Treatment method for waste gas discharged from sewage farm

A technology of sewage treatment plant and treatment method, which is applied in the field of waste gas treatment of sewage treatment plant biochemical treatment equipment and biochemical aeration sewage treatment equipment, and can solve problems such as unstable operation and large-scale adsorption equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

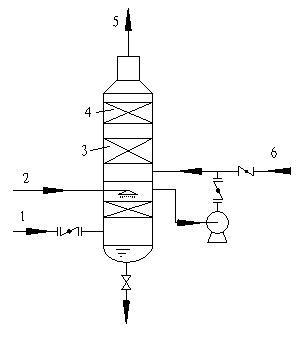

[0020] The exhaust gas from the activated sludge aeration tank in the sewage treatment plant of an oil refinery contains 20mg / m sulfide 3 About, hydrocarbons 2~150 mg / m 3 About (normal value is 10 mg / m 3 Below, it will reach 100 mg / m under abnormal working conditions 3 around), the flow rate is 20000Nm 3 / h or so. use as figure 1 In the process flow shown, industrial water is used in the spray pretreatment section, and the liquid-gas volume ratio is 1L / m 3 . The temperature of the exhaust gas after treatment in the spray pretreatment section is 28°C.

[0021] The temperature of the tail gas of the catalytic combustion device is 120°C, and the temperature of the mixed gas after mixing with the pretreated waste gas from the sewage treatment plant is 40°C, and enters the desulfurization section.

[0022] The activated carbon loaded with sodium hydroxide is used in the desulfurization section (sodium hydroxide accounts for 20% of the weight of the activated carbon by weight...

Embodiment 2

[0028] Exhaust gas from a biochemical aeration tank in a petrochemical sewage treatment plant, sulfide 5mg / m 3 around, the hydrocarbon concentration is generally 5 mg / m 3 around, sometimes more than 50 mg / m 3 about.

[0029] use as figure 1 In the process flow shown, industrial water is used in the spray pretreatment section, and the liquid-gas volume ratio is 0.5L / m 3 . The temperature of the exhaust gas after treatment in the spray pretreatment section is 25°C.

[0030] The temperature of the tail gas of the catalytic combustion device is 120°C, and the temperature of the mixed gas after mixing with the pretreated waste gas from the sewage treatment plant is 45°C, and enters the desulfurization section.

[0031] The desulfurization section uses iron oxyhydroxide desulfurizer (prepared according to the method described in CN200810112428.X Example 1), and the volume space velocity of the desulfurization section is 1000 h -1 .

[0032] The hydrocarbon concentration homog...

Embodiment 3

[0035] According to the process and treatment object of Example 1, only the spraying pretreatment section is canceled, and the temperature of the waste gas discharged from the sewage treatment plant is 31°C.

[0036] The temperature of the exhaust gas from the catalytic combustion device is 120°C, and the temperature of the mixed gas mixed with the pretreated waste gas from the sewage treatment plant is 42°C, and enters the desulfurization section.

[0037] Activated carbon loaded with sodium hydroxide is used in the desulfurization section (sodium hydroxide accounts for 20% of the weight of activated carbon by weight), and the volumetric space velocity of the desulfurization section is 5000 h -1 .

[0038] The hydrocarbon concentration homogenization section uses commercially available hydrophobic silica gel as the concentration homogenization material, and the volume space velocity of the hydrocarbon concentration homogenization section is 2000 h -1 .

[0039] The long-ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com