Production process of diamond saw blade formed by compressing granular powders

The invention relates to a diamond saw blade and press forming technology, which is applied in the process steps that can greatly improve the yield of saw blades, and in the field of manufacturing technology of diamond saw blades, and can solve problems such as affecting work efficiency, difficulty in controlling production costs, saw blade breakage, and the like, Achieve significant effect, improve molding degree, and ensure the effect of sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

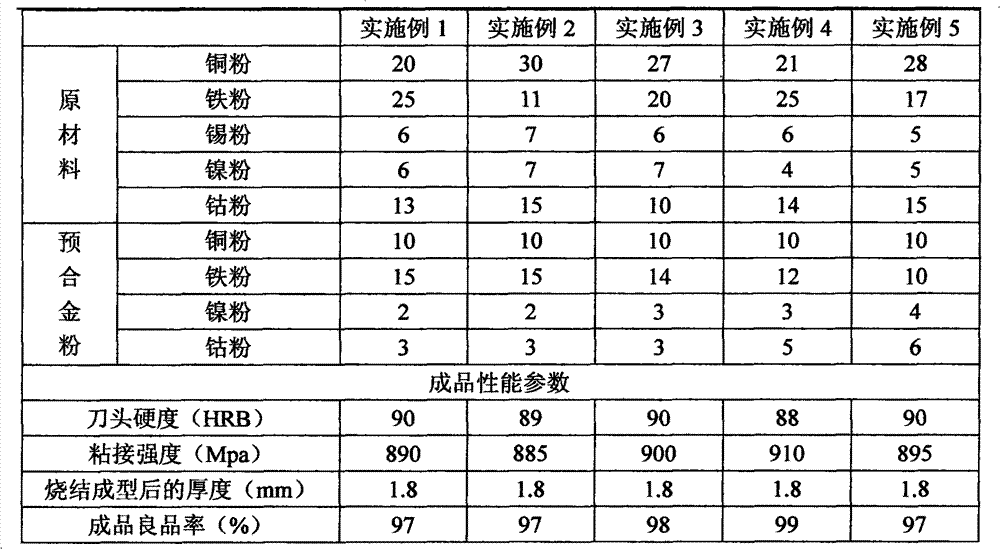

[0014] The production process of the diamond saw blade pressed and formed by granular powder, the steps include: taking copper powder, iron powder, tin powder, nickel powder and cobalt powder as raw materials, adding liquid paraffin for mixing and stirring, and then pressing, sintering and post-processing The key is: the specific steps of the manufacturing process include:

[0015] a. Proportion raw materials by weight percentage, copper powder 20%-30%, iron powder 10%-25%, tin powder 5%-7%, nickel powder 4%-7%, cobalt powder 10%-15%, pre Alloy powder 25-32%;

[0016] b. Add liquid paraffin to the above raw materials, mix and stir for 4-6 hours;

[0017] c. Agglomerate the mixed slurry in cobalt powder, stop the agglomeration when the diameter of the particles is 0.1-0.2mm, screen the particles out with the aid of a sieve, and then dry them to form diamond particles;

[0018] d. Putting the above diamond particles into a pressing mold for pressing to form a regular saw blade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com