Quantitative non-destructive testing equipment for defects in oil and casing

A non-destructive testing and practical technology, applied to measuring devices, using acoustic wave emission technology for material analysis, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem of not being able to determine the size of surface or internal defects, and not applicable to oil casing pipes Column reliability design, unable to calculate the safety and reliability of oil and casing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

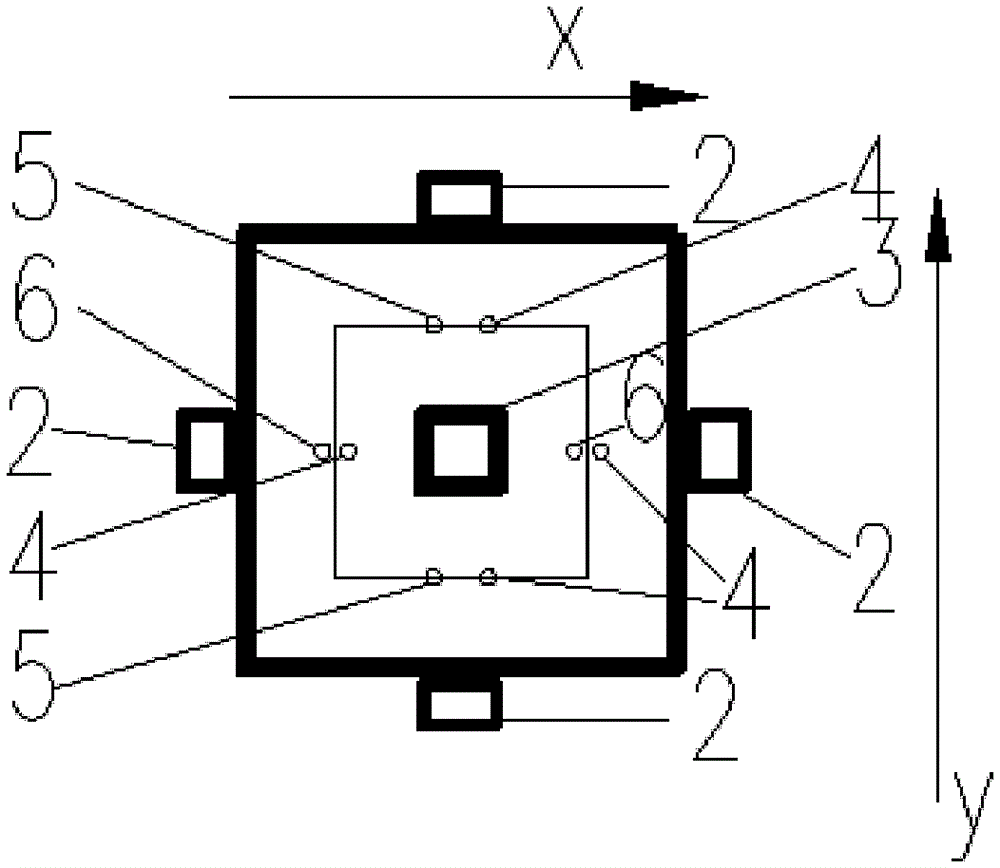

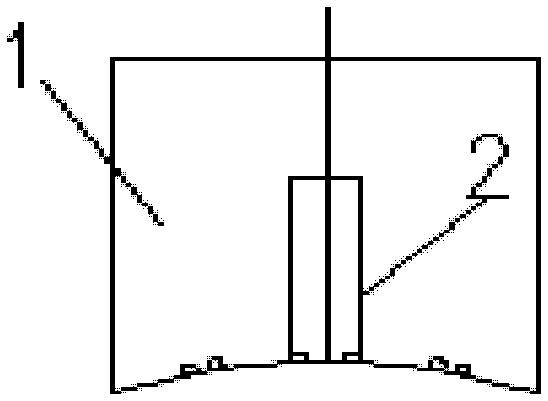

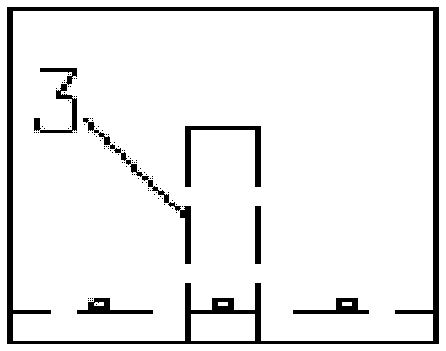

[0016] The defect quantitative non-destructive testing equipment for oil casing pipes according to the present invention is composed of a probe 7, a probe frame 12, a signal wireless transmission and signal amplification system 8, a ball 15, a stator 13, a mover 11, a bracket 10 and a roller 16;

[0017] The cylindrical stator 13 wound with copper wire is fixed on the bracket 10, three balls 15 are fixed on the inner surface of the stator 13, the cylindrical mover 11 wound with copper wire is placed on the ball 15, the mover 11 and the probe frame 12 are connected as a whole, 2-4 probes 7 are evenly installed on the inner surface of the probe frame 12 along the circumference, and the signal wireless transmission and signal amplification system 8 and the battery 14 are installed on the outer surface of the probe frame 12 and connected with the probes 7 ; The rollers 16 are placed on both sides of the bracket 10 .

[0018] The probe 7 is composed of an AC excitation signal coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com