Double-stand rolling method for rolling super-thick steel plate by giving consideration to both plate shape and flaw detection performance

A technology of extra-thick steel plates and double stands, which is applied in metal rolling, rolling force/roll gap control, roll speed control, etc. Problems such as small compression ratio and difficulty in plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、160

[0014] Embodiment 1, 160mm Q345B

[0015] Billet size: 400*2000*2800mm

[0016] Steel plate size: 160*2000*6800mm

[0017] Rough rolling and direct longitudinal rolling, the maximum reduction in a single pass is 38mm, the maximum reduction rate is 15.5%, and the rolling speed is 2m / s;

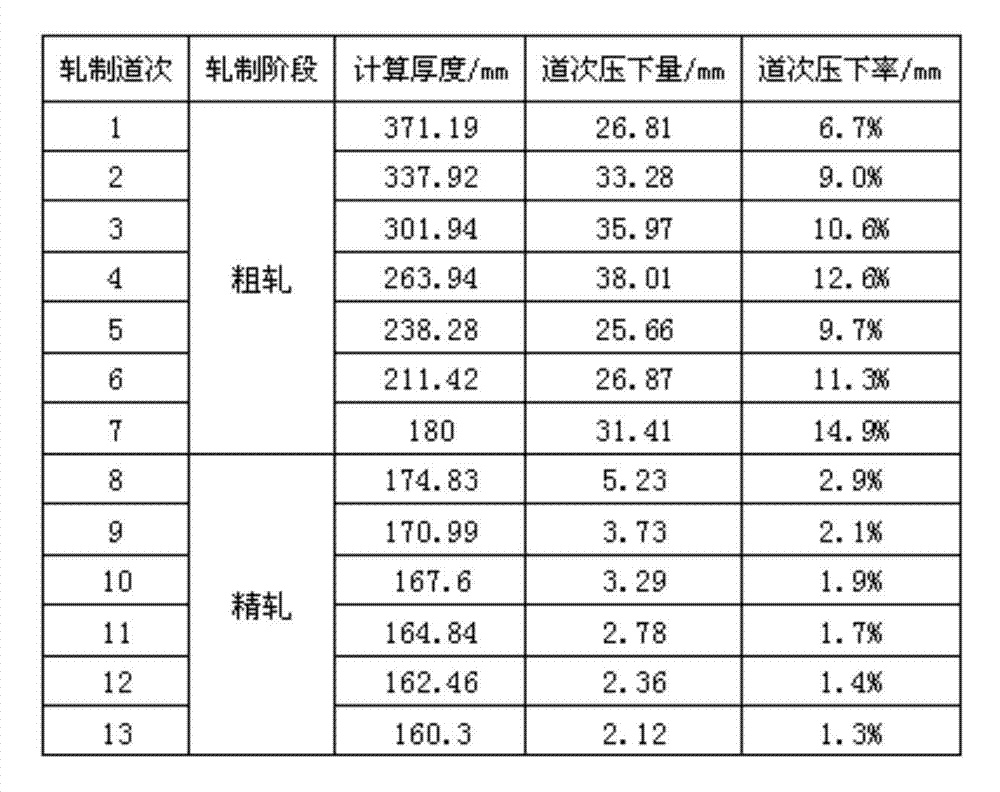

[0018] The temperature control thickness is 180mm, the finish rolling is 6 passes, the final pass reduction is 2.1mm, and the rolling speed is 4m / s. The detailed rolling procedure is shown in Table 1:

[0019] Table 1: 160mmQ345B rolling schedule

[0020]

Embodiment 2、170

[0021] Embodiment 2, 170mm Q345B

[0022] Billet size: 400*1800*3700mm

[0023] Steel plate size: 170*2000*4700-12000mm

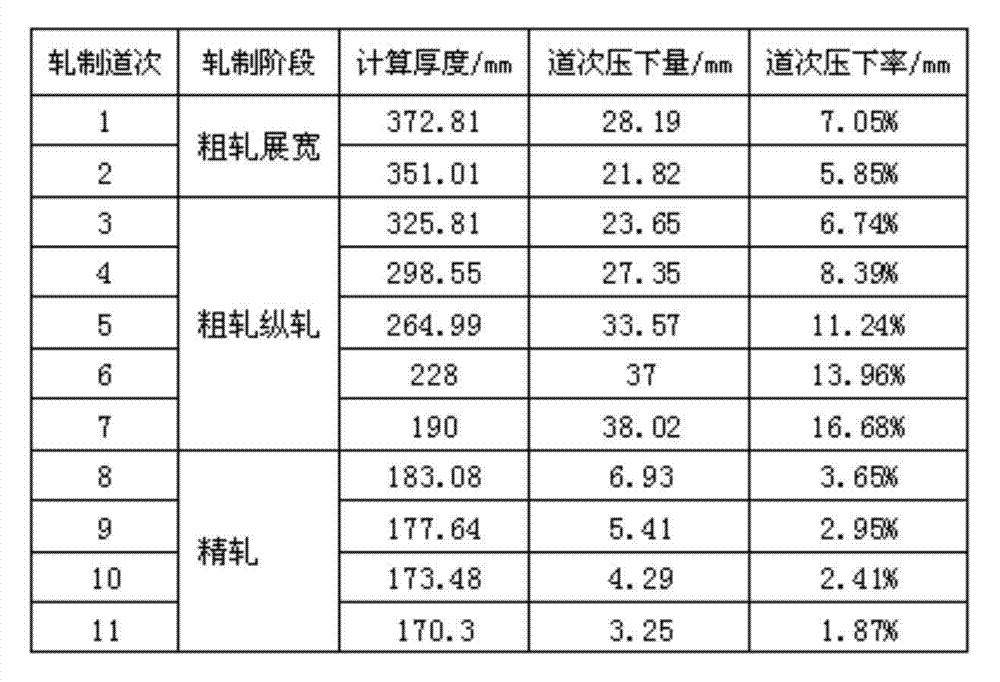

[0024] Rough rolling is first carried out with two passes of widening rolling, followed by longitudinal rolling. The maximum reduction in a single pass is 38mm, the maximum reduction rate is 16.7%, and the rolling speed is 1.5m / s;

[0025] Temperature control thickness 190mm, rolling 4 passes, final pass reduction 3.8mm, rolling speed 3.5m / s. The detailed rolling procedure is shown in Table 2:

[0026] Table 2: 170mmQ345B rolling schedule

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com