Method for preparing superfine phenolic fibre

A technology of phenolic fiber and phenolic resin, which is applied in the field of preparation of ultrafine phenolic fiber and can solve the problems of preparing phenolic fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

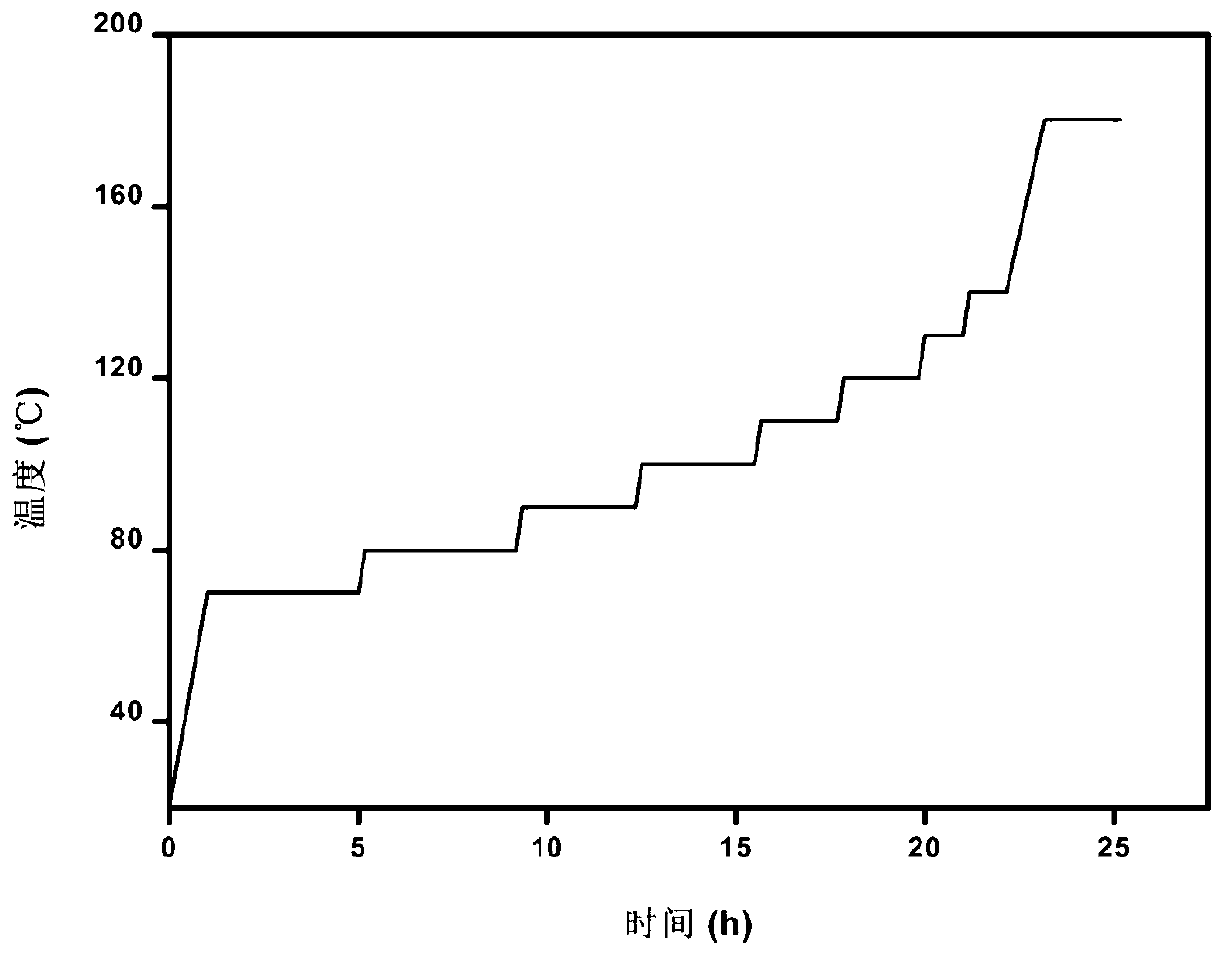

[0026] This embodiment includes the following steps:

[0027] Step 1, the commercially available low molecular weight 500w <3000 resol resin is configured as an organic solution of 20wt% resol resin, the resol resin is a thermosetting phenol resin with Mw=2000, and the solvent is ethanol;

[0028] Step 2. Add 0-1.5 wt% high molecular weight linear polymer to the solution and stir until completely dissolved. The high molecular weight linear polymer is polyvinyl butyral PVB;

[0029] Step 3: Electrospin the obtained solution to obtain superfine phenolic fiber and phenolic fiber felt. During the electrospinning process, the ambient humidity is RH35%, the temperature is 25°C, the voltage is 25kv, and the distance between the needle and the substrate is 25cm. The feed rate was 1 ml / h.

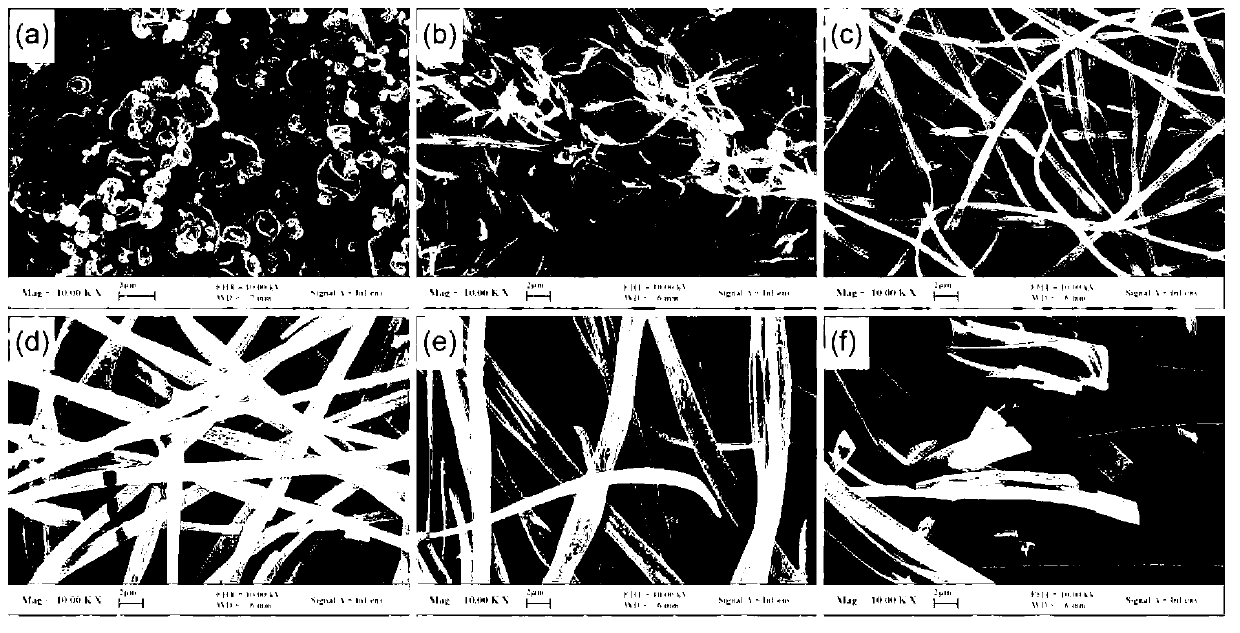

[0030] The morphology of the electrospun product is shown in Figure (1). When no polyvinyl butyral PVB is added, the product has an uneven bead structure. With the increase of PVB content, the prod...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] Step 1, the commercially available low molecular weight 500w <3000 resol resin is configured as an organic solution of 25wt% resol resin, the resol resin is a thermosetting phenol resin with Mw=2000, and the solvent is ethanol;

[0034] Step 2: Add 0.6wt% high molecular weight linear polymer to the solution and stir until completely dissolved. The high molecular weight linear polymer is polyvinyl butyral PVB

[0035]Step 3: Electrospinning the obtained solution to obtain superfine phenolic fiber and phenolic fiber felt. During the electrospinning process, electrospinning is carried out under two conditions of ambient humidity RH50% and RH30% respectively, the temperature is 25°C, and the voltage The voltage is 25kv, the distance between the needle and the substrate is 25cm, and the solution feed rate is 1ml / h.

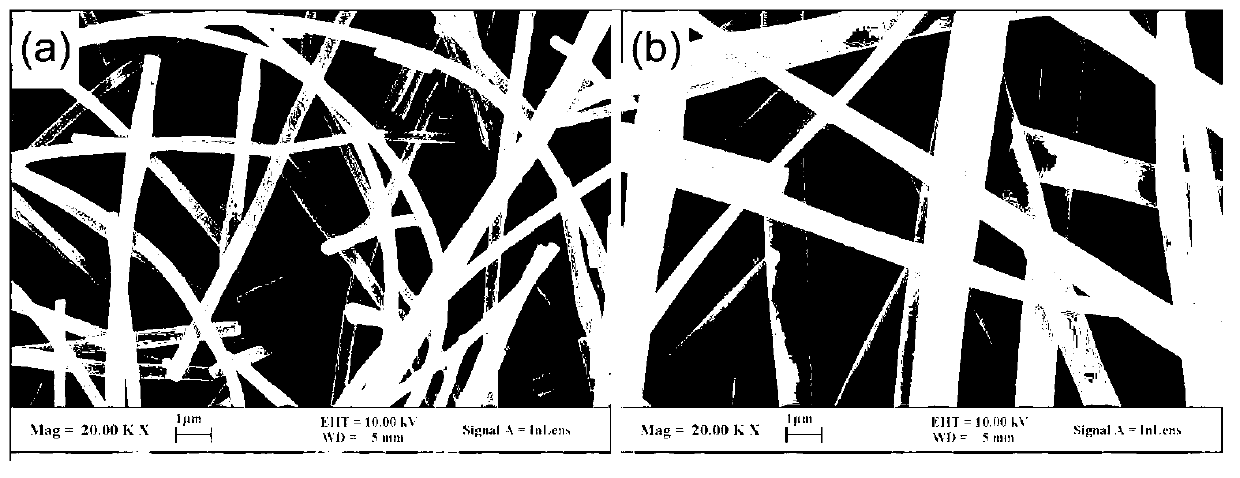

[0036] The morphology of the electrospun product is shown in the attached figure (2). It can be seen tha...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1, the commercially available low molecular weight 500w <3000 resol resin is configured as an organic solution of 25wt% resol resin, the resol resin is a thermosetting phenol resin with Mw=2000, and the solvent is a mixture of acetone, ethanol or ethanol and DMF in different volume ratios (9:1 and 7:3);

[0041] Step 2: Add 0.6wt% high molecular weight linear polymer to the solution and stir until completely dissolved. The high molecular weight linear polymer is polyvinyl butyral PVB

[0042] Step 3: Electrospinning the obtained solution to obtain superfine phenolic fiber and phenolic fiber felt, the ambient humidity is RH30%, the temperature is 25°C, the voltage is 25kv, the distance between the needle and the substrate is 25cm, and the solution feed rate is 1ml / h .

[0043] The morphology of the prepared electrospun product is shown in Figure 5 , when the solvent is acetone, the cross-section of the resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com