Preparation method of silica micropowder-carbon composite raw material used for smelting industrial silicon

A silicon micropowder and carbon composite technology, which is applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as disposal, and achieve the effects of reducing production costs, reducing production costs, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

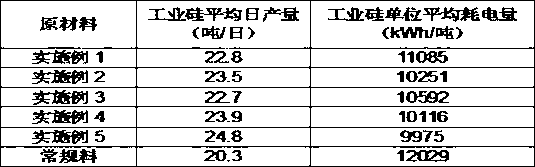

Embodiment 1

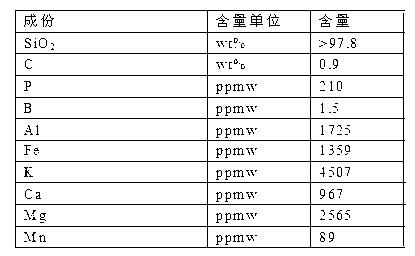

[0044] (1) Weigh 690kg of silica powder, 270kg of petroleum coke powder, and 40kg of binder.

[0045] (2) Put the silicon micropowder, petroleum coke powder and binder in the above step (1) into the mixer, and stir at a speed of 20 rpm for 50 minutes to mix the silicon micropowder, petroleum coke powder and binder evenly into mixed powder.

[0046] (3) Pack the mixed powder obtained in the above step (2) into spherical rubber moulds, and form it by isostatic pressing at 400 MPa to obtain a silicon micropowder-carbon composite block with a particle size of 90 mm, that is, silicon micropowder- Carbon composite raw material, which is spherical in shape, is used as raw material for smelting industrial silicon.

Embodiment 2

[0048] (1) Weigh 790kg of silica powder, 180kg of low-ash coal powder, and 30kg of binder.

[0049] (2) Put the silicon micropowder, low-ash coal powder and binder in the above step (1) into the mixer, and stir at a speed of 50 rpm for 30 minutes to make the silicon micropowder, low-ash coal powder and binder Mix evenly into a mixed powder.

[0050] (3) Pack the mixed powder obtained in the above step (2) into spherical rubber moulds, and form it by isostatic pressing at 500 MPa to obtain a silicon micropowder-carbon composite block with a particle size of 80mm, that is, silicon micropowder- Carbon composite raw material, which is spherical in shape, is used as raw material for smelting industrial silicon.

Embodiment 3

[0052] (1) Weigh 860kg of silica powder, 100kg of charcoal powder, and 40kg of binder.

[0053] (2) Put the silicon micropowder, charcoal powder and binder in the above step (1) into the mixer, and stir at a speed of 40 rpm for 40 minutes, so that the silicon micropowder, charcoal powder and binder are evenly mixed into a mixture Powder.

[0054] (3) Pack the mixed powder obtained in the above step (2) into spherical rubber moulds, and form it by isostatic pressing at 500 MPa to obtain a silicon micropowder-carbon composite block with a particle size of 70 mm, that is, silicon micropowder- Carbon composite raw material, which is spherical in shape, is used as raw material for smelting industrial silicon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com