Low-temperature vulcanized masterbatch and preparation method thereof

A vulcanized masterbatch, low temperature technology, applied in the field of rubber, can solve the problems of low crosslinking density, highly toxic vulcanized glue, tires can not be retreaded, etc., to achieve the effect of reducing vulcanization temperature, avoiding aging damage, and maintaining physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

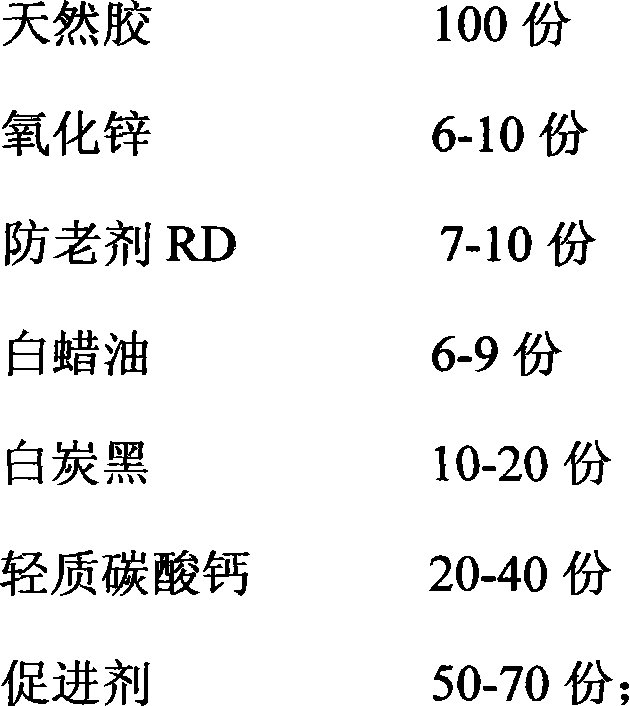

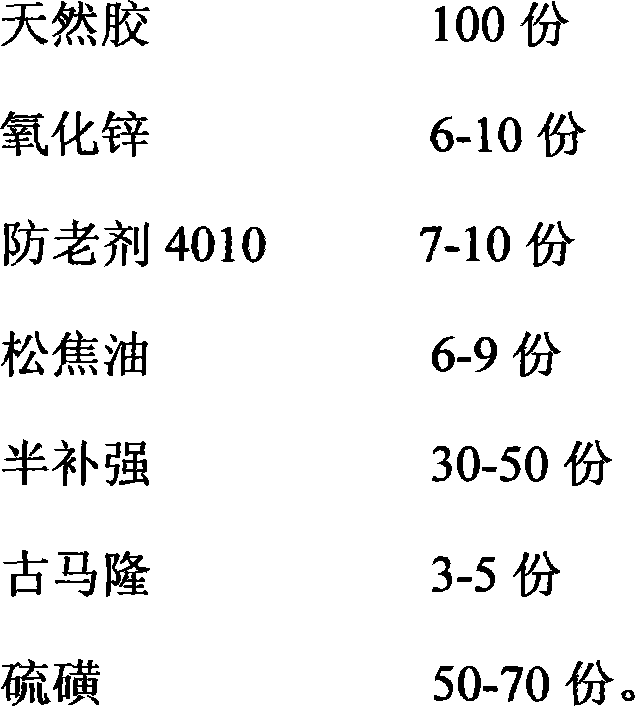

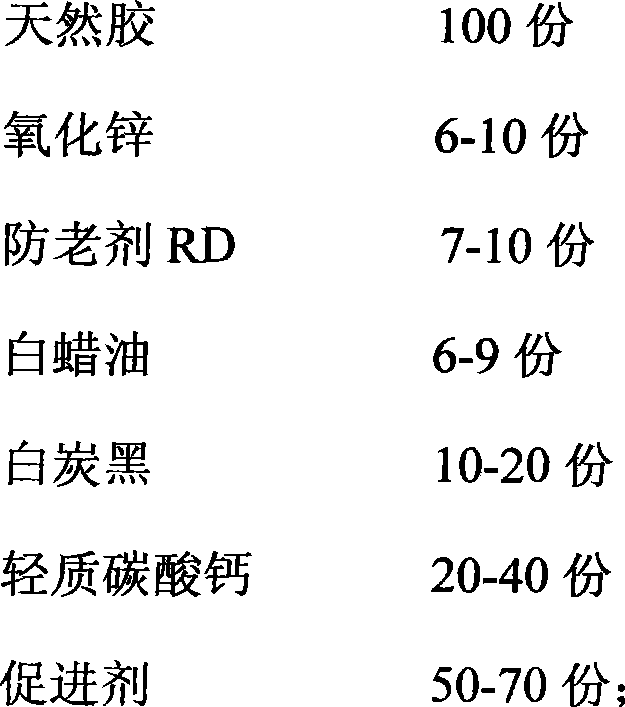

[0023] Take 15 parts by weight of high-temperature rubber, 1 part of mixed rubber A and 1 part of mixed rubber B as raw materials for low-temperature vulcanized masterbatch, wherein the formula of mixed rubber A is 100 parts by weight of natural rubber, 6 parts of zinc oxide , 7 parts of antioxidant RD, 6 parts of white wax oil, 10 parts of white carbon black, 20 parts of light calcium carbonate, 50 parts of accelerator; the formula composition of mixed glue B is 100 parts of natural rubber, 6 parts of zinc oxide by weight , 7 parts of anti-aging agent 4010, 6 parts of pine tar, 30 parts of semi-reinforcing, 3 parts of coumarone, and 50 parts of sulfur.

[0024] In the rubber mixing machine, first add high-temperature rubber 2-4mm wrapping roll, add mixed rubber A, after it is completely eaten, adjust the roller distance to less than 1mm, and pack it twice; continue 2- 4mm wrapping roll, add mixed rubber B, after it is completely eaten, adjust the roller distance to less than ...

Embodiment 2

[0026] Take 30 parts by weight of high-temperature rubber, 1 part of mixed rubber A and 1 part of mixed rubber B as raw materials for low-temperature vulcanized masterbatch, wherein the formula of mixed rubber A is 100 parts by weight of natural rubber and 10 parts of zinc oxide , 10 parts of antioxidant RD, 9 parts of white wax oil, 20 parts of white carbon black, 40 parts of light calcium carbonate, 70 parts of accelerator; the formula composition of mixed rubber B is 100 parts of natural rubber and 10 parts of zinc oxide by weight , 10 parts of anti-aging agent 4010, 9 parts of pine tar, 50 parts of semi-reinforcing, 5 parts of coumarone, and 70 parts of sulfur.

[0027] The specific operation is the same as in Example 1, and the low-temperature vulcanization masterbatch can be obtained for future use.

Embodiment 3

[0029] Take 20 parts by weight of high-temperature rubber, 1 part of mixed rubber A and 1 part of mixed rubber B as raw materials for low-temperature vulcanized masterbatch, wherein the formula of mixed rubber A is 100 parts by weight of natural rubber and 7 parts of zinc oxide , 8 parts of antioxidant RD, 7 parts of white wax oil, 15 parts of white carbon black, 25 parts of light calcium carbonate, 50 parts of accelerator; the formula composition of mixed rubber B is 100 parts of natural rubber, 8 parts of zinc oxide by weight , 8 parts of anti-aging agent 4010, 7 parts of pine tar, 40 parts of semi-reinforcing, 4 parts of coumarone, and 60 parts of sulfur.

[0030] The specific operation is the same as in Example 1, and the low-temperature vulcanization masterbatch can be obtained for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com