Method and system of using carbonated water for preserving raw milk

A carbonated water and raw milk technology, applied in the field of food science, can solve the problems of less research on cold sterilization technology, and achieve the effects of prolonging storage time, low energy consumption, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

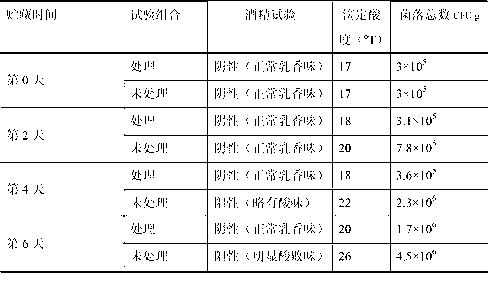

Image

Examples

Embodiment 1

[0031] A method for preserving raw milk with carbonated water, the specific steps are as follows:

[0032] ⑴Pretreatment: the CO in the cylinder 2 The gas is decompressed to 0.3MPa, and then washed through tanks containing potassium permanganate detergent with a mass concentration of 1% to 3% and sodium carbonate detergent with a mass concentration of 1% to 3%, and then adsorbed by an activated carbon tank. to complete the CO 2 Gas purification: Cool the filtered and ultraviolet sterilized water to 1-4°C, and perform vacuum degassing treatment at a vacuum degree of -0.04-0.06MPa for 0.4-2 seconds;

[0033] (2) Carbonation of water: CO 2 The gas is mixed with the sterilized and cooled water at 0.3-0.5MPa and 1-4°C. In this example, the gas-water ratio is 47g:100g to obtain carbonated water;

[0034] ⑶ Raw milk pretreatment: After collecting fresh raw milk, in order to remove oxygen and nitrogen in the raw milk and increase the mixing degree of carbonated water, the fresh raw...

Embodiment 2

[0038] A method for preserving raw milk with carbonated water, the specific steps are as follows:

[0039] ⑴Pretreatment: the CO in the cylinder 2 The gas is decompressed to 0.4MPa, and then washed through tanks containing potassium permanganate detergent with a mass concentration of 1% to 3% and sodium carbonate detergent with a mass concentration of 1% to 3%, and then adsorbed by an activated carbon tank. to complete the CO 2 Purification of gas; water is filtered, sterilized by ultraviolet rays, cooled to 1-4°C, and vacuum degassed at -0.04-0.06MPa vacuum for 0.4-2 seconds;

[0040] ⑵Water carbonation: CO 2 The gas is mixed with the sterilized and cooled water at 0.3-0.5 MPa and 1-4°C. The gas-water ratio in this example is 49g:100g to obtain carbonated water;

[0041] ⑶ Raw milk pretreatment: After collecting fresh raw milk, in order to remove oxygen and nitrogen in the raw milk and increase the mixing degree of carbonated water, the fresh raw milk is degassed under the...

Embodiment 3

[0045] A method for preserving raw milk with carbonated water, the specific steps are as follows:

[0046] ⑴Pretreatment: the CO in the cylinder 2 The gas is decompressed to 0.5MPa, and then washed through tanks containing potassium permanganate detergent with a mass concentration of 1% to 3% and sodium carbonate detergent with a mass concentration of 1% to 3%, and then adsorbed by an activated carbon tank. to complete the CO 2 Purification of gas; water is filtered, sterilized by ultraviolet rays, cooled to 1-4°C, and vacuum degassed at -0.04-0.06MPa vacuum for 0.4-2 seconds;

[0047] ⑵Water carbonation: CO 2 The gas is mixed with the sterilized and cooled water at 0.3-0.5MPa, 1-4°C to obtain a saturated solution with a gas-water volume ratio of 2.5:1-3.5:1. At this time, CO 2 The concentration is 54g / 100g water, obtains carbonated water;

[0048] ⑶ Raw milk pretreatment: After collecting fresh raw milk, in order to remove oxygen and nitrogen in the raw milk and increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com