Transmission system of rotary-type heat exchanger

A technology of transmission system and heat exchanger, applied in the field of transmission system, can solve problems such as inability to repair and replace faulty motors online, and achieve the effect of improving equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

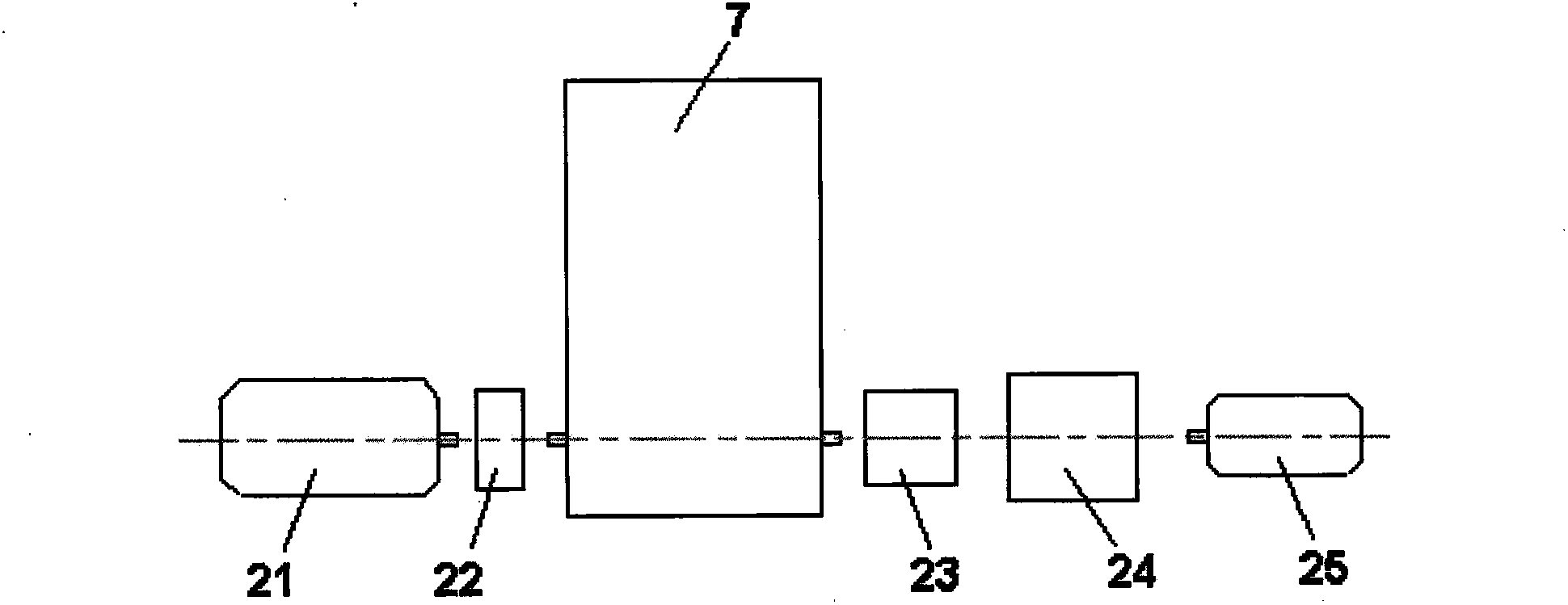

[0042] Such as Figure 5 Shown is the structural schematic diagram of the basic rotary heat exchanger transmission system. The present invention is a transmission system of a rotary heat exchanger. One end of the third reducer 30 is connected to one end of the first magnetic coupling device 32, and the other end of the first magnetic coupling device 32 is connected to the rotating end of the second main motor 31. Connect, the other end of the second main motor 31 is connected with the control box 44, the other end of the third reducer 30 is connected with one end of the second magnetic coupling device 33, the other end of the second magnetic coupling device 33 is connected with the second auxiliary motor 43 The rotating end of the second auxiliary motor 43 is connected with the control box 44, and the control box 44 is connected with the rotor speed measuring system 45 and the power supply 46. Through the control box 44, the steering of the heat exchanger can be changed onlin...

Embodiment 2

[0051] Such as Figure 6 Shown is a schematic structural diagram of a complete rotary heat exchanger drive system. The present invention is a transmission system of a rotary heat exchanger, and the first magnetic coupling device 32 is the second magnetic coupling device 33 . The difference with the ordinary system (i.e. the basic rotary heat exchanger transmission system in Embodiment 1) is that this system does not distinguish between the main and auxiliary drives, and only lies in changing the magnetic coupling 34 on the main driving side of the basic type into a permanent magnetic regulator. Speed type magnetic coupler 40, and configure corresponding adjustment actuator 38 (including executive motor 37 and manual disk 36), other components are the same as common type system.

[0052] The present invention has been verified in practical engineering, and has been run and tested for enough time, and has good application value and prospect.

[0053] (1) Start-up protection:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com