Nondestructive testing device and method based on pipeline temperature field distribution

A non-destructive testing and testing device technology, applied in measurement devices, material defect testing, instruments, etc., can solve the problems of harmful X-rays, the influence of fluid in pipelines, high pressure danger, etc., and achieves low cost, good testing effect, and improved accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

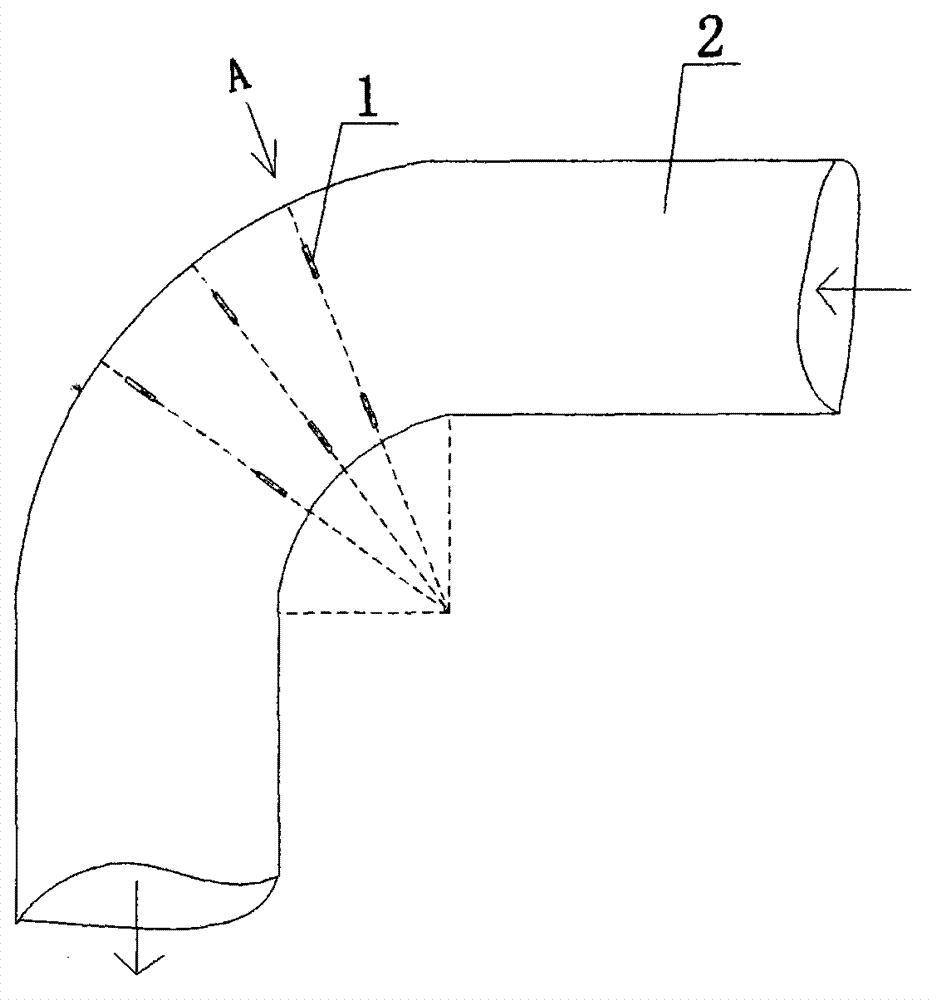

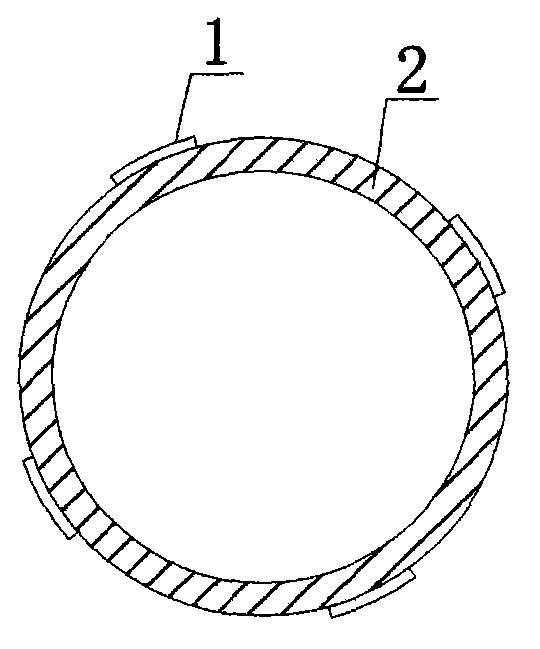

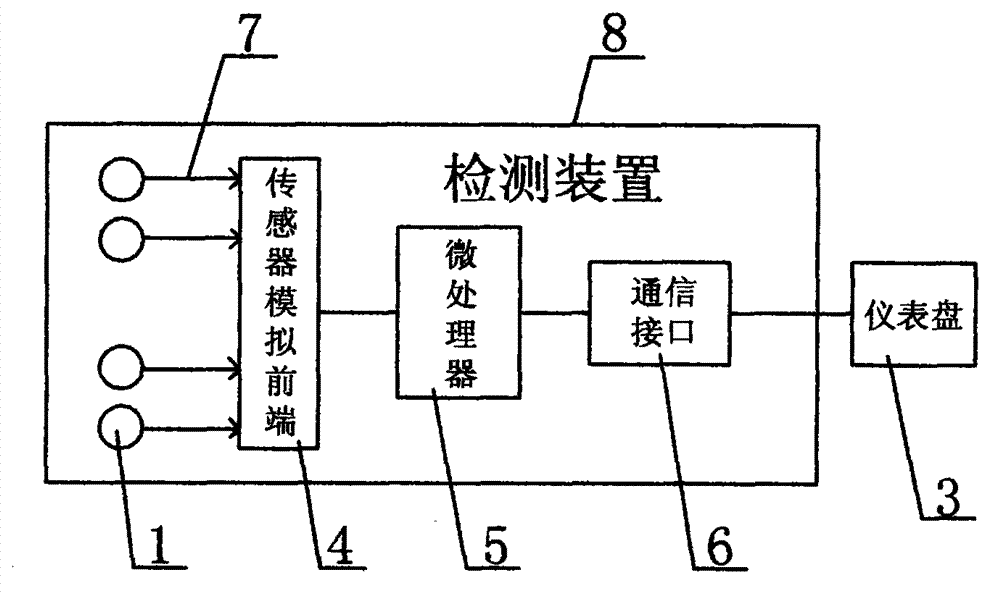

[0037] The invention proposes a non-destructive testing device based on the temperature field distribution of pipelines. It is mainly used in many fields such as chemical production, petroleum, electric power, etc. for the scour detection of bent pipes. It can realize non-contact, fast, high sensitivity and safe operation. Unique operational advantages, in the actual application process, it has a good detection effect on the detection of pipeline 2 leakage and insulation layer defects, the detection of high-temperature pressure pipe inner wall defects and the detection of partial shedding of the inner wall of pipeline 2, etc., its structure includes A detection device provided with a temperature sensor 1, such as figure 1 , figure 2 As shown, the temperature sensor 1 is set on the outer wall of the pipeline 2, and the detection device is connected to the instrument panel 3. During use, the staff can obtain accurate temperature values according to the data on the instrument ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com