Brake system and electromagnetic actuation device for same

A braking system, electromagnetic actuation technology, applied in the direction of brake type, energy absorption brake, asynchronous inductive clutch/brake, etc., can solve the problems of leakage, long production cycle, complex process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As required, specific embodiments of the invention will be disclosed herein. However, it should be understood that the embodiments disclosed herein are merely typical examples of the invention, which can be embodied in various forms. Therefore, specific details disclosed herein are not to be considered limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the invention in any appropriate way in practice, This includes taking various features disclosed herein and combining features that may not be expressly disclosed herein.

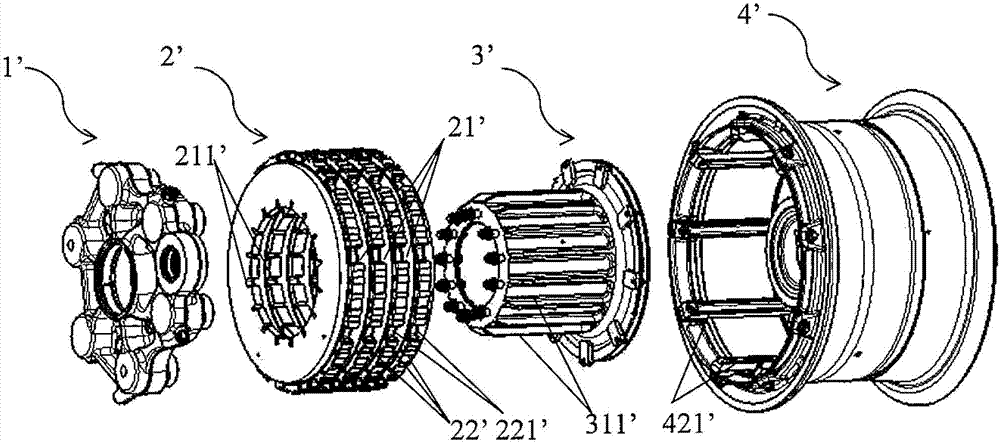

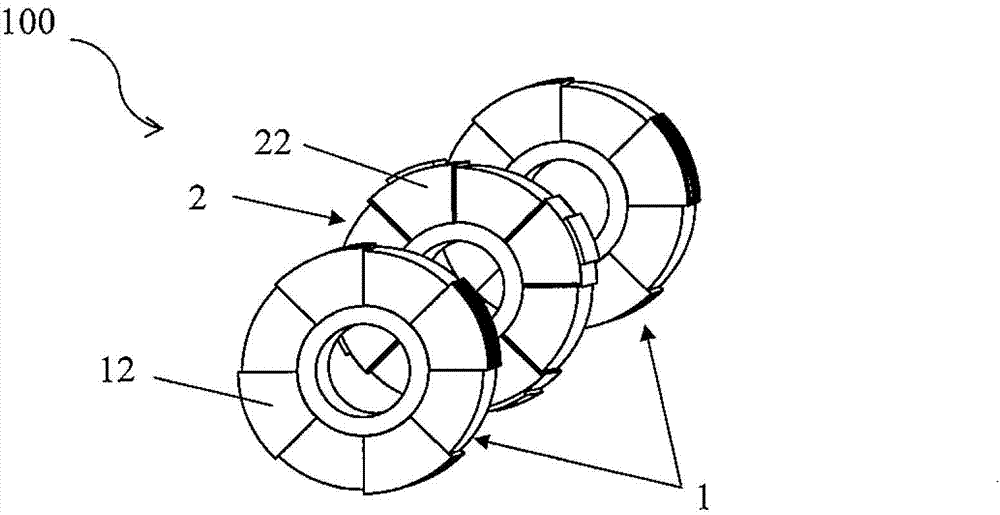

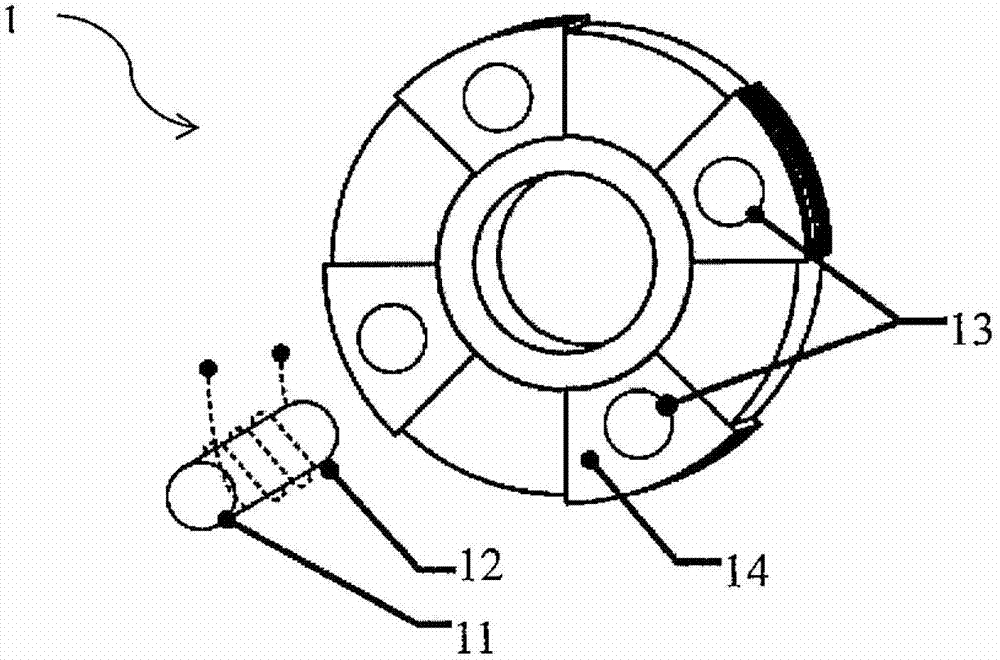

[0030] and figure 1 Compared with the mechanical parts of the traditional hydraulic brake system or electric brake system shown, the brake system according to the preferred embodiment of the present invention omits the hydraulic or electric drive actuator 1' and the brake disc 2', and introduces an improved Type electromagnetic actuator 100 (such as figure 2 shown). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com