Methyl nitrite recovery method during CO coupling dimethyl oxalate synthesis process

A technology of methyl nitrite and reflux ratio, applied in the directions of nitrite preparation, organic chemistry, etc., can solve the problem of not providing methyl nitrite recovery and other problems, and achieve the effects of reducing loss, improving utilization rate, and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

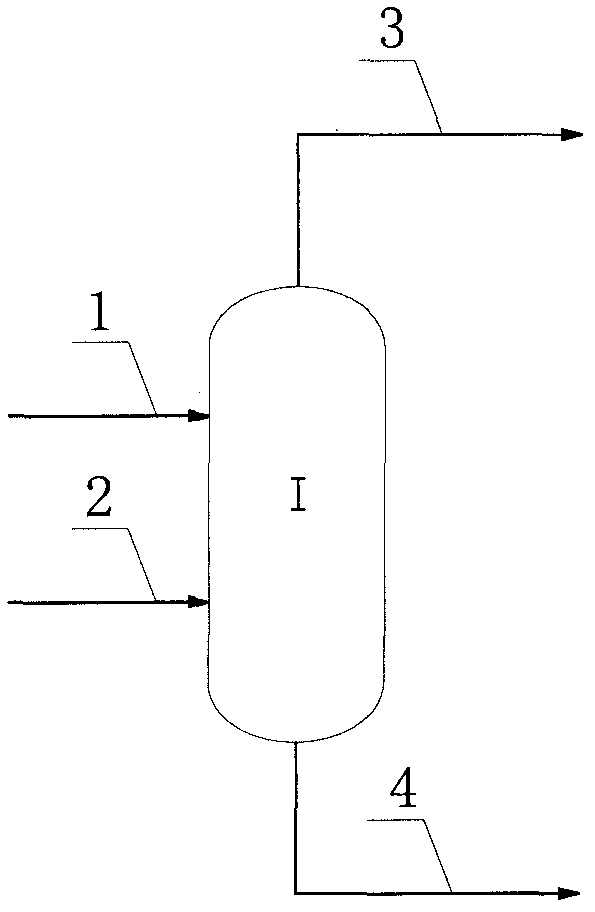

[0026] The number of rectifying tower I trays is 15, and the gas phase output of regeneration tower is that stream 1 is passed into the upper middle part of rectifying tower, promptly enters rectifying tower I by the 4th plate, and stream 1 feed temperature is 40 ℃; The noncondensable gas discharged from the chemical reactor is absorbed by the tail gas absorption tower, and the material in the bottom of the tower is a liquid stream 2, and the liquid stream 2 is passed into the middle and lower part of the rectification tower, that is, enters the rectification tower 1 by the 6th plate, and the stream 2 Feed temperature 30°C. The temperature at the top of the tower is 38°C, the temperature at the bottom of the tower is 94°C, the pressure at the tower is 250kPa, and the reflux ratio is 2. The top of the tower is separated to obtain a stream 3 containing methyl nitrite, and the tower still obtains a stream 4 containing methanol and waste water.

[0027] The condenser load per ton...

Embodiment 2

[0032] As in Example 1, the difference is that the gas phase discharge of the regeneration tower is that stream 1 enters the upper middle part of rectification tower 1, that is, enters rectification tower 1 from the third block, and the feed temperature is 43 ° C; liquid stream 2 enters rectification The middle and lower part of the tower enters the rectification tower I from the 10th plate, and the feed temperature is 22°C. The temperature at the top of the tower is 14°C, the temperature at the bottom of the tower is 90°C, the pressure at the tower is 250kPa, and the reflux ratio is 0.3.

[0033] The condenser load per ton of methyl nitrite recovered is 0.15MW, and the reboiler load is 0.43MW. The recovery of methyl nitrite was 75%. Supplement nitric oxide at 30 kg / t ethylene glycol.

[0034] The molar percentages of the stream components are shown in Table 2.

[0035] Table 2

[0036] components

Embodiment 3

[0038] As embodiment 2, difference is that the plate number of rectifying tower 1 is 30, and stream 1 enters rectifying tower by the 5th plate, and stream 2 enters rectifying tower by the 20th plate. The temperature at the top of the tower is 18°C, the temperature at the bottom of the tower is 92°C, the pressure at the tower is 250kPa, and the reflux ratio is 0.5.

[0039]The condenser load per ton of methyl nitrite recovered is 0.20MW, and the reboiler load is 0.44MW. The recovery rate of methyl nitrite was 95%. Supplement nitric oxide at 4 kg / t ethylene glycol.

[0040] The molar percentages of the stream components are shown in Table 3.

[0041] table 3

[0042] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com