Efficient and energy-saving linkage dust collection device of moving dumper

A high-efficiency energy-saving dust removal device technology, applied in the field of energy-saving dust removal equipment and dust control, can solve the problems of easy air leakage of the belt sealing device, increase the height and weight of the car body, and affect the dust removal effect, so as to achieve good dust control effect and long service life. Long, high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

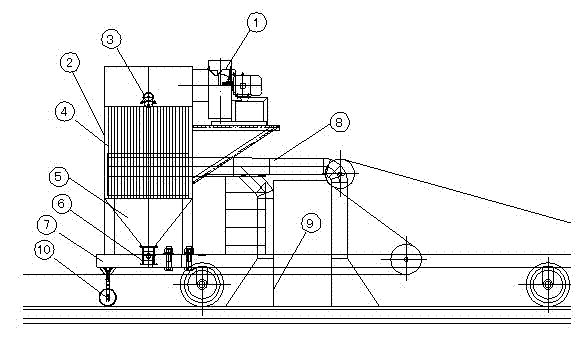

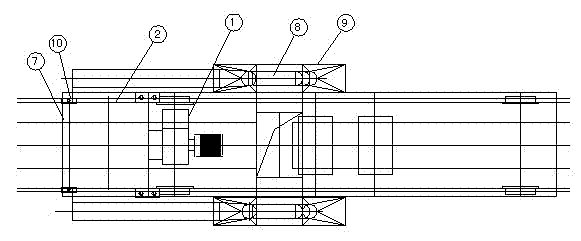

[0028] A high-efficiency and energy-saving mobile unloading vehicle linkage dust removal device of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0029] like figure 1 The structure diagram of a high-efficiency and energy-saving mobile unloading vehicle linkage dust removal device of the present invention is shown and combined with figure 2 It can be seen that a high-efficiency and energy-saving mobile unloading vehicle linkage dust removal device of the present invention is in the linkage support platform 7 at the front of the mobile unloading vehicle, the bag filter 2 installed on the linkage support platform 7, the centrifugal fan 1, and the dust collection cover 9. The dust removal pipeline 8, the vibration cleaning device 3, and the dust collection bucket 5 are composed of a combination; It is located at the lower part of the bag filter 2; the dust collection cover 9 is arranged under both sides of the unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com