Alignment film material, alignment film and preparation method of alignment film, and liquid display device

A technology of alignment film and alignment layer, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of large investment and high equipment cost, and achieve the effect of good orientation uniformity, small investment, and increased uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

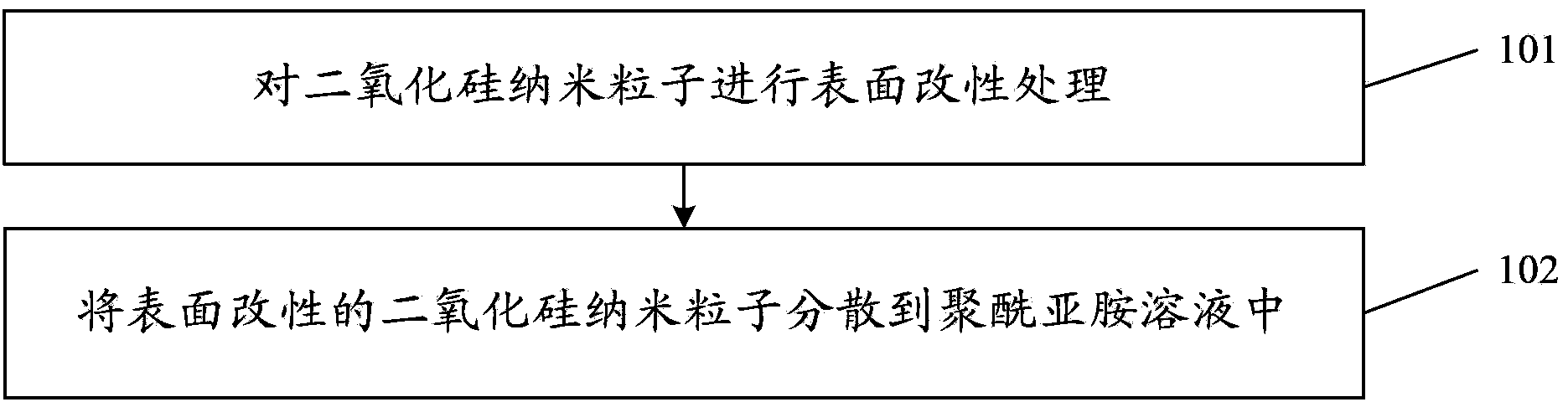

[0081] An embodiment of the present invention provides a method for manufacturing an alignment film material, such as figure 1 As shown, the method includes:

[0082] Step 101, carry out surface modification treatment on the silica nanoparticles, to eliminate or reduce the number of hydroxyl groups on the surface of the silica nanoparticles, and graft the terminal with amino groups (-NH 2 ) linear chain to obtain surface-modified silica nanoparticles;

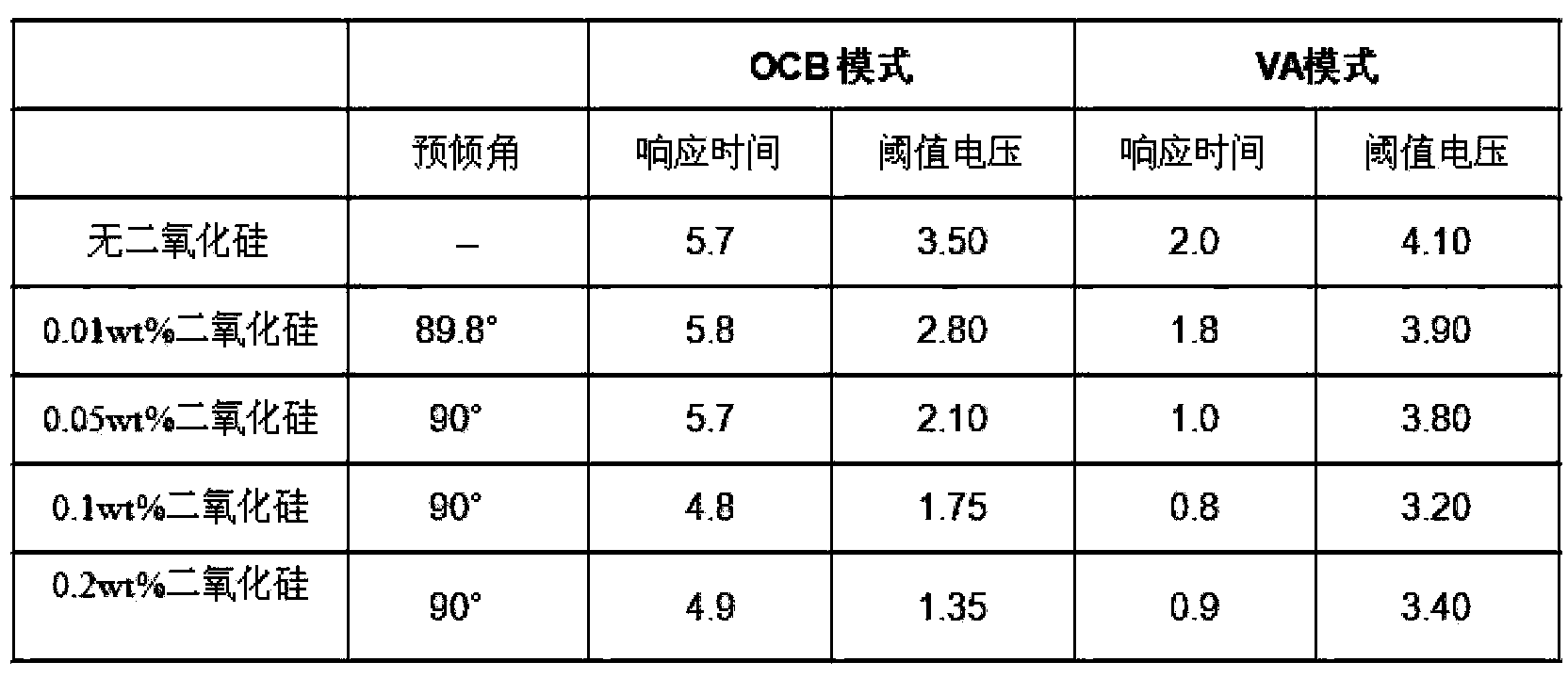

[0083] Step 102, disperse the surface-modified silica nanoparticles into the polyimide solution to prepare a mixed solution containing surface-modified silica nanoparticles and polyimide, wherein the surface-modified two The mass percentage of the silicon oxide nanoparticles relative to the polyimide is 0.01wt%-0.2wt%.

[0084] The particle size of silica nanoparticles is small, the specific surface area is large, and the surface contains hydroxyl groups, which are easy to agglomerate to form aggregate particles. In step 101...

Embodiment 2

[0120] Corresponding to the manufacturing method in Example 1, this embodiment of the present invention provides an alignment film material, which is a mixed solution containing surface-modified silica nanoparticles and polyimide, wherein the surface The mass percentage of the modified silica nanoparticles relative to the polyimide is 0.01wt% to 0.2wt%;

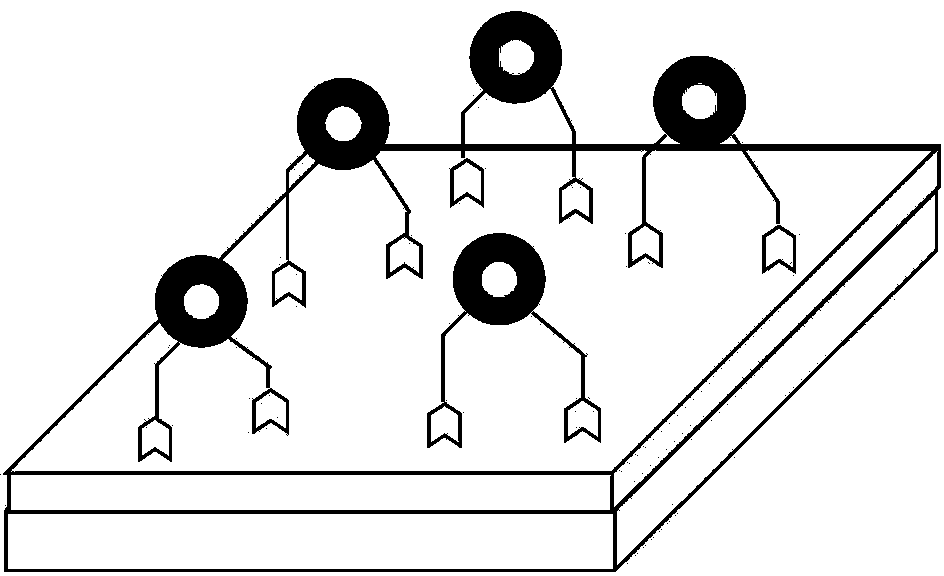

[0121] Wherein, the surface-modified silica nanoparticles are obtained after silica nanoparticles undergo surface modification treatment, which eliminates or reduces the number of hydroxyl groups on the surface of the silica nanoparticles, and the surface modification The silica nanoparticles are anchored on the surface with terminal amino groups (-NH 2 ) linear chain.

[0122] Optionally, the alignment film material may also include a certain amount of non-aqueous organic solvent.

[0123] Using the alignment film material described in this embodiment, a vertically aligned alignment film can be prepared without the use of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com