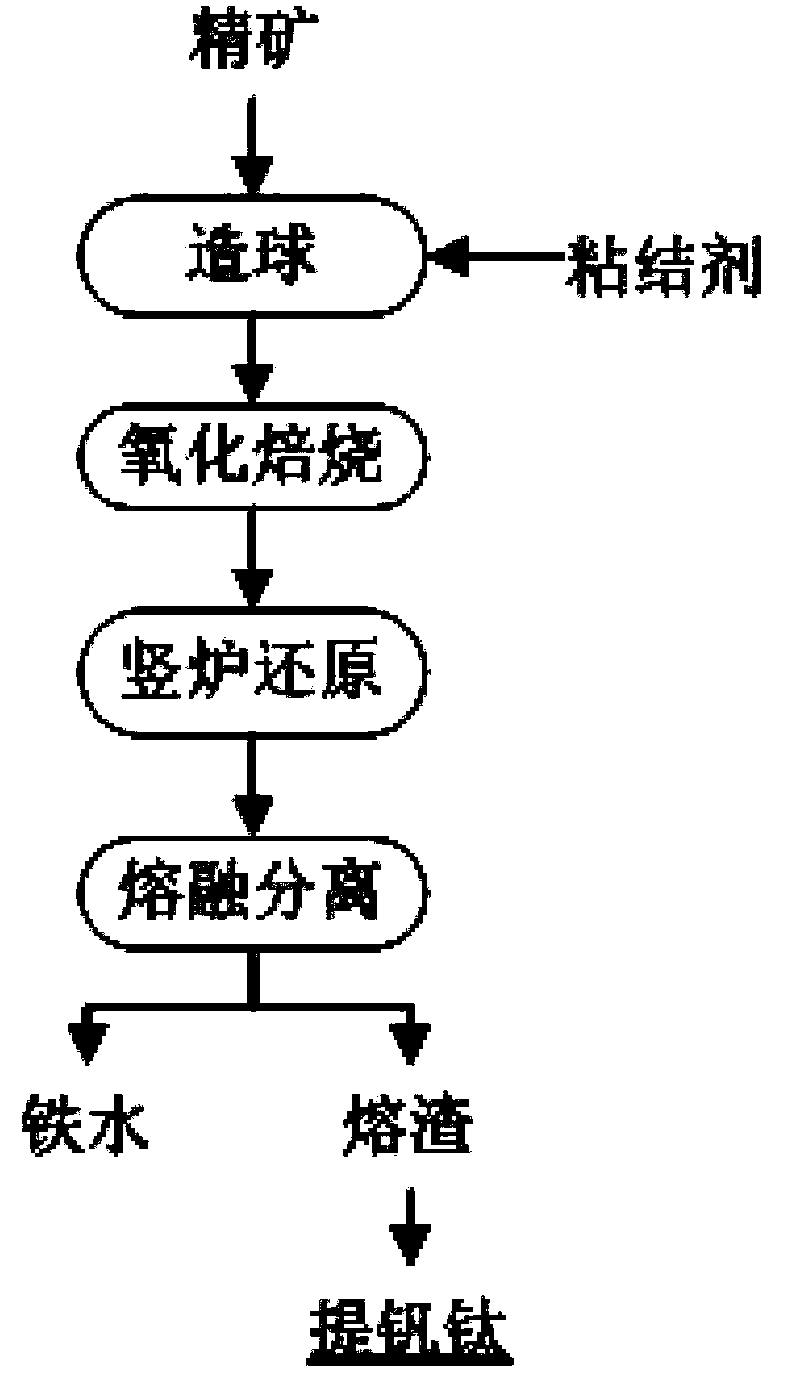

Method for comprehensively using vanadium-titanium magnetite by shaft furnace reduction and electric furnace melting

A vanadium-titanium magnetite and electric furnace technology, applied in electric furnaces, shaft furnaces, furnaces, etc., can solve the problems of rapid reduction in reducing gas temperature, unfavorable reactions, high pressure, etc., and achieve the effect of relieving the increasingly tense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Vanadium-titanium magnetite concentrate (TFe 43.2%, FeO 16.8%, V2O51.2%, TiO221.6%) with a particle size of -0.074mm accounting for 60%, mixed with a binder, and then made 10-15mm pellets, dried at 200°C for 2 hours, roasted at 1100°C for 3 hours, then loaded into the shaft furnace, reduced in the shaft furnace at 1100°C for 4.5 hours, the reducing gas pressure is 0.3MPa, and the reducing gas is H2+CO ≈92%, the molar ratio of H2 to CO is 2.8. The direct reduction product is charged into an electric furnace for melting and separation. The melting temperature is 1650°C. The melting iron element analysis is TFe 94.8%, V2O50.2%, TiO 20.06%, and the melting slag element analysis is TFe 5%, V2O52.8 %, TiO254.4%. From vanadium-titanium magnetite concentrate to melting stage, the recovery rates of iron, vanadium, and titanium are 95%, 92%, and 99%, respectively.

Embodiment 2

[0040] Example 2: Vanadium-titanium magnetite concentrate (TFe 55.9%, FeO 22.8%, V2O50.53%, TiO211.8%) with a particle size of -0.074mm accounting for 75%, mixed with a binder, and then made 10-15mm pellets, dried at 200°C for 2 hours, roasted at 1100°C for 3 hours, then loaded into the shaft furnace, reduced in the shaft furnace at 1050°C for 5.5 hours, the reducing gas pressure is 0.2MPa, and the reducing gas is H2+CO ≈90%, the molar ratio of H2 to CO is 1.6. The direct reduction product is charged into an electric furnace for melting and separation. The melting temperature is 1550℃. The melting iron element analysis is TFe94%, V2O5 0.1%, TiO2 0.05%, and the melting slag element analysis is TFe 9%, V2O5 2.2%, TiO2 52.7% . From vanadium-titanium magnetite concentrate to melting stage, the recovery rates of iron, vanadium, and titanium are 97%, 91%, and 99%, respectively.

[0041] The beneficial effects of the present invention:

[0042] (1) For blast furnace smelting, titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com