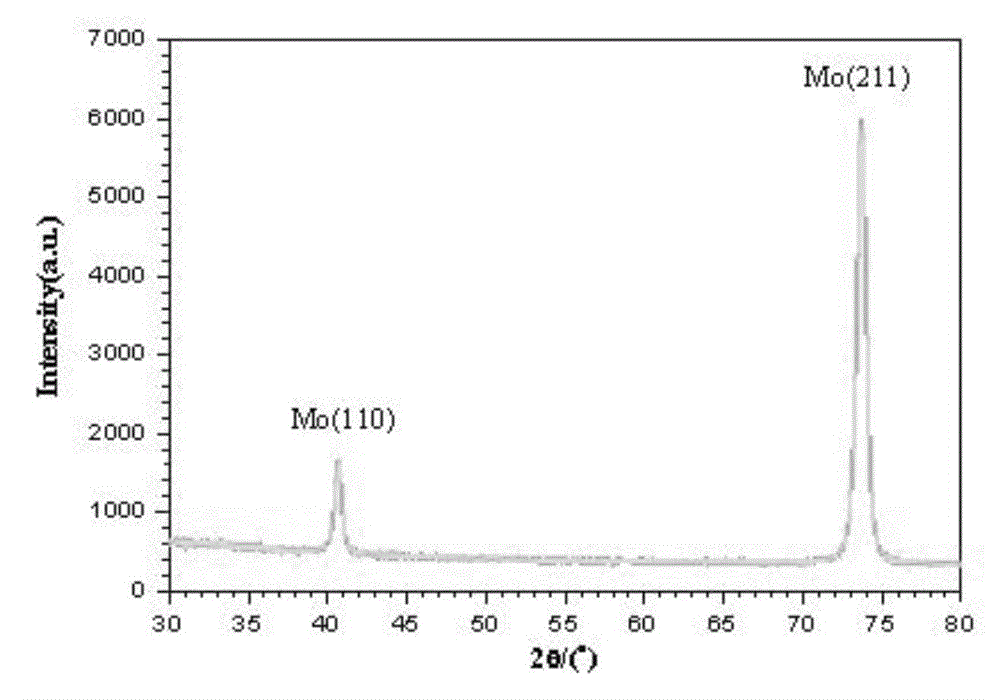

[0044] Embodiment 3: An effective preparation method of a (211) preferentially oriented Mo thin film, the specific steps are:

[0045] (1) Clean the substrate:

[0046] The substrate (soda-lime glass, stainless steel or titanium alloy) was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 min, then dried with nitrogen and placed in a sputtering vacuum chamber.

[0047] (2) Sputtering Mo film:

[0048] Install a high-purity Mo target (purity up to 99.99%) on the magnetron sputtering target gun, adjust the distance between the sputtering target gun and the substrate to be 50 mm, and pump the background vacuum to less than 3.0 × 10 -4 Pa, feed 99.995% high-purity argon to a pressure of 0.15 Pa, adjust the sputtering power to 5 W / cm 2 . After the glow stabilized, the target was pre-sputtered for 10 min to remove surface contamination, and then the film was deposited and stopped after 40 min to obtain a Mo film with (211) preferred orientation.

[0049]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com