A multi-station intelligent bottle unscrambler device

A bottle unscrambler, multi-station technology, applied in conveyor control device, transportation and packaging, conveyor objects, etc., can solve problems such as bottle body damage and deformation, improve efficiency, avoid no-load operation, ensure The effect of full load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

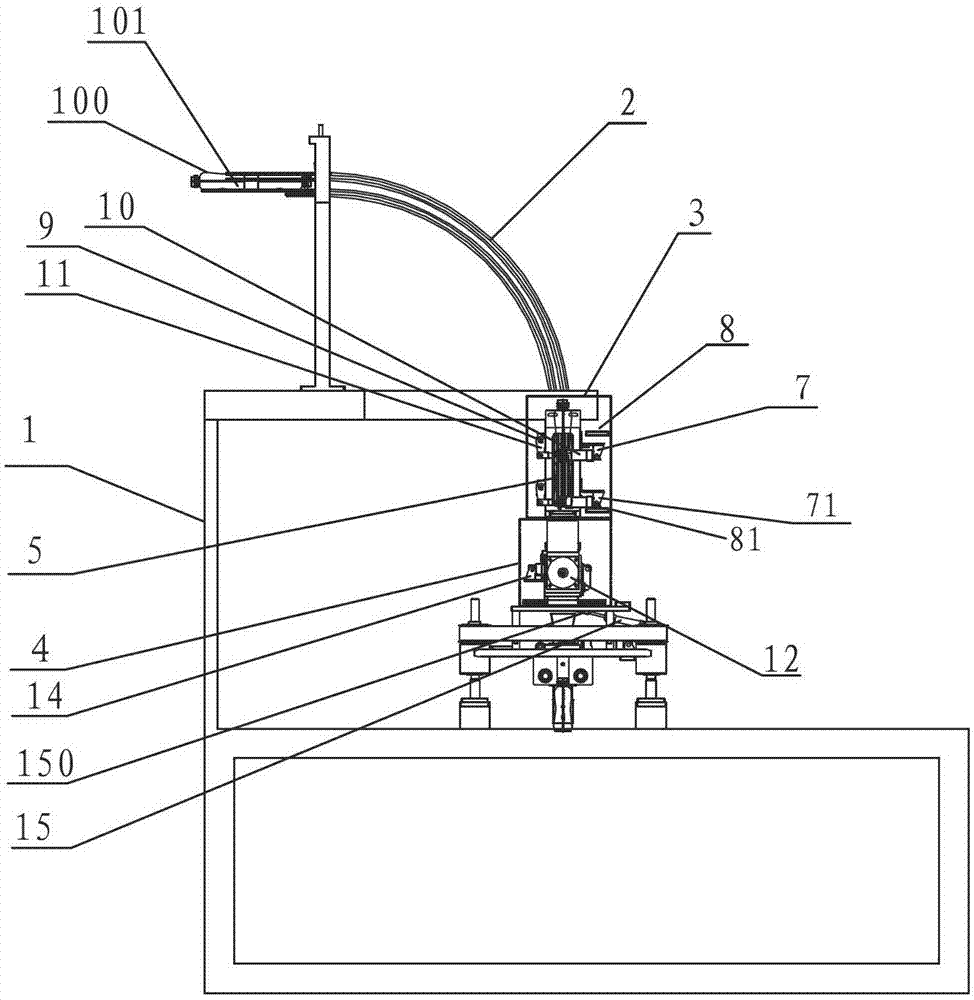

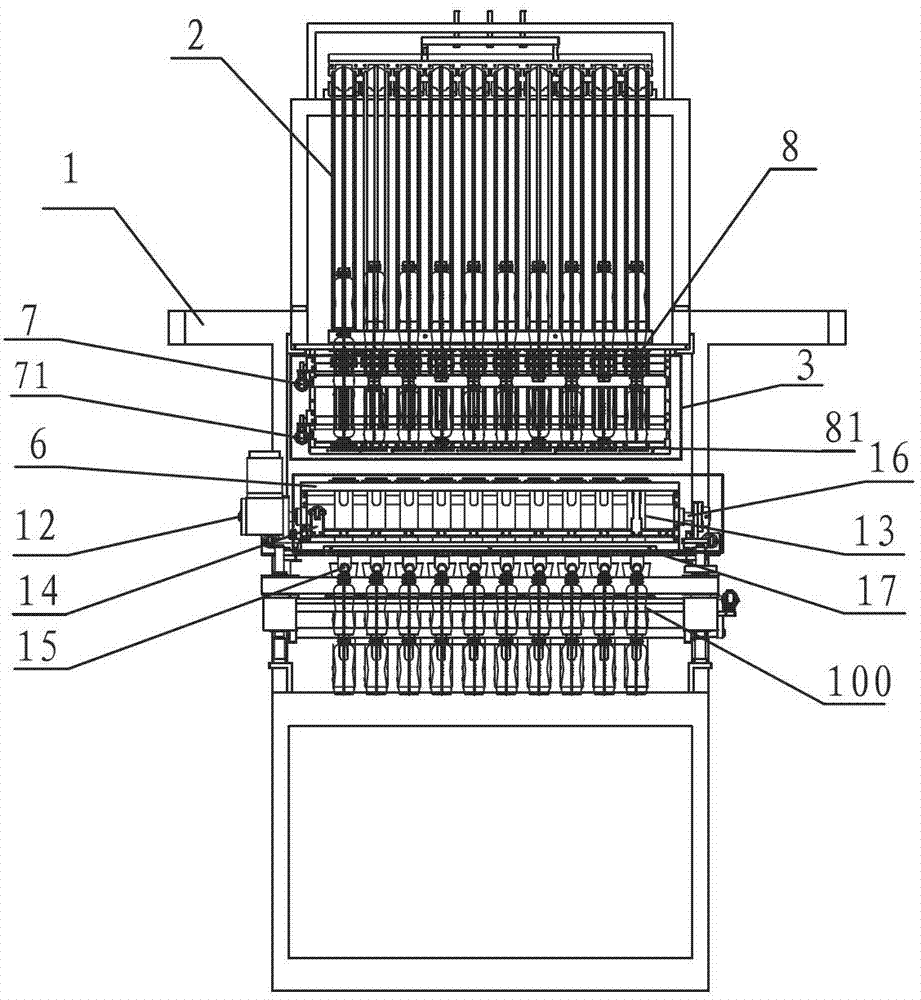

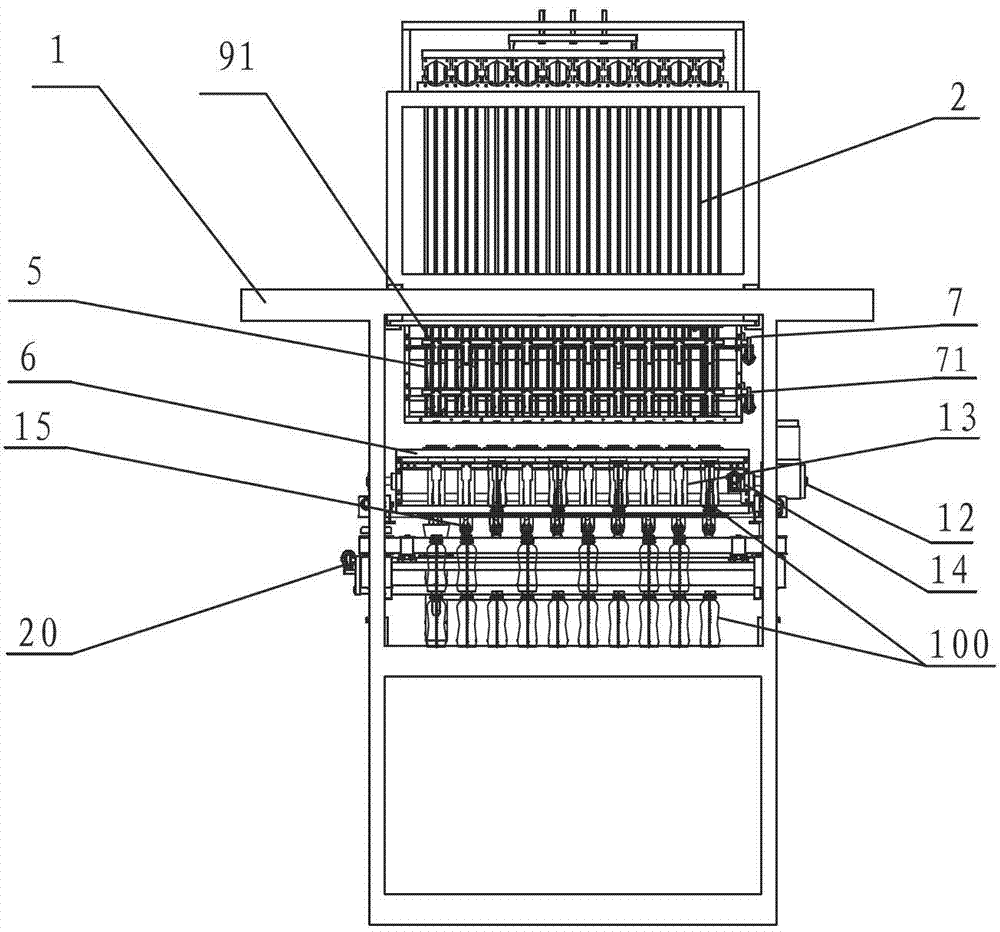

[0016] Refer to attached picture. The present invention comprises a bottle feeding mechanism 3, a rotating bottle unscrambling mechanism 4, a frame 1, and a controller. The bottle feeding mechanism 3 and the rotating bottle unscrambling mechanism 4 are sequentially connected to the frame 1 and connected to the controller. Mechanism 3 includes a positive and negative bottle detection device.

[0017] In this embodiment, the bottle feeding mechanism 3 and the rotating bottle unscrambling mechanism 4 are arranged and fixed on the frame 1 vertically from top to bottom. The bottle feeding mechanism 3 includes a first rail group 2, the first rail group 2 is made up of at least ten bottle conveying rails 5, and each bottle conveying rail is arranged in a square by four smooth-surfaced guide bars parallel to each other. become.

[0018] In addition to the positive and negative bottle detection device, the bottle feeding mechanism also includes a first rail group 2 and a bottle lack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com